Multi-sequin device and embroidery machine with same

A technology for sequins and sequins, which is applied in the direction of automatic control embroidery machines, embroidery machines, embroidery machine mechanisms, etc., to achieve the effects of prolonging service life, high transmission efficiency, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

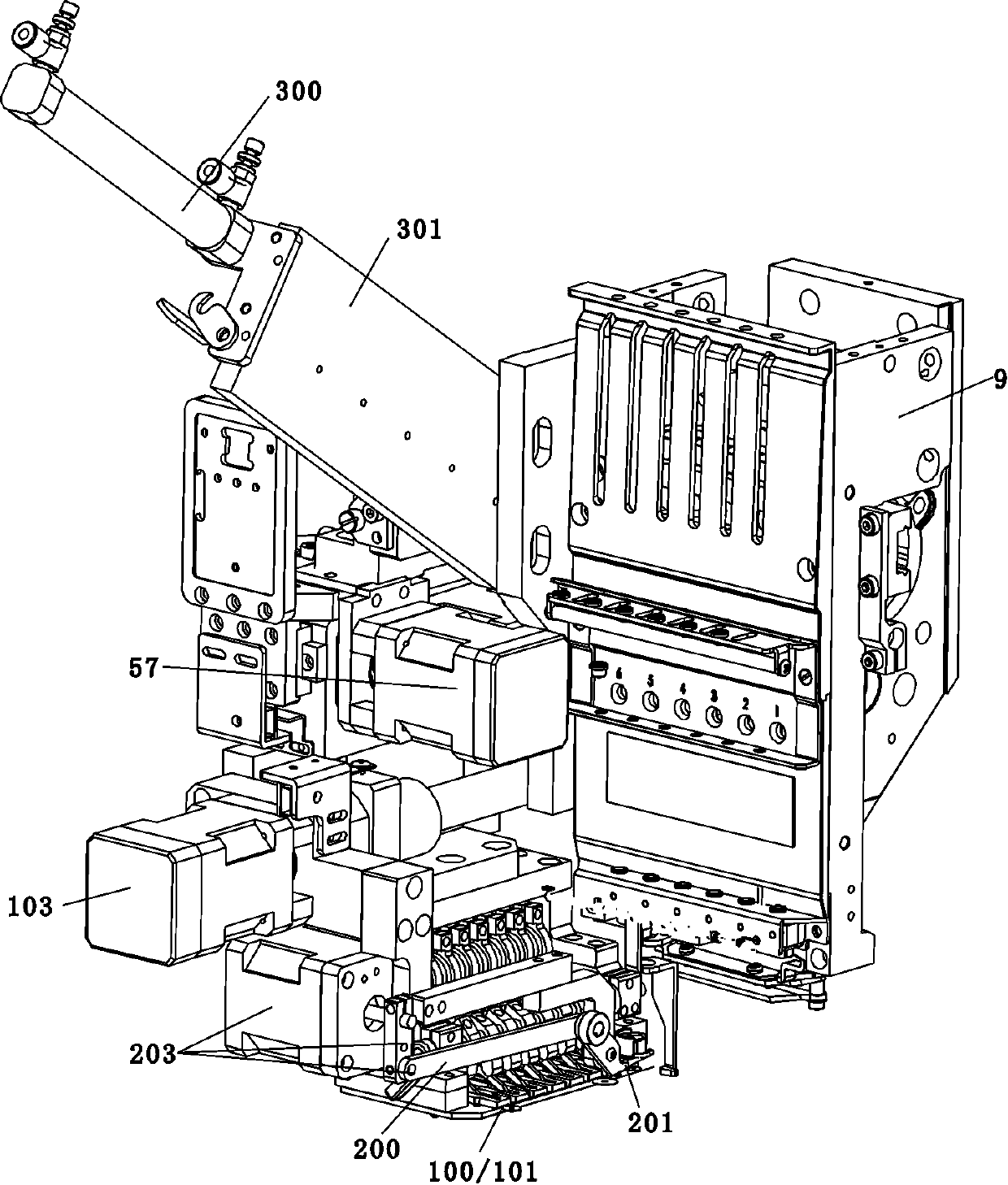

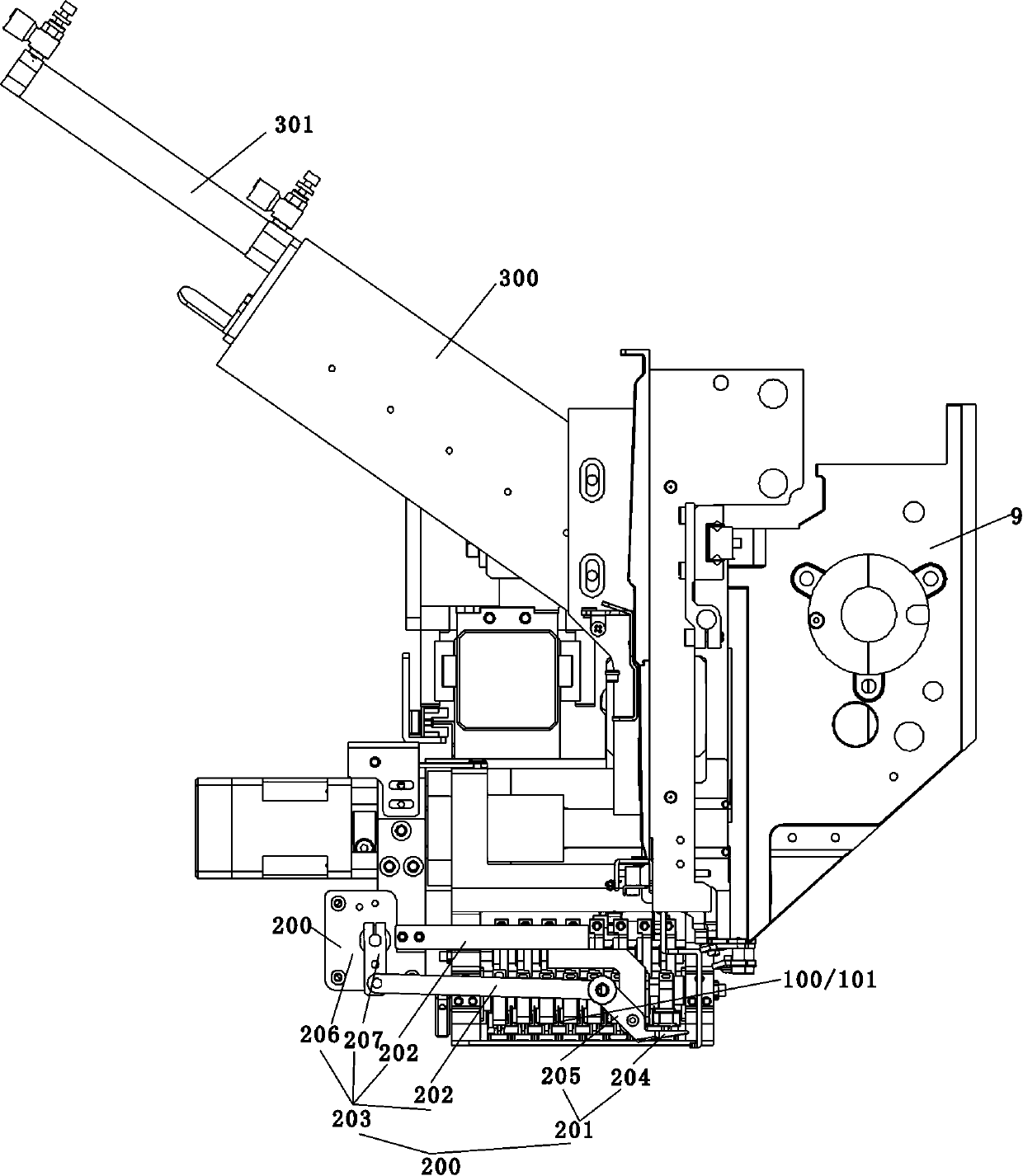

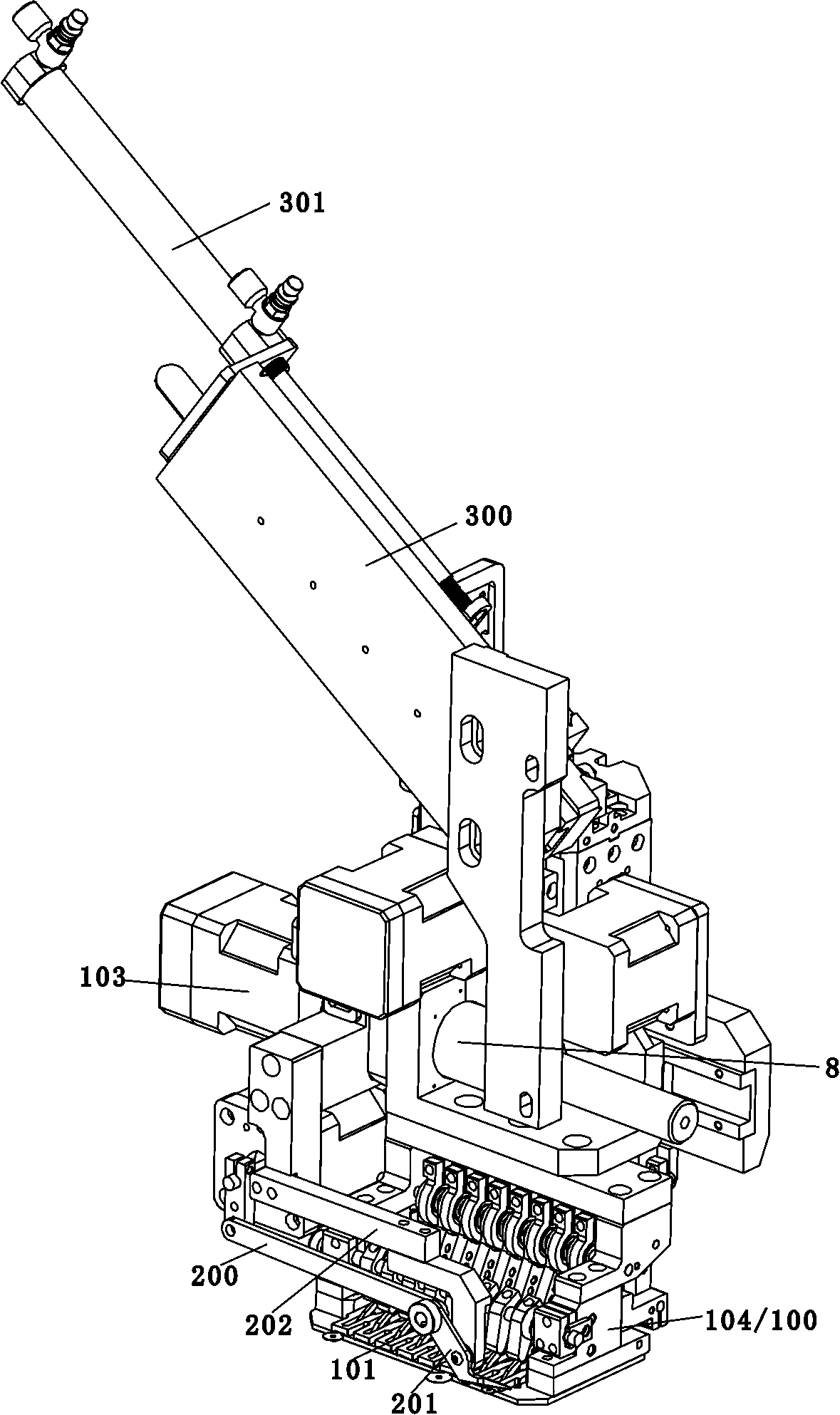

[0030] see Figure 1-7 , a multi-sequin device, including a sheet feeding mechanism 100 with at least two sets of sheet feeding devices 101 arranged side by side, a cutter assembly 200 matched with the sheet feeding mechanism 100, and a sheet feeding driver that drives the corresponding sheet feeding device 101 to feed the sheet 102. A piece-feeding station arranged on the piece-feeding mechanism 101, switch the corresponding or any group of piece-feeding device 101 to the piece-feeding station, and the piece-feeding driver 103 that cooperates with the embroidery needle. The cutter assembly 200 includes a The cutting knife 201 for slicing in cooperation with the sheet feeder 101 located at the station at the sheet station, the cutting knife 201 is provided with a knife rest 202 for installing and positioning the cutting knife 201 and a slicing driver 203 for driving the cutting knife 201 to slice. It can also include a controller, which can be independently set to control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com