Electric hoist for single-beam crane

A technology for electric hoists and cranes, applied in the field of electric hoists for single-girder cranes, can solve the problems of increasing the safety factor of electric hoists and large loads, and achieve the effect of enhancing transmission strength and rigidity and enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further elaborate the present invention in conjunction with the specific embodiments. figure 1 as the benchmark.

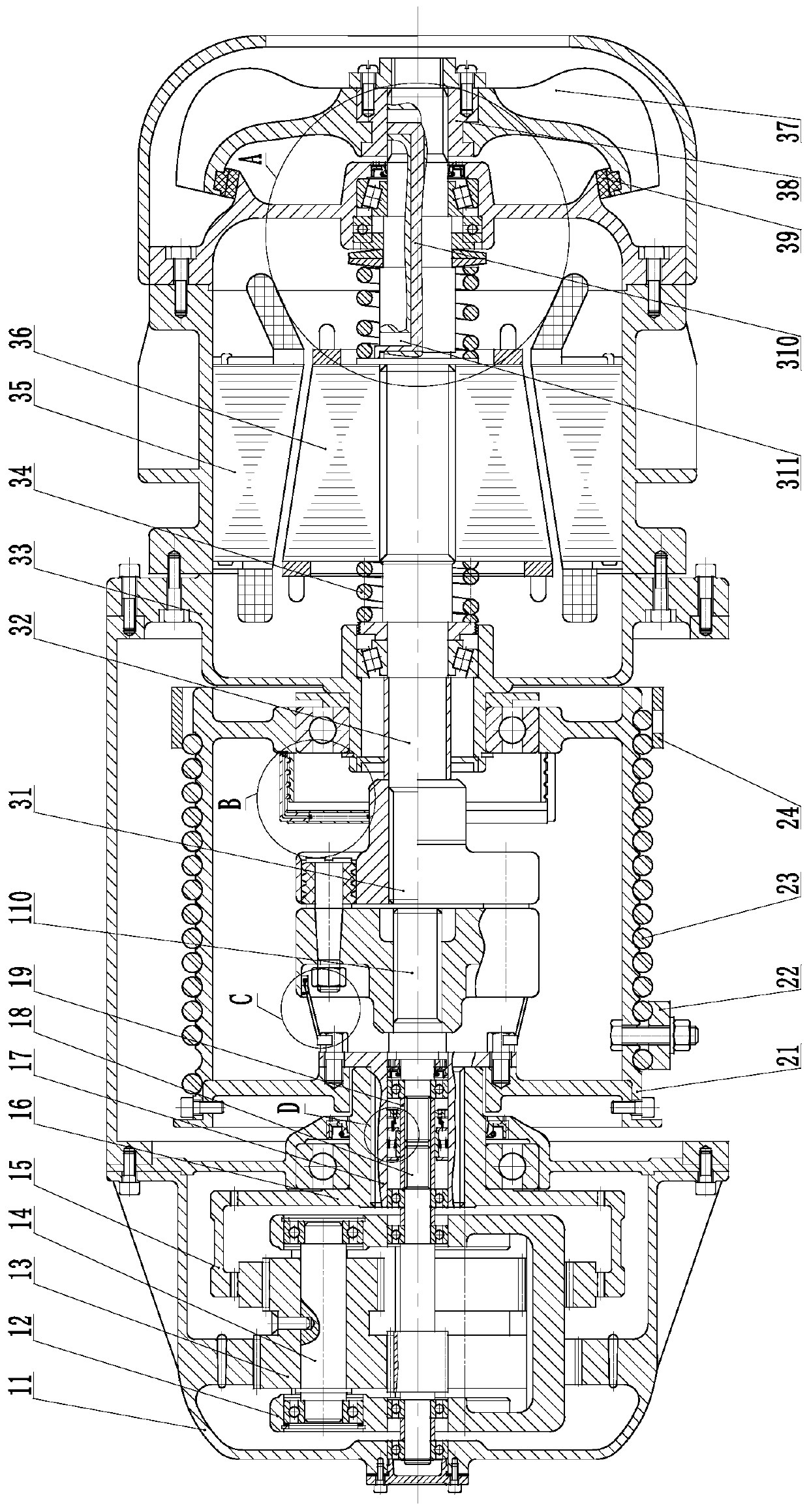

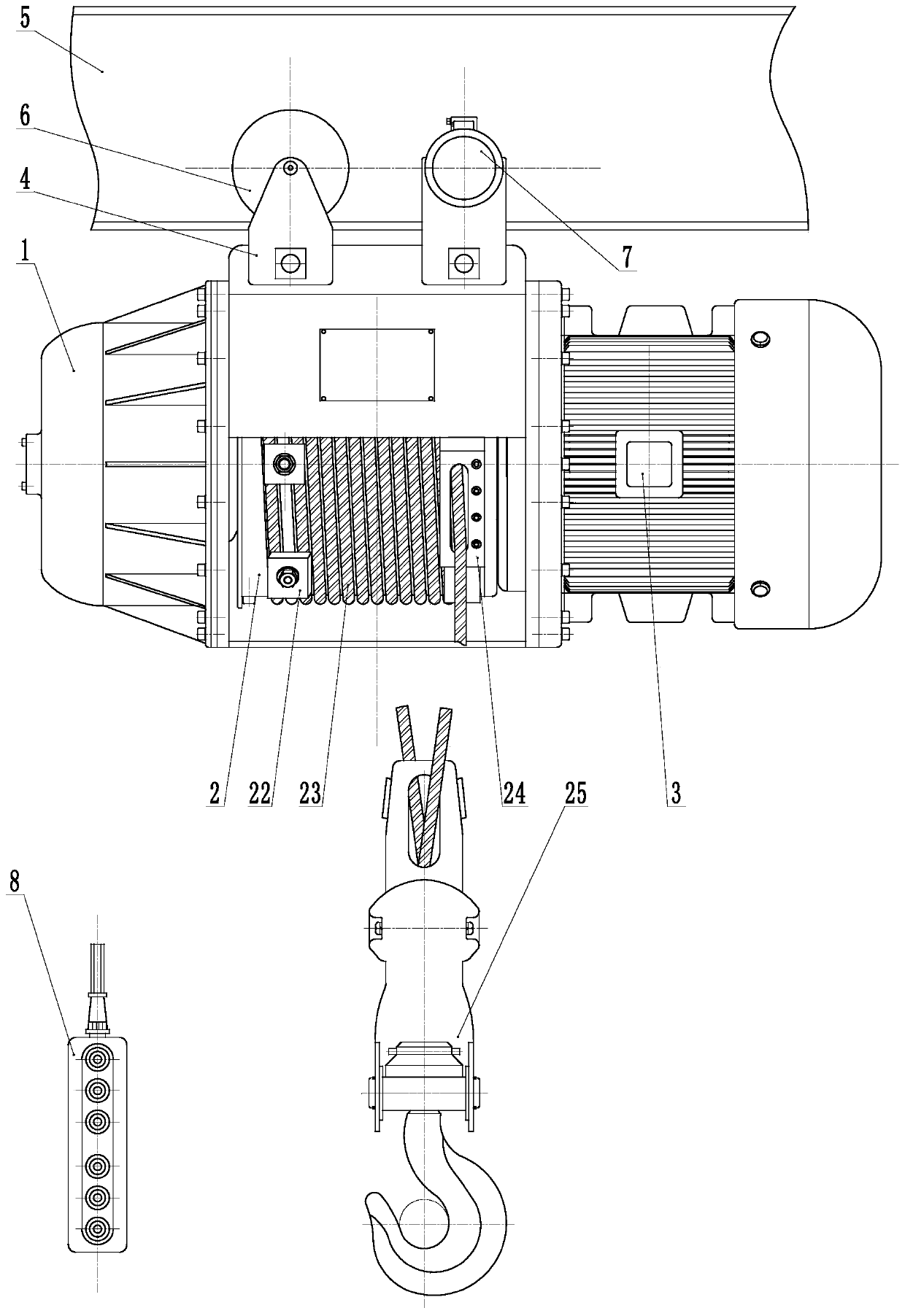

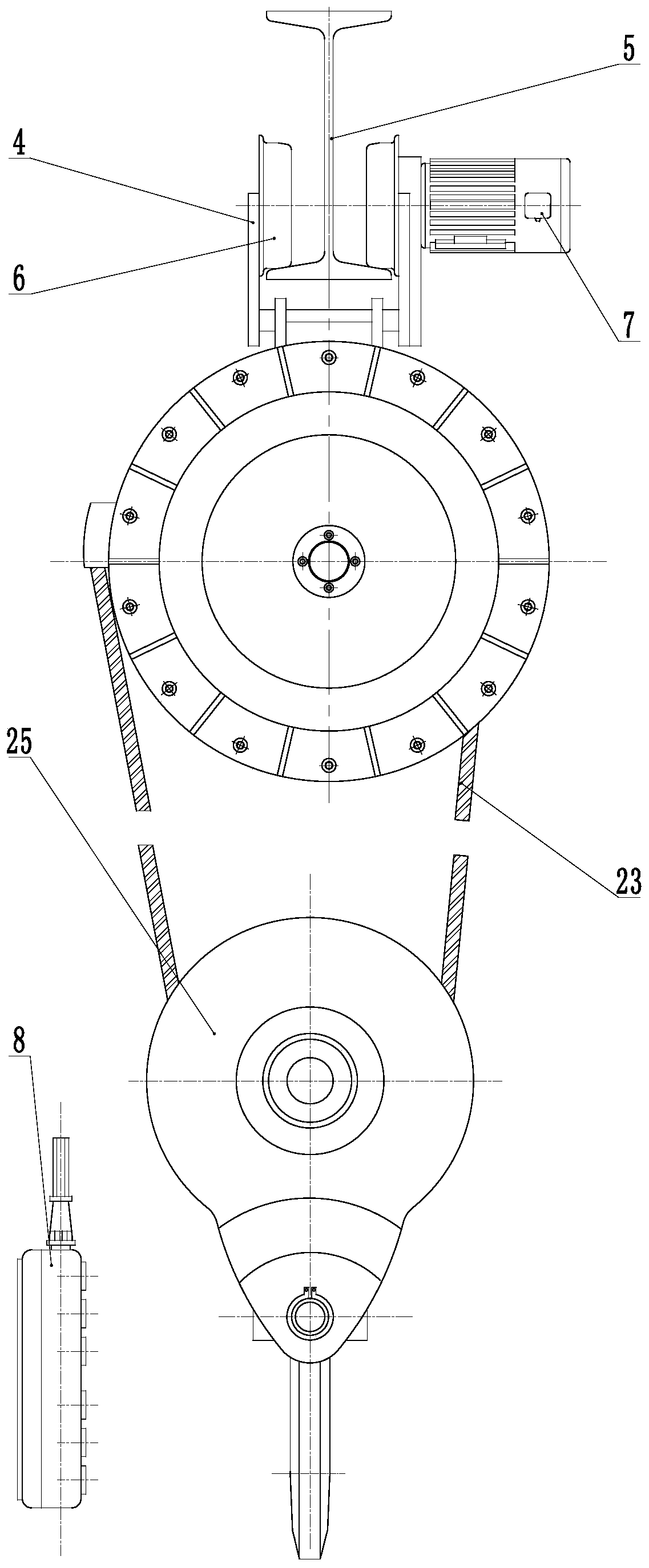

[0029] like Figure 1 to Figure 8 As shown, an electric hoist for a single-girder crane according to the present invention includes a hoisting mechanism reducer 1, a reel component 2, a hoisting mechanism motor 3, a frame 4, rails 5, wheels 6, and a running mechanism reducer 7. Remote control 8, the hoisting mechanism reducer 1 is connected to one side of the frame 4 by screws; the motor 3 of the hoisting mechanism is connected to the other side of the frame 4 by screws; Connected with the hoisting mechanism reducer 1; the hoisting mechanism reducer 1 includes a reducer box 11, a planet carrier 12, a planetary gear 13, a planetary shaft 14, a gear coupling 15, an output shaft 16, and an output flange 17. No. 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com