Descaling device for oilfield water pouring pipe and operation method

A technology of oil field water injection and round sleeves, which is applied to cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., which can solve the problems of inconvenient cleaning, inability to use chemicals to clean, inconvenient cleaning of scale, etc., and achieve heat dissipation effect Good, it is convenient to enter and exit the oilfield water injection pipe, and it is convenient to turn forward and reverse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

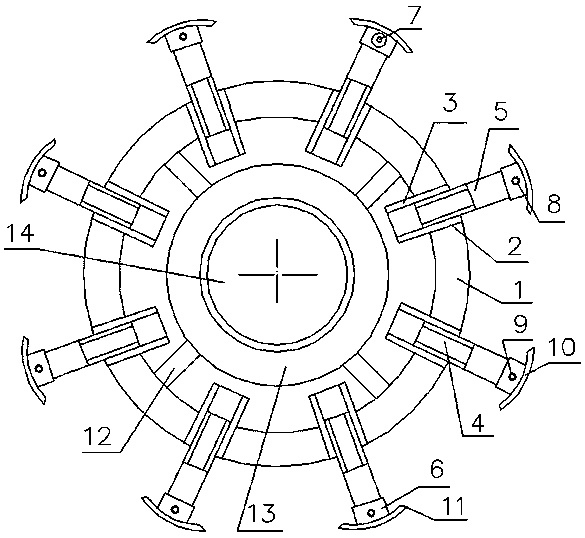

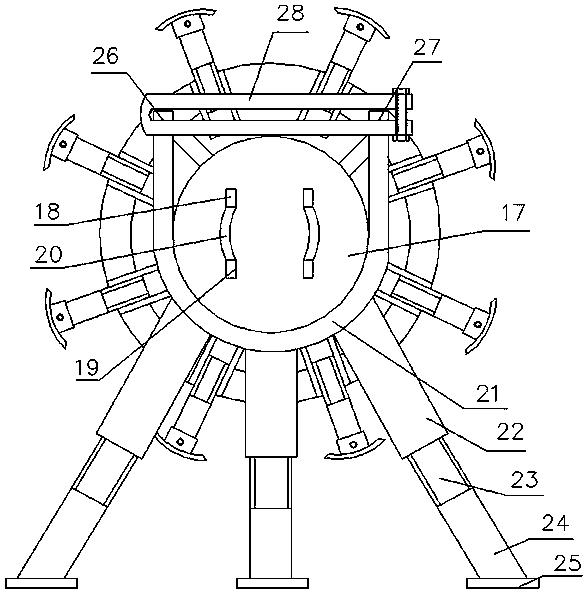

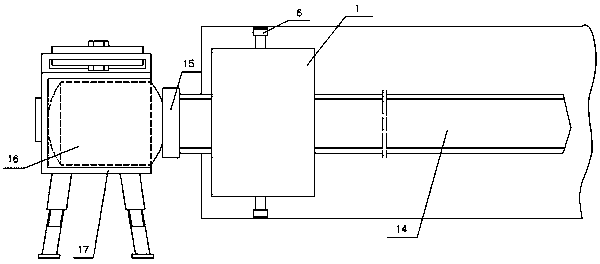

[0023] An oil field water injection pipe descaling device, which consists of: a circular sleeve 1, a group of sockets 2 are opened around the circumference of the circular sleeve, the sockets are welded with a horizontal threaded sleeve 3, and the horizontal threaded sleeve is connected to a horizontal Threaded rod 4, the horizontal threaded rod is connected to the cross strut 5, the outer side of the cross strut is inserted into the fixing sleeve 6, the described cross strut has a fixing hole 7, and the described fixing sleeve has a concentric fixing Hole 8, the fixed hole coincides with the concentric fixed hole and is fixed by bolt 9, the fixed sleeve is welded with arc-shaped scraper 10, and the top and bottom of the arc-shaped scraper have cutting edges 11, The circular sleeve is connected with a group of support plates 12 around the circumference, the support plate is connected with the screw sleeve 13, the screw sleeve is connected with the screw rod 14, the screw rod is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com