Calibration method for tire balance system

A tire balance and calibration method technology, applied in the field of tire balance detection, can solve problems such as affecting measurement results and system calibration errors, and achieve the effects of reducing process requirements, eliminating unbalance, and measuring accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

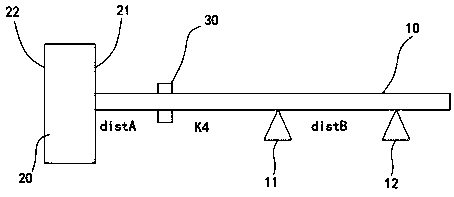

[0014] Please refer to figure 1 , a calibration method for a tire balancing system, suitable for a tire balancing machine, comprising the following steps:

[0015] (1) Install the first pressure sensor 11 and the second pressure sensor 12 under the main shaft 10, install the screw rod, start the motor, and obtain the vector data AO and the second pressure sensor 11 of the first pressure sensor 11 in this state when the main shaft 10 is idling. The vector data BO of the pressure sensor 12 needs to be subtracted from the vector data AO and B0 in the actual unbalance test to eliminate the unbalance of the main shaft.

[0016] Fix a tire 20 on the main shaft 10 flanges, obtain the distance distA between the tire 20 and the measuring ruler 30, the width wid of the tire 20, the radius R of the tire 20, the distance distB between the first pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com