Coating tooling and installation method for elongated reflectors

A mirror and strip-shaped technology, applied in the field of fixtures, can solve the problems of narrow installation environment of the coating cavity, and achieve the effect of eliminating the risk of bumping, reducing the tolerance size, and improving the control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

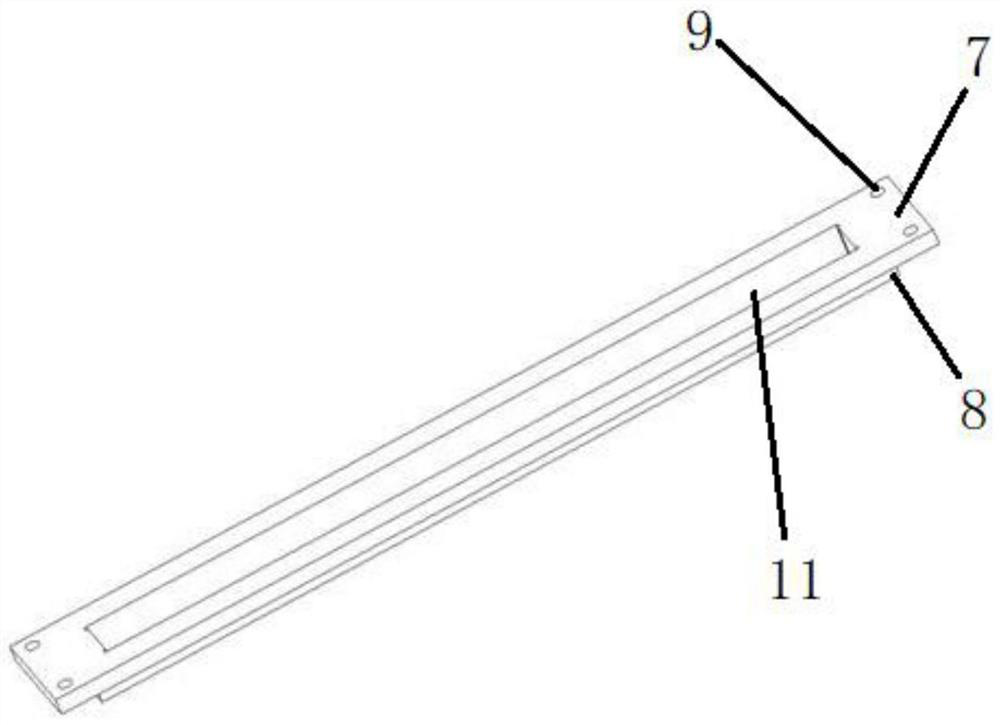

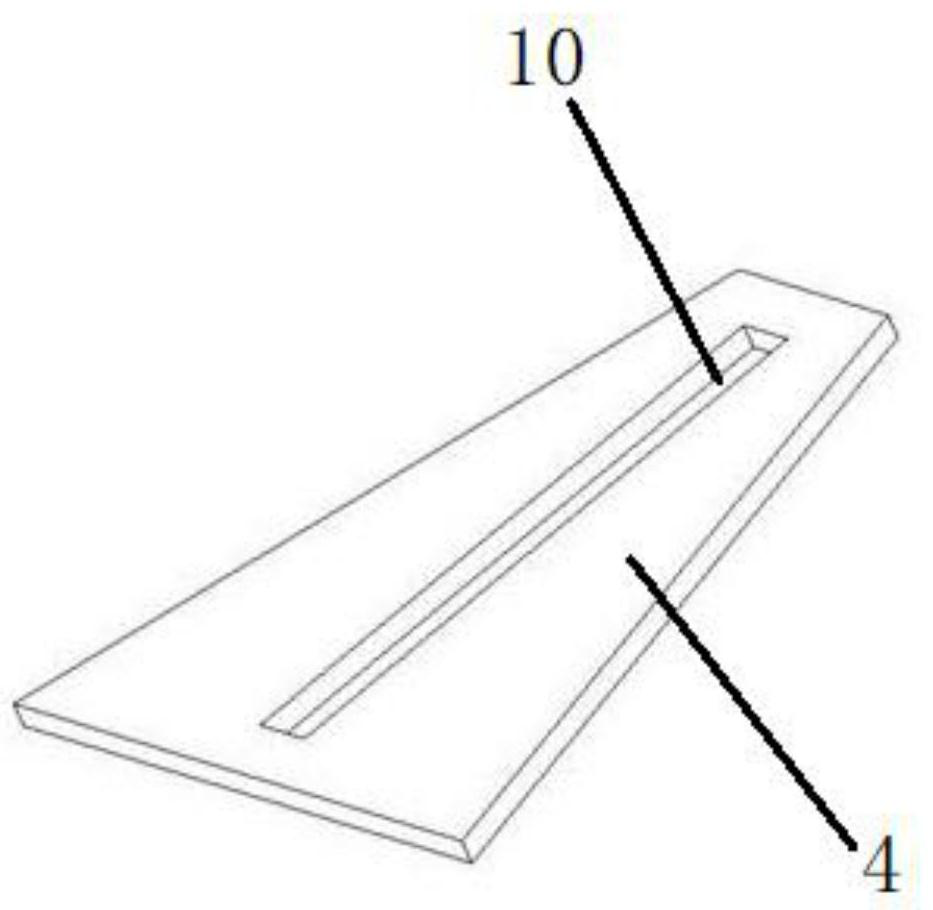

[0031] A kind of coating frock for elongated reflector, comprising a fixed supporting plate 4 such as image 3 As shown, two movable pallets 1, 2 are as figure 1 Shown and 4 positioning rods 3 as figure 2 shown. The fixed supporting plate 4 can be fixed on the umbrella stand of the coating machine, and a first rectangular groove 10 is opened in the center. The movable pallets 1 and 2 include a panel 7 and a bottom plate 8 that are bonded together up and down. The bottom plate 8 is equal in width, length and height to the first rectangular groove 10 , and can be embedded in the first rectangular groove 10 . The center of the movable pallet 1 and 2 is provided with a second rectangular groove 11, the second rectangular groove 11 is equal in width and length to the strip reflector, and the height of the strip reflector is greater than twice the second rectangular gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com