A Dynamic Threshold Early Warning Method for State Monitoring of Moving Equipment

A technology of dynamic threshold and dynamic equipment, applied in measurement devices, testing of machine/structural components, instruments, etc., can solve problems such as deterioration, false early warning, and enterprise loss, and achieve the effect of reducing false alarm rate and eliminating acquisition errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

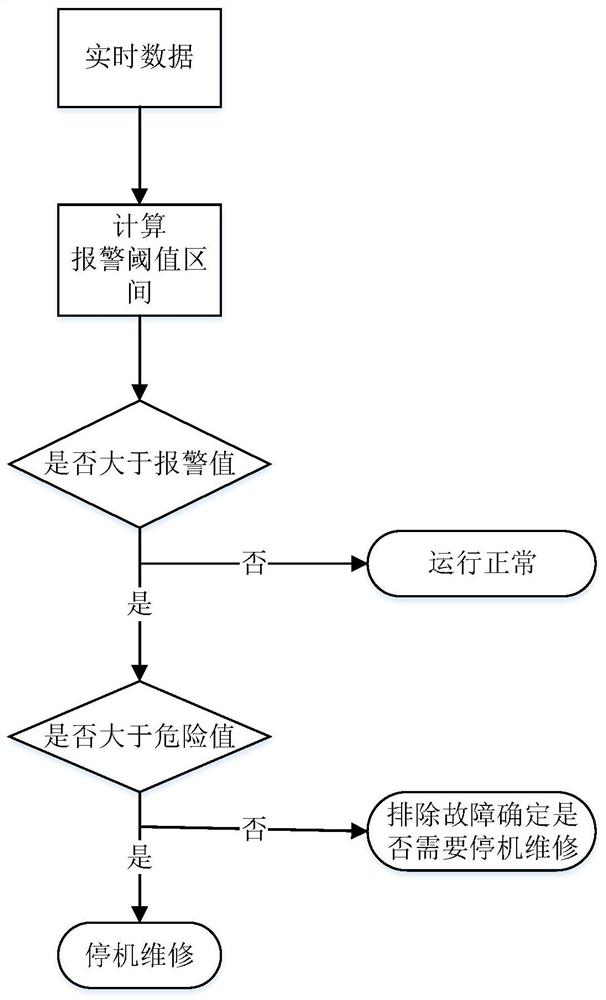

AI Technical Summary

Problems solved by technology

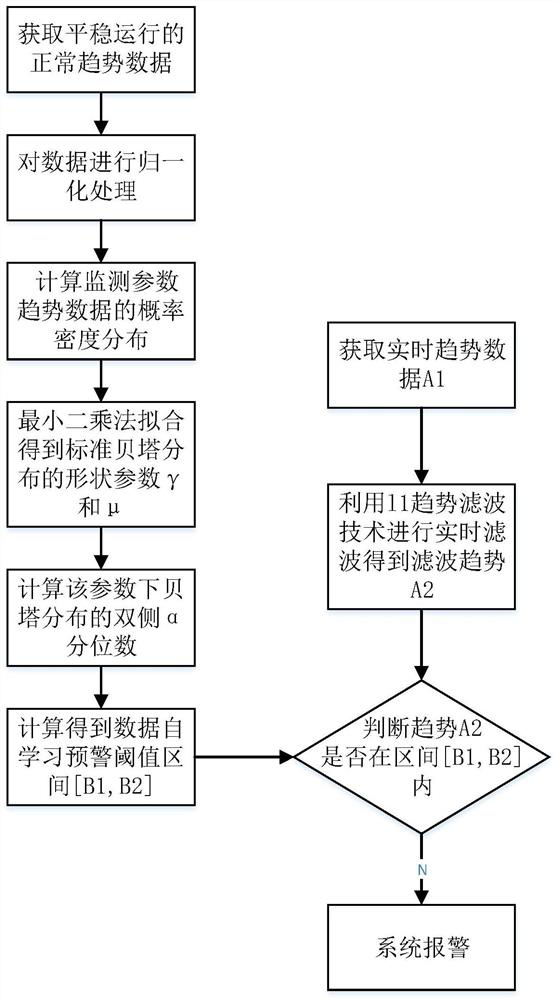

Method used

Image

Examples

Embodiment 1

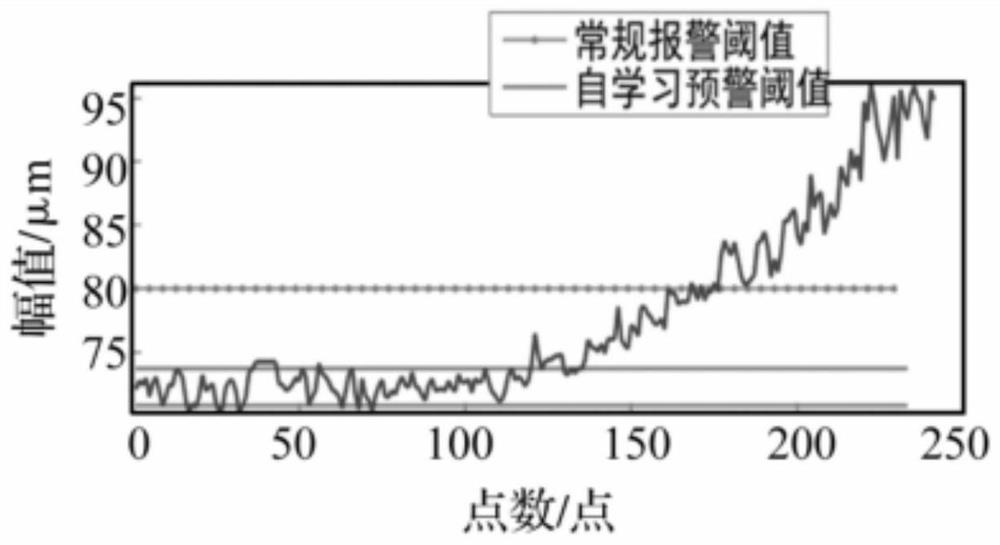

[0043] The conventional alarm value of a flue gas turbine in an enterprise is 80 μm, and the danger value is 100 μm. The monitoring trend of a measuring point of the unit began to climb slowly from the beginning of June 2017. Before that, the trend of the measuring point had been stable at about 73 μm. By the beginning of July 2017, it had climbed to about 95 μm, and the trend had climbed abnormally by 22 μm within a month. After checking the cause of the failure, it was found that the flue gas contained a catalyst, which made the catalyst gradually adhere to the blades of the hood, resulting in a gradual increase in the imbalance, resulting in a slow rise in the trend.

[0044] Calculate the dynamic self-learning early warning threshold in the normal operation stage according to the dynamic self-learning early warning threshold algorithm. When α=0.05, the two shape parameters of the fitted Beta distribution are respectively γ=2.7256 and η=2.4191. The early warning threshold of...

Embodiment 2

[0047] The sudden failure of a compressor in a certain company was caused by the fact that the compression medium was not clean. During long-term operation, dirt accumulated on the blades. The instant the dirt fell off, it caused the rotor unbalance to change, resulting in a sudden change in the vibration trend.

[0048] Based on the dynamic threshold warning method for dynamic equipment state monitoring proposed in this patent, the dynamic self-learning threshold in the normal operation stage is calculated. When α=0.05, the two shape parameters of the fitted Beta distribution are γ=1.9181 and η respectively. =2.6425, and then the lower threshold Thd1=34.9532 and the upper limit Thd2=41.7177 of the trend data are obtained, that is, the self-learning alarm threshold range is [34.9532,41.7177]. Then use the l1 trend filtering technology to filter the vibration trend data to obtain the vibration trend of the moving equipment without fluctuation interference.

[0049] Such as Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com