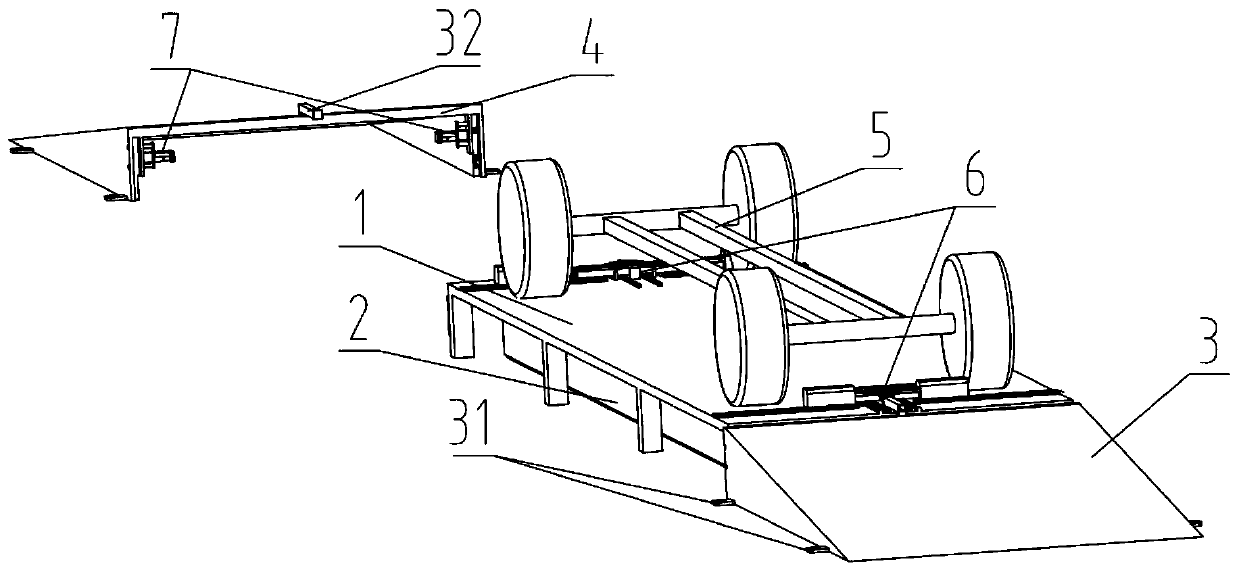

Vehicle pallet limiting mechanism and automated guided vehicle (AGV) transferring platform comprising same

A limit mechanism and pallet technology, which is applied in the direction of buildings, building types, buildings, etc. where cars are parked, can solve the problems of inconvenient limit, inconvenient and smooth transfer, and achieve smooth transfer, reliable fixation, tire limit and so on. bit accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

