Special pure electric airport fire-fighting truck power system and truck

A power system and pure electric technology, applied in the field of vehicles, can solve the problems of slow fire response, poor energy saving and environmental protection, prone to rollover, etc., and achieve the effect of fast response, strong power performance, and not easy to rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

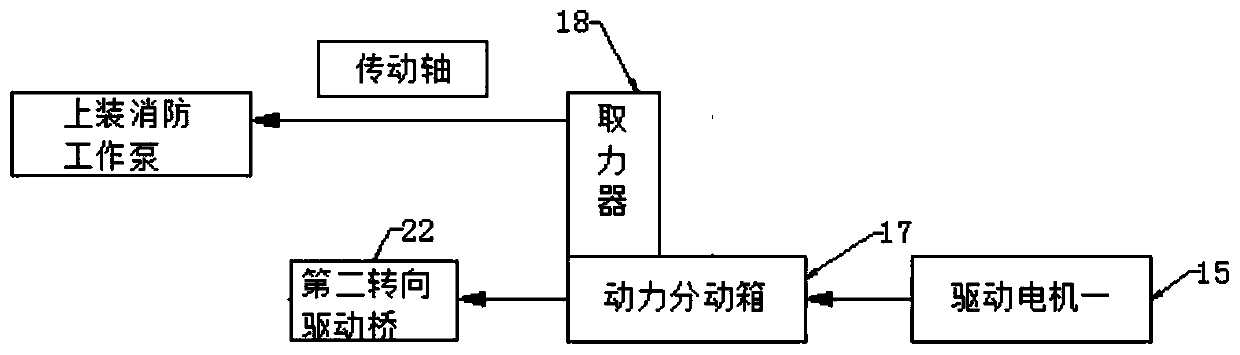

[0072] Such as figure 1 As shown, a pure electric airport-specific fire engine power system includes a driving motor 15, a power transfer case 17, a power take-off 18, and a second steering drive axle 22;

[0073] The driving motor 15 is connected to the power transfer case 17 through a transmission shaft;

[0074] The power transfer case 17 is connected to the second steering drive axle 22 through a transmission shaft;

[0075] The power transfer case 17 transmits power to the bodywork equipment through the power take-off 18.

[0076] The working process and principle of Embodiment 1 of the present invention:

[0077] 1. According to whether power take-offs are used for the bodywork, there are three working methods:

[0078] (1) When driving without taking power, the driving motor 15 transmits the power to the second steering drive axle 22 through the power transfer case 17, so as to realize the demand for driving without taking power;

[0079] (2) Driving power take-off conditions, the ...

Embodiment 2

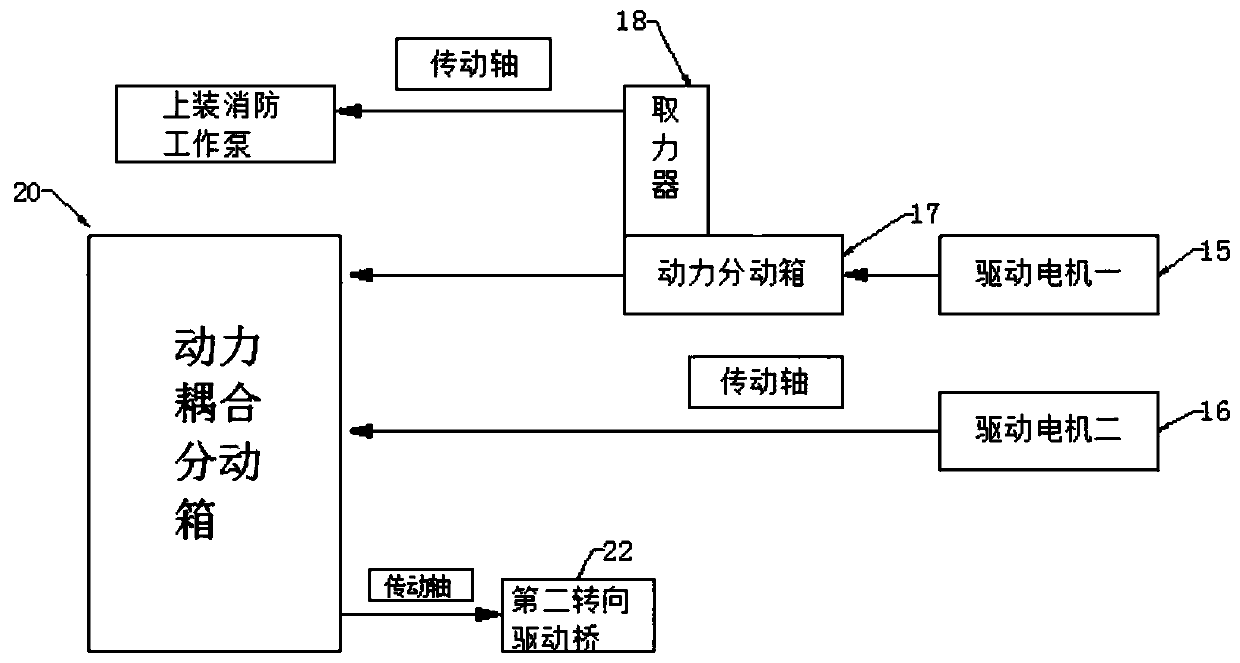

[0082] Such as figure 2 As shown, a pure electric airport special fire truck power system includes a driving motor 15, a driving motor 16, a power transfer case 17, a power take-off 18, a power coupling transfer case 20, and a second steering drive axle 22;

