Ru porcelain sky-blue glaze with black stone as raw material and preparation method and firing process thereof

A technology of porcelain celadon glaze and raw materials, which is applied in the field of Ru porcelain celadon glaze and its preparation, can solve the problems of rare Ru porcelain, unstable quality, and increased cost of making porcelain, so as to reduce production costs, have strong scalability, good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

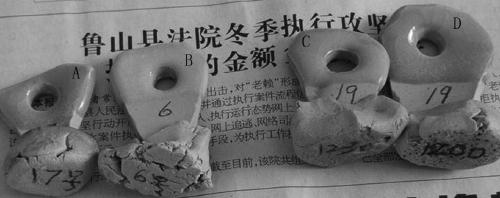

Image

Examples

Embodiment 1

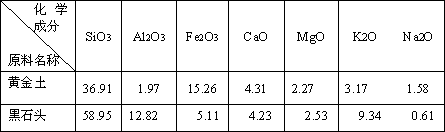

[0042]A kind of azure glaze for Ru porcelain made of black stone, made from the following raw materials: Dengfeng feldspar, Ruzhou feldspar, calcite, agate powder, black stone, ashes, and chestnut wood ash. The weight percentage of each raw material is: 38% of Dengfeng feldspar, 28% of Ruzhou feldspar, 5% of calcite, 6% of agate powder, 20% of black stone, 2% of ashes, and 1% of chestnut wood ash.

[0043] The preparation method of the chestnut wood ash is: first put the wood ash into a large basin, pour into clear water, soak for 3 hours, then stir to make it fully diluted, pass through a 50-mesh sieve to remove unburned firewood and impurities, and then pass through the 80-mesh sieve again. Filter through a mesh sieve, and after filtering, precipitate for 6 hours, then pour off the water, leaving solid matter, and obtain it after natural drying.

[0044] The preparation method of the agate powder is as follows: first calcining the natural agate, the firing temperature is 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com