Small hole expansion test device and test method thereof

A test device, expander technology, applied in the direction of measuring device, using stable tension/pressure test material strength, soil test, etc., can solve the expensive centrifuge test, cylindrical hole and spherical hole expansion and contraction test research Few, no model test design and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

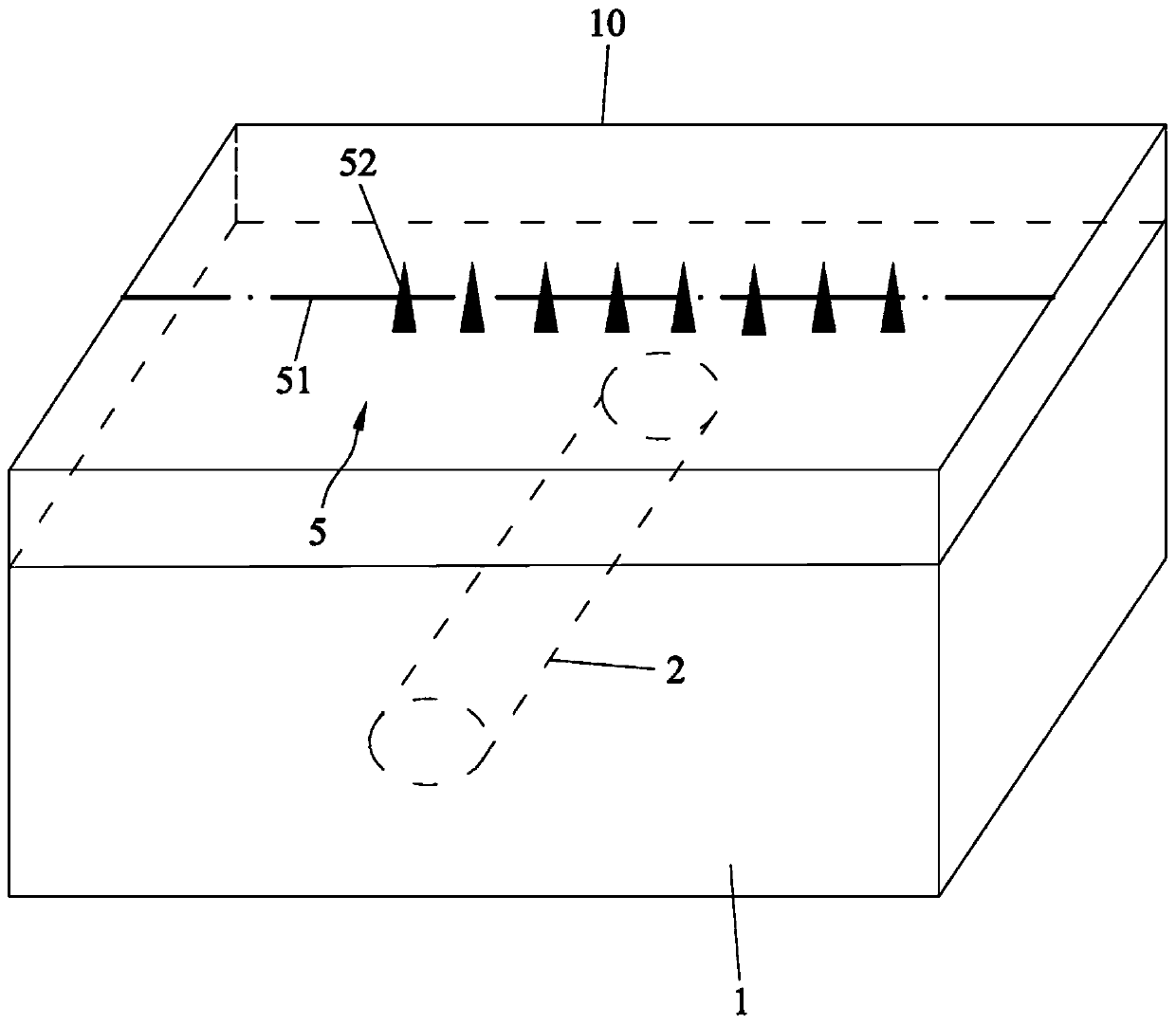

[0064] The present invention carries out the process of cylindrical small hole expansion simulation test, comprises the steps:

[0065] 1) Fill the lower layer of soil (saturated soft clay) into the model box 1 as required, insert the second end cap 24 of the cylindrical expander 2 into one of the positioning holes, and snap the first end cap 23 into the model The other positioning hole of the box 1 is used to keep the cylindrical dilator 2 placed horizontally and securely and sealed;

[0066] 2) Open the water inlet control valve 61, and open the water outlet control valve 71 at the same time, fill the elastic membrane 21 of the dilator 2 with water until the elastic membrane 21 keeps the surface even (the outer diameter of the elastic membrane in this state is its initial outer diameter). diameter), and after the gas in the closed space 20 is exhausted from the water outlet pipe 7, close the water inlet control valve 61, stop water injection and check whether the closed spac...

