Meat detection sample thawing device

A sample and meat technology, applied in the field of food testing equipment, can solve the problems of affecting the detection efficiency, time-consuming, time-consuming and labor-intensive, etc., and achieve the effect of improving the thawing efficiency and increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

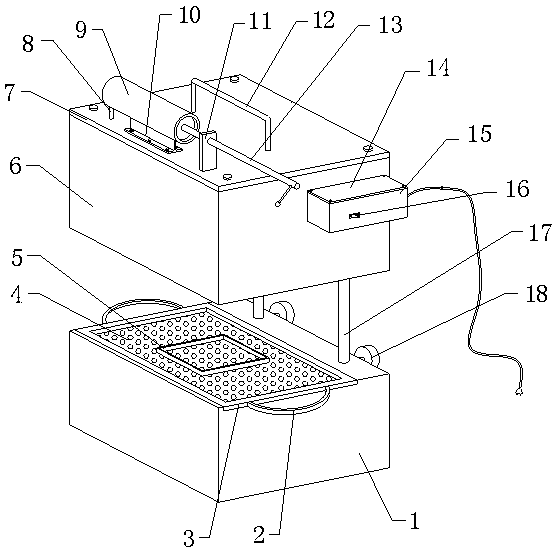

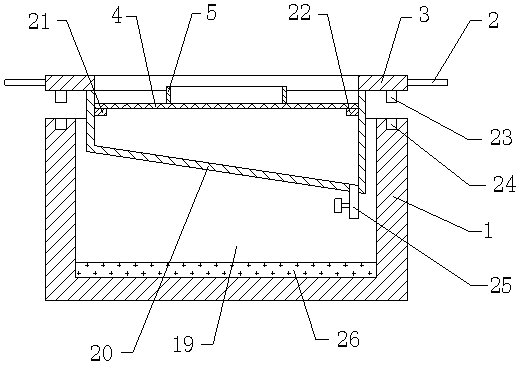

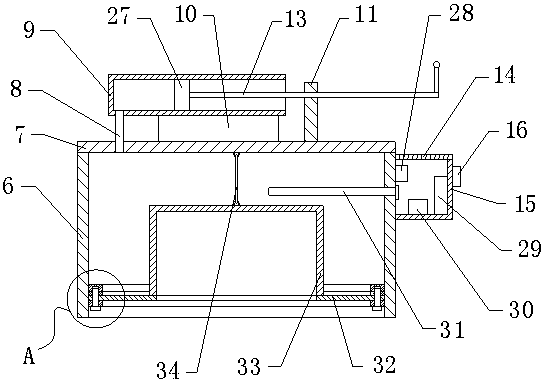

[0023] see Figure 1 to Figure 5 , the present invention provides a technical solution: a meat testing sample thawing device, including a base 1, a loading assembly is installed in the base 1, and the loading assembly includes a handle 2, a frame 3, a porous plate 4, a limit frame 5, Groove 19, liquid collection box 20, retaining bar one 21, retaining bar two 22, limit rod 23, limit hole 24 and water-absorbing sponge 26, base 1 upper end surface installs thawing assembly, thawing assembly includes box body 6, box cover 7. Connecting pipe 8, cylindrical body 9, support plate 10, fixed plate 11, threaded rod 13, cover plate 14, electrical box 15, ship type switch 16, support rod 17, fastening bolt 18, piston 27, heating rod 31 , rectangular frame 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com