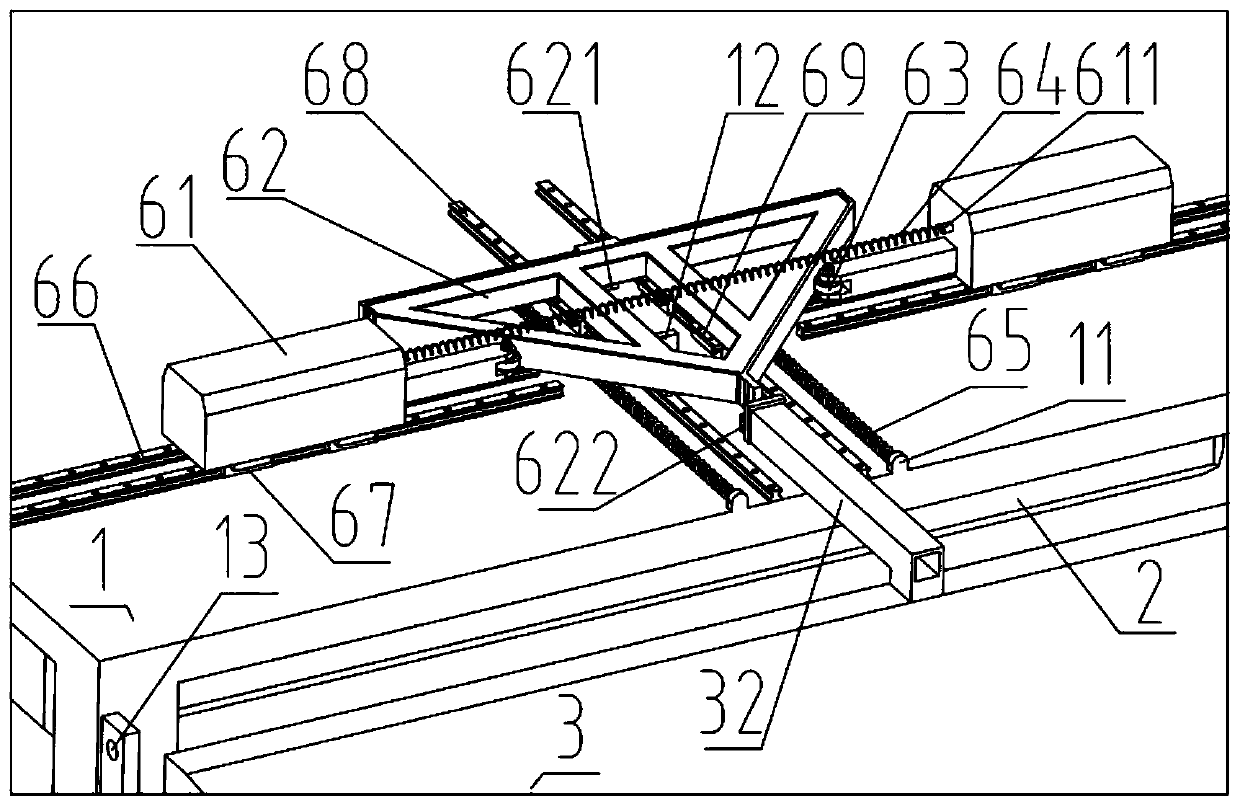

[0034] The present invention will be further described in conjunction with the accompanying drawings.

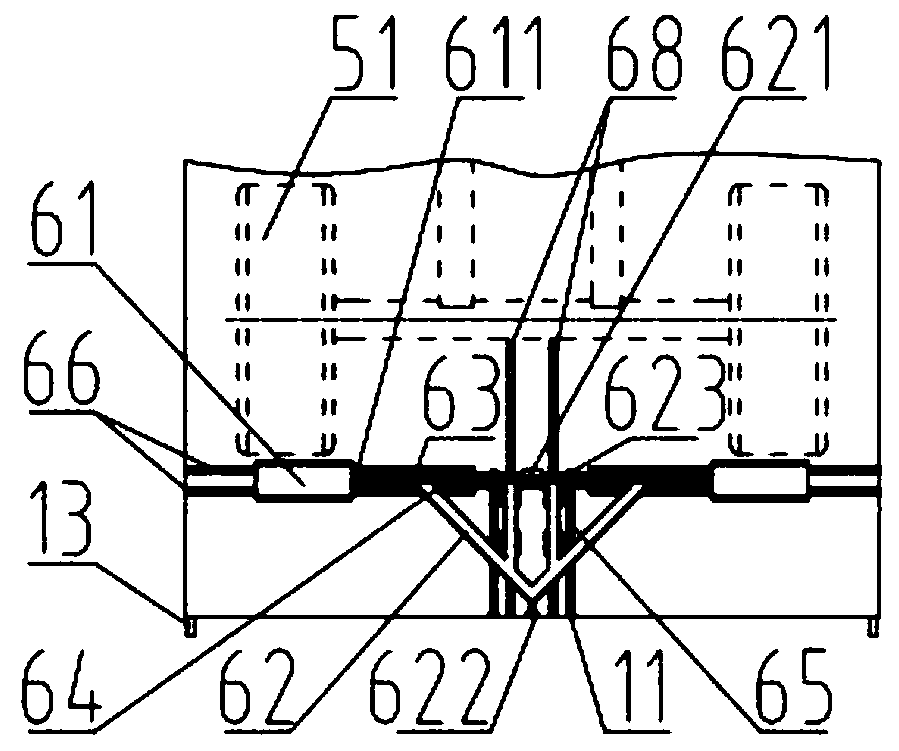

[0035] A vehicle pallet limit mechanism, comprising: two tire limit stops (61), a limit tripod (62), a tripod limit baffle (621), two rollers (63), a limit stop Extension spring (64), 2 tripod extension springs (65), 4 limit block slide rails (66), 8 limit block slide blocks (67), 2 tripod slide rails (68), 4 a tripod slide block (69);

[0036]2 tire limit blocks (61) are connected by limit block extension springs (64), and 4 limit block slide blocks (67) are arranged below each tire limit block (61), and the limit block Each tire limit block (61) of slide block (67) can be slidably connected with 2 limit block slide rails (66). The limit tripod (62) is arranged between two tire limit blocks (61), the tripod slide rail (68) is arranged below the limit tripod (62), and 4 sets of limit tripods (62) are arranged below Tripod slide block (69), through tripod slide block (69) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com