Embodiment 2

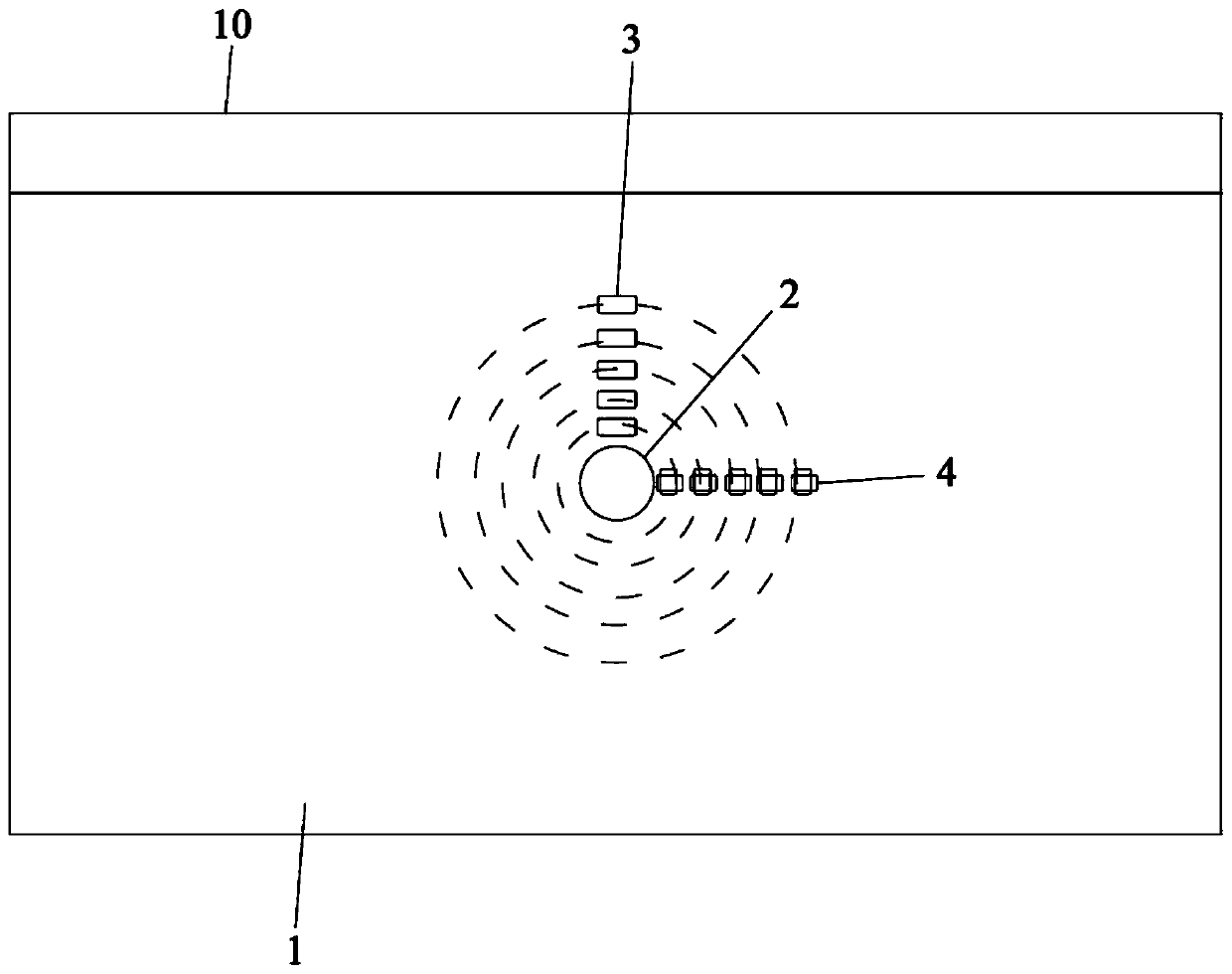

[0071] The present invention carries out the process of cylindrical aperture shrinkage simulation test, comprises the following steps:

[0072] (1) After filling the lower layer of soil (saturated soft clay) into the model box 1 as required, insert the second end cover 24 of the cylindrical expander 2 into a positioning hole, and snap the first end cover 23 into the model box 1 to keep the cylindrical dilator 2 placed horizontally and securely and sealed;

[0073] (2) Open the water inlet control valve 61, and open the water outlet control valve 71 at the same time, fill the elastic membrane 21 of the dilator 2 with water until the elastic membrane 21 keeps the surface even, and exhaust the gas in the closed space 20 from the water outlet pipe 7 Finally, close the water inlet control valve 61, stop water injection and check whether the closed space 20 leaks, if there is no water leakage, then close the water outlet control valve 71, and open the water inlet control valve 61 to...

