Vertical overturning carrier device

A vertical flipping and carrier technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of poor positioning effect, long time-consuming, unstable structure, etc., and achieve high processing efficiency, short processing time and stable operation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

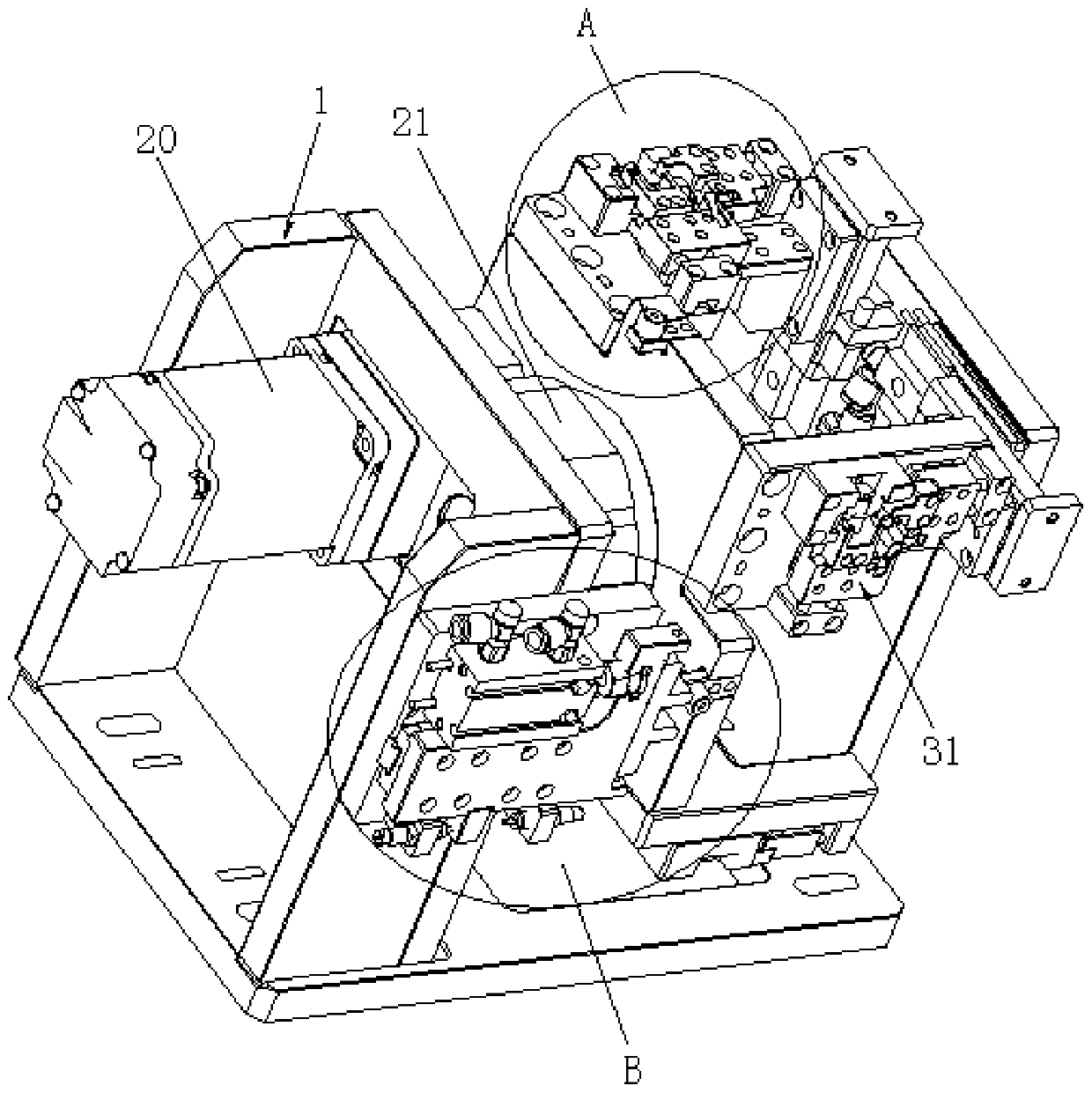

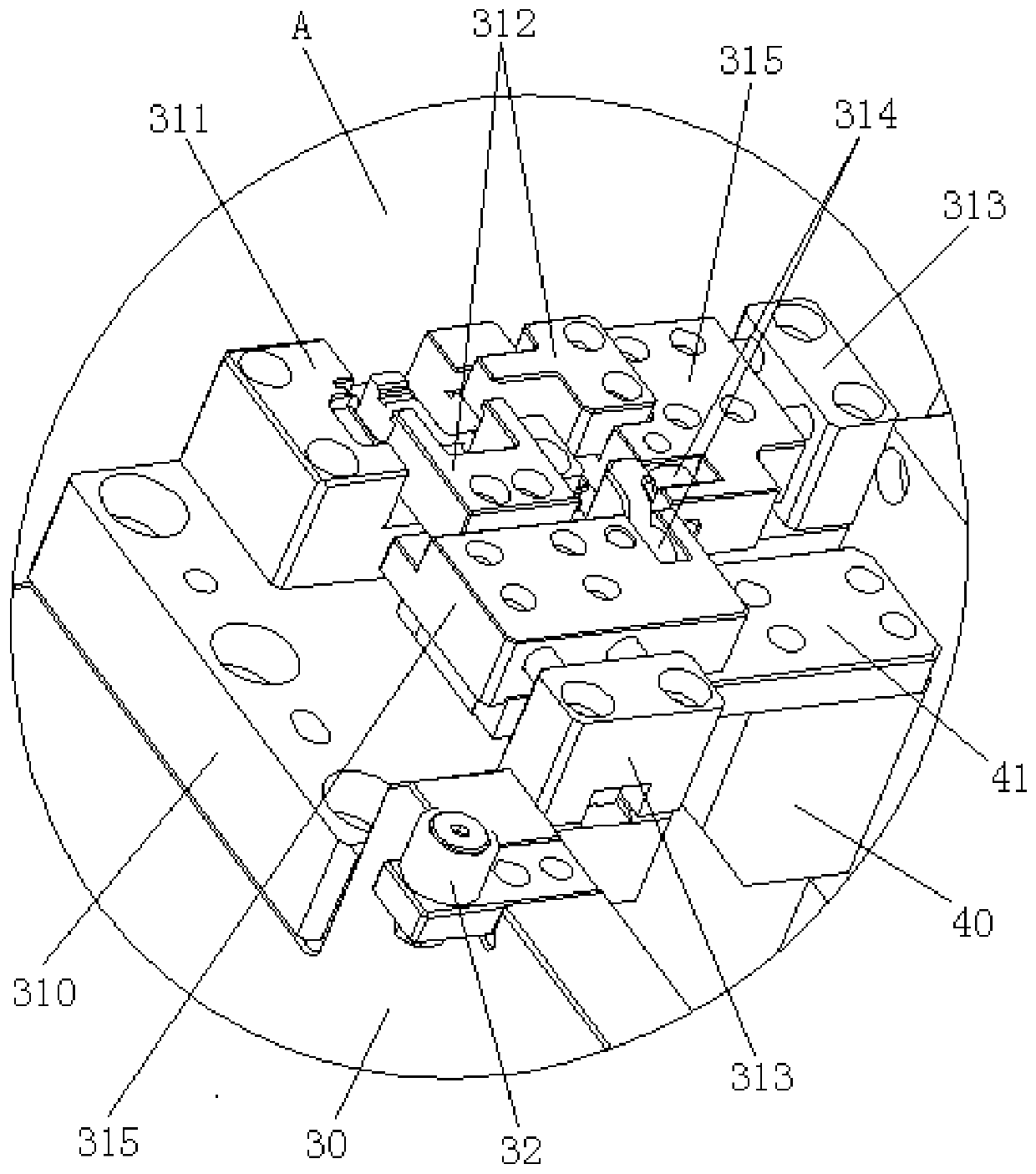

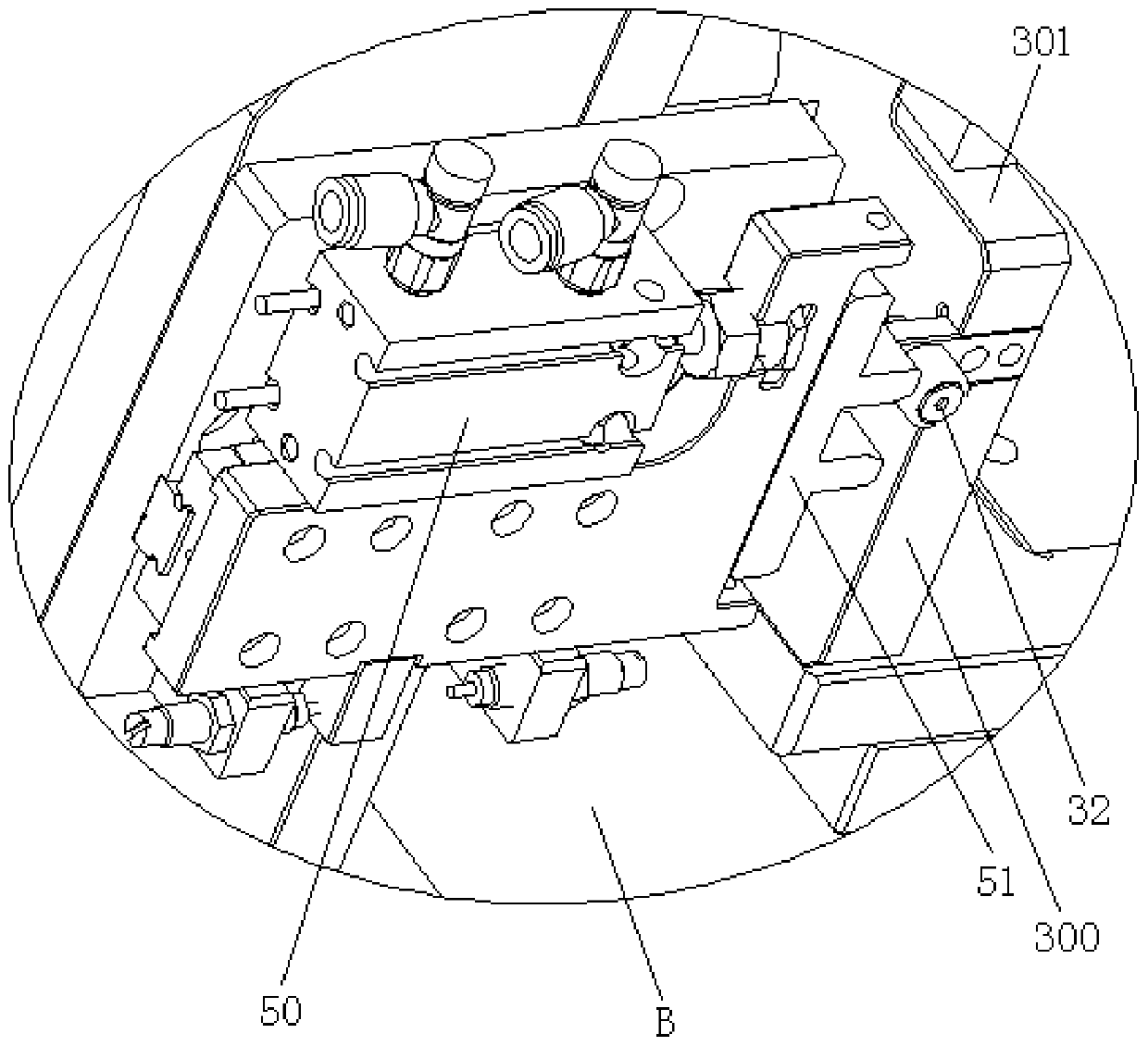

[0040] Please refer to the attached figure 1 to attach Figure 5 As shown in FIG. 1 and 2 , respectively, are three-dimensional structural schematic diagrams of the vertically flipping carrier device of the present invention under two different viewing angles, and three partial enlarged structural schematic diagrams.

[0041] The vertical turning carrier device of the present invention includes a machine base 1, a power mechanism and a carrier mechanism, the power mechanism has a motor 20 positioned and installed on the machine base 1, and the carrier mechanism has a mounting plate 30 and a plurality of carriers 31, the mounting plate 30 is positioned and connected to the power output shaft of the motor 20, and each carrier 31 has a carrier plate 310 positioned and mounted on the mounting plate 30, a Positioning is installed on the carrier 310 for the carrier 311 for product placement, and at least two clamping blocks 312 movably installed on the carrier 310, and at least two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com