[0083] The driving motor 15 is connected to the power transfer case 17 through a transmission shaft;

[0084] The power transfer case 17 and the two driving motors 16 are both connected to the power coupling transfer case 20 through a transmission shaft;

[0085] The power coupling transfer case 20 is connected to the second steering drive axle 22 through a transmission shaft;

[0086] The power transfer case 17 transmits power to the bodywork equipment through the power take-off 18.

Embodiment 3

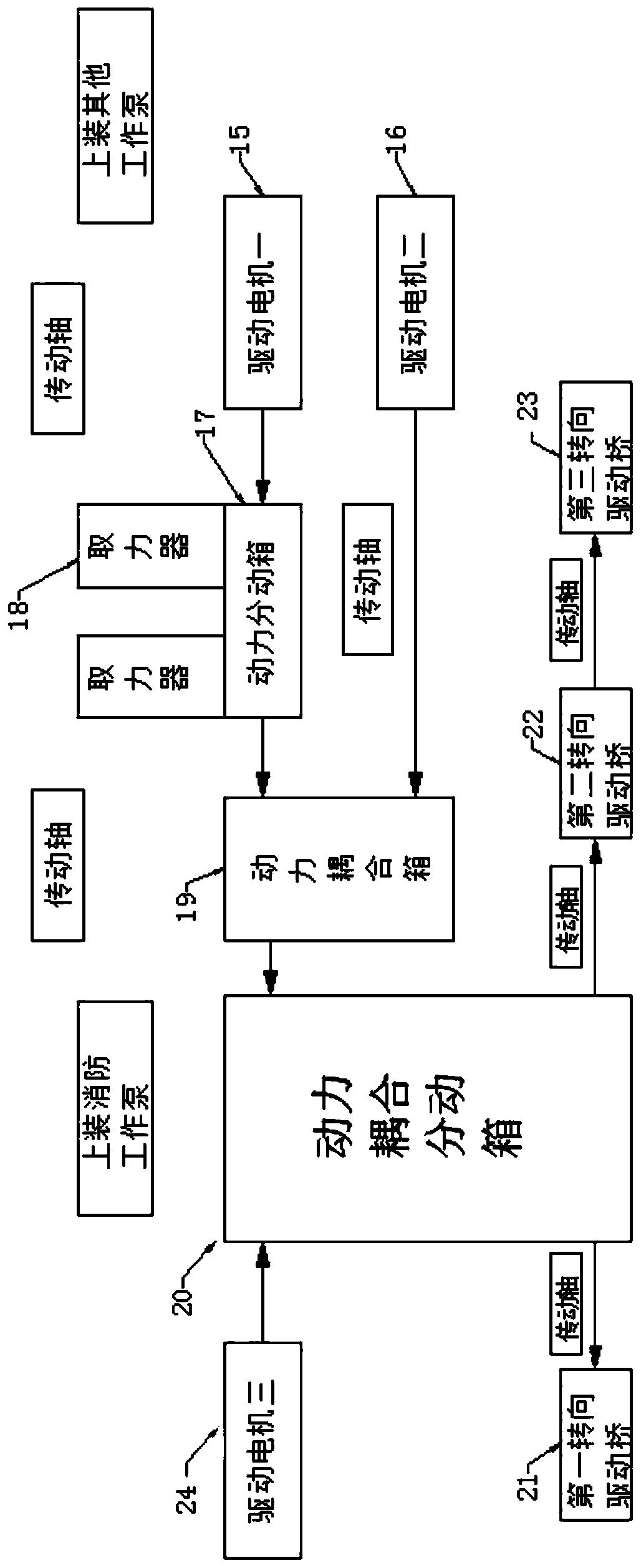

[0088] A power system for a purely electric airport fire truck, including a driving motor 15, a driving motor 16, a power transfer case 17, a power take-off 18, a power coupling transfer case 20, a second steering drive axle 22, and a third steering Drive axle 23;

[0089] The driving motor 15 is connected to the power transfer case 17 through a transmission shaft;

[0090] The power transfer case 17 and the two driving motors 16 are both connected to the power coupling transfer case 20 through a transmission shaft;

[0091] The power coupling transfer case 20 is connected to the second steering drive axle 22 through a transmission shaft, and the second steering drive axle 22 is connected to the third steering drive axle 23 through a transmission shaft;

[0092] The power transfer case 17 transmits power to the bodywork equipment through the power take-off 18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com