Embodiment 3

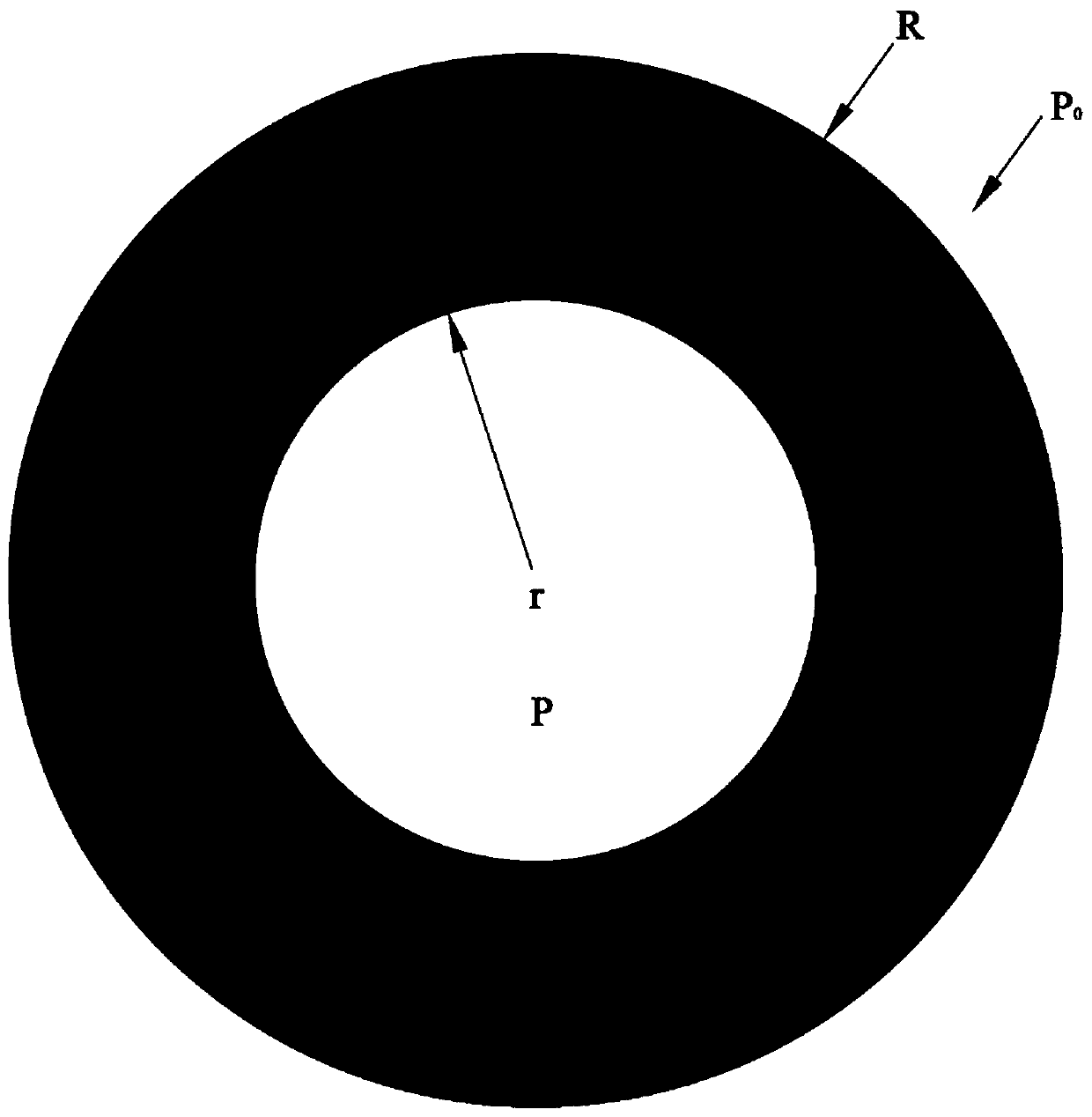

[0078] The present invention carries out the process of spherical small hole expansion simulation test, comprises the steps:

[0079] A. After filling the lower layer of soil (saturated soft clay) into the model box 1 as required, reserve a small groove for the spherical expander, place the spherical expander in the small groove, and keep the spherical expander placed horizontally and The water injection pipe 6 faces upwards;

[0080] B. Open the water inlet control valve 61 of the spherical expander, and open the water outlet control valve 71 at the same time, so that the rubber membrane of the expander 2 is filled with water until the elastic rubber membrane is kept close to a perfect circle, and the gas in the closed space 20 flows from the water outlet pipe 7 After draining, close the water inlet control valve 61 and check whether there is water leakage. If there is no water leakage, then after closing the water outlet control valve 71, open the water inlet control valve 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com