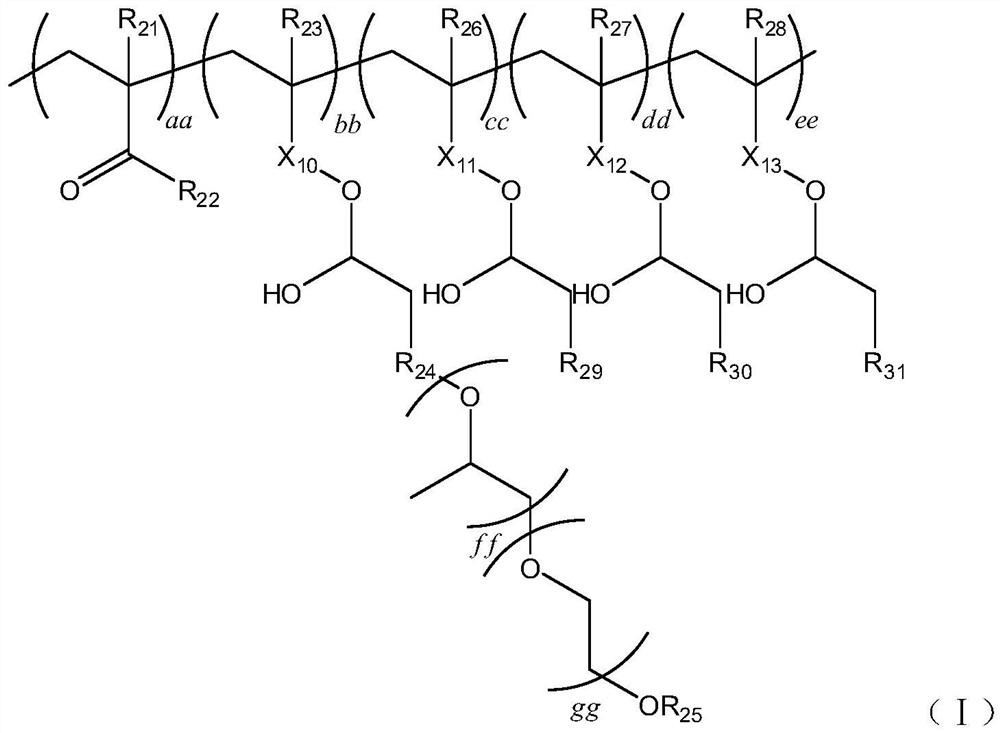

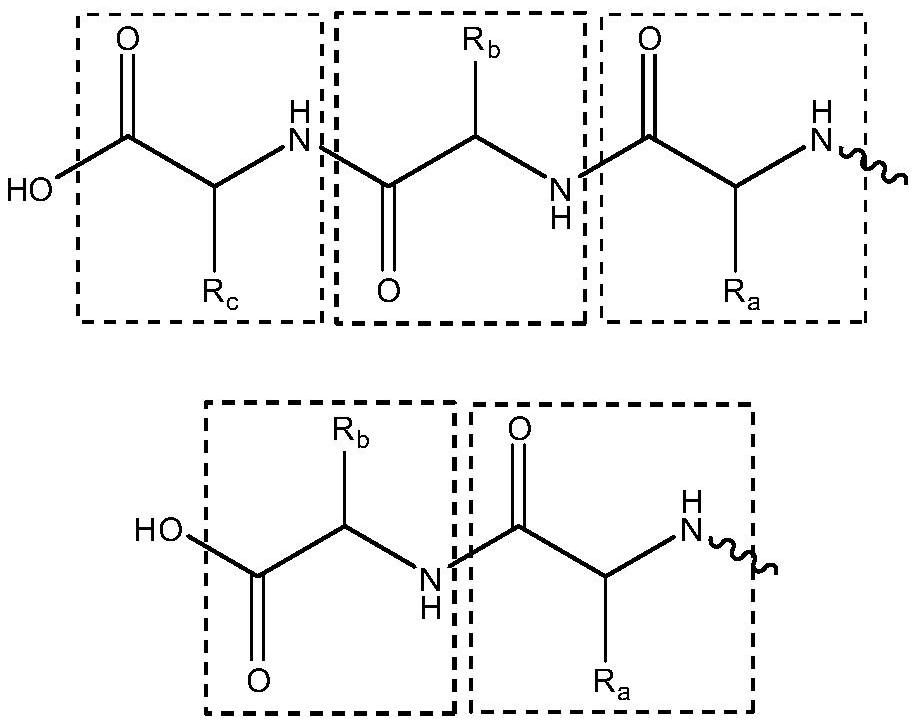

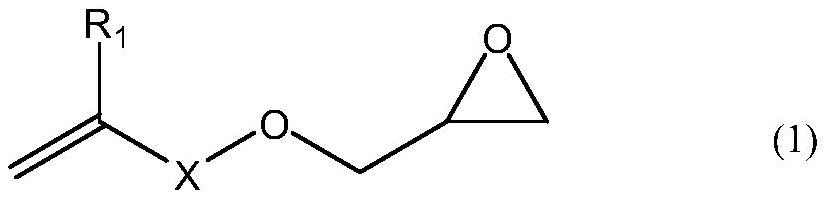

A special superplasticizer for high- and ultra-high-strength concrete and its preparation method

A technology of ultra-high-strength concrete and superplasticizers, which is applied in the field of concrete superplasticizers, and can solve problems such as weak adhesion, difficult construction, and weakened friction of ordinary water-reducing agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] (1) Add anhydrous dimethyl sulfoxide (1041.2 parts) to the reactor, adjust the temperature to 60°C, and continuously and uniformly add A1 (114.12 parts), B1 (3.13 parts), and the initiator azo A solution of diisobutyronitrile in dimethyl sulfoxide (0.2 parts of azobisisobutyronitrile dissolved in 100 parts of dimethyl sulfoxide), added dropwise for 6 hours, and continued to insulate for 6 hours after the dropwise addition, to obtain the solution of the intermediate;

[0079] (2) Adjust the temperature of the intermediate solution prepared in step (1) to 100°C, add C1 (250 parts), D1 (33.28 parts) and E1 (21.72 parts) to it at one time, and add 4.19 parts of lithium hydroxide at the same time, When starting to add the reactant and the auxiliary reaction reagent, the stirring reaction 24 obtains the mixed solution of the intermediate;

[0080] (3) Add 15 parts of anhydrous dimethyl sulfoxide to another reactor, and add phosphoric acid (14.7 parts) to it, adjust the temper...

Embodiment 2

[0082] (1) Add anhydrous dimethyl sulfoxide (266.18 parts) to the reactor, adjust the temperature to 70°C, and add A2 (128.13 parts), B2 (5.97 parts), I1 (4.96 parts) continuously and uniformly dropwise , and a solution of benzoyl peroxide (anhydrous, dehydrated by recrystallization) in anhydrous dimethyl sulfoxide (5.323 parts dissolved in 266.18 parts), added dropwise for 4h, and continued to insulate for 6h after the dropwise addition, to obtain intermediate body solution;

[0083] (2) Adjust the temperature of the intermediate solution prepared in step (1) to 150°C, add C2 (1000 parts), D2 (102.99 parts) and E2 (17.36 parts) to it at one time, and add 25.07 parts of sodium tert-butoxide at the same time , timing since the reactant and the co-reaction reagent start to add, stirring and reacting for 12h to obtain the mixed solution of the intermediate;

[0084] (3) Add 5 parts of anhydrous dimethyl sulfoxide to another reactor, and add pyrophosphoric acid (4.45 parts) and w...

Embodiment 3

[0086] (1) add anhydrous N-methylpyrrolidone (200 parts) in the reactor, adjust temperature to 40 ℃, add A3 (142.15 parts), B3 (2.34 parts), I2 (13.01 parts) to it simultaneously, add Among them, tert-butyl hydroperoxide (3.965 parts) and N-methylpyrrolidone solution of ethanethiol (0.683 parts dissolved in 110.33 parts) were evenly added dropwise respectively, added dropwise for 3 hours, and continued to keep warm for 1 hour after the addition was completed to obtain the intermediate The solution;

[0087] (2) Adjust the temperature of the intermediate solution prepared in step (1) to 40°C, add C3 (800 parts), D3 (6.06 parts) and E3 (6.15 parts) to it at one time, and add 19.35 parts of lithium hydroxide at the same time, Timing since the reactant and the auxiliary reaction reagents start to add, stirring the reaction for 24h to obtain the mixed solution of the intermediate;

[0088] (3) Add 100 parts of anhydrous N-methylpyrrolidone to another reactor, and add phosphorus pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com