Online monitoring method and system of air valve

A technology for air valves and maintenance valves, which is applied in the direction of valve operation/release devices, valve details, valve devices, etc. It can solve the problems of low reliability, inability to be timely and effective, and close the water inlet of air valves to achieve intelligent, Avoid the effects of water hammer in the pipe network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following specific examples illustrate the present invention in further detail.

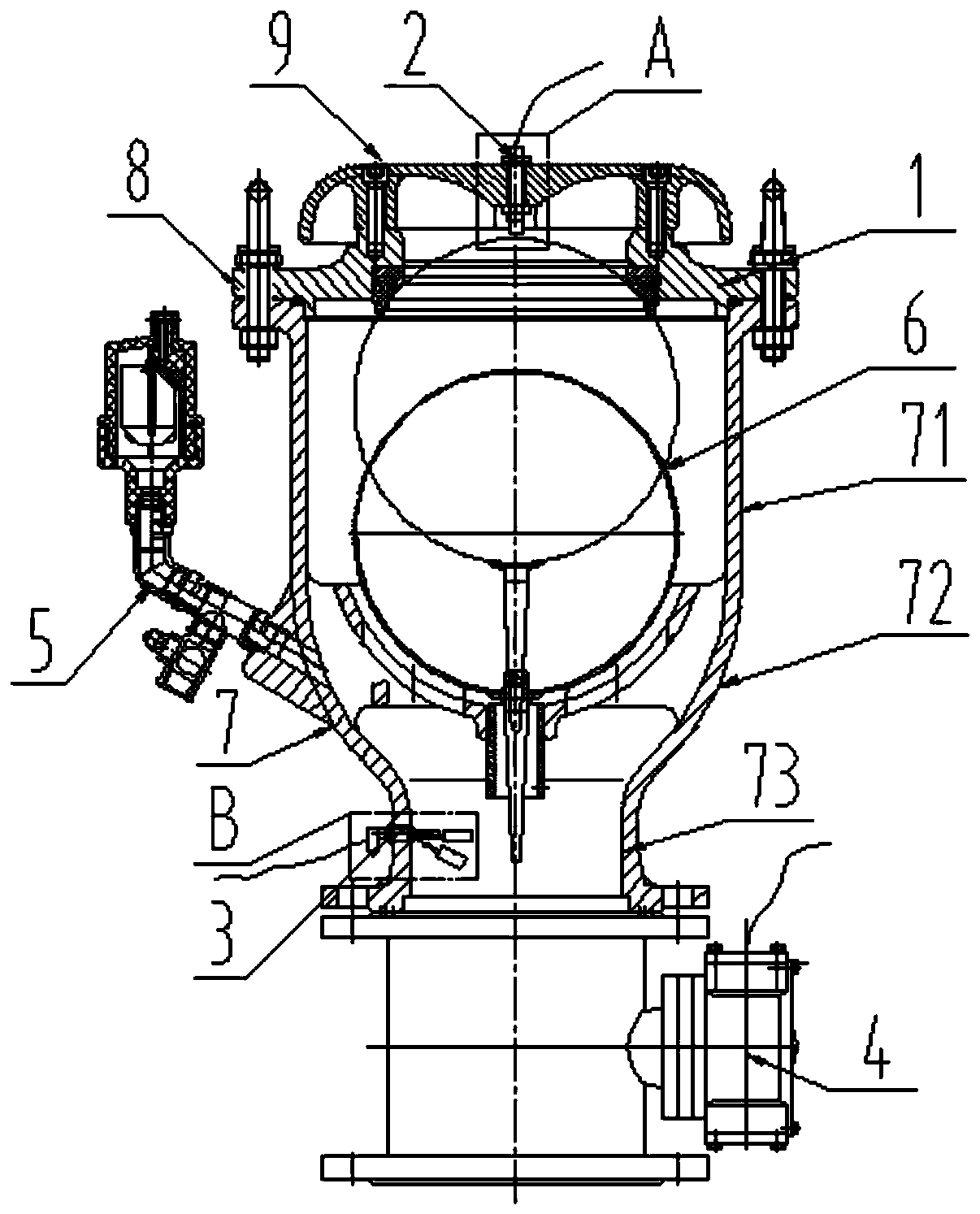

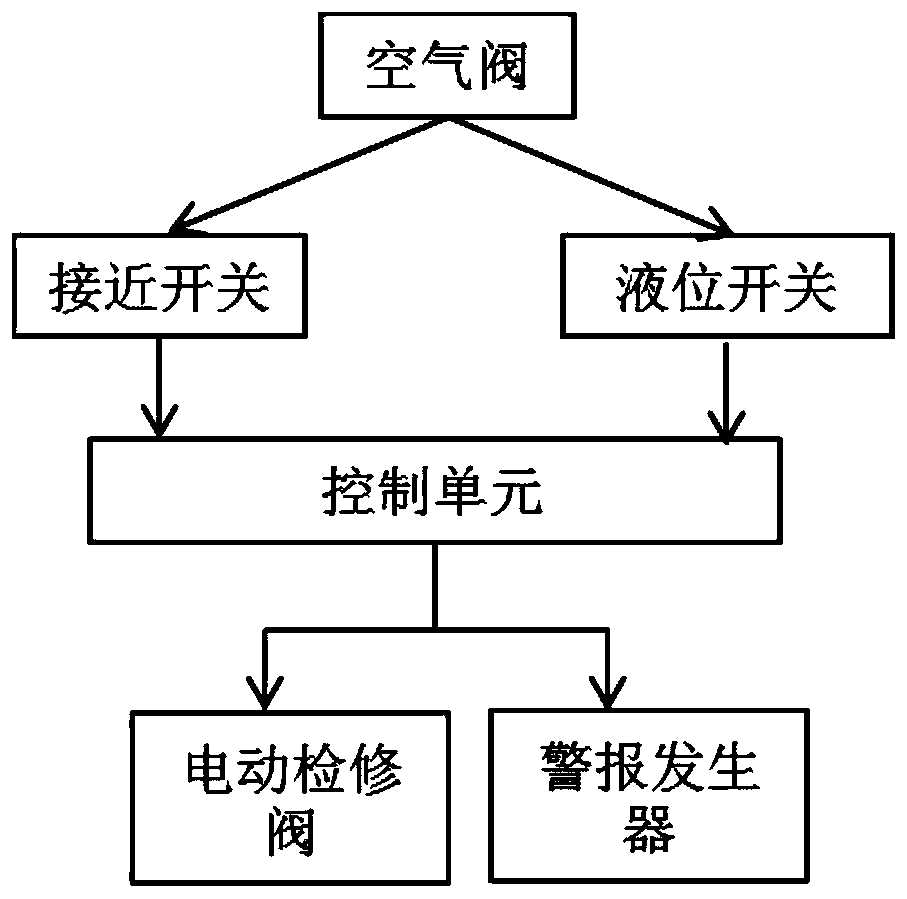

[0036] Such as Figure 1-2 As shown, the present invention provides a monitoring method for an air valve, the steps are:

[0037] a. Set the electric maintenance valve 4 at the water inlet of the air valve 1, and open it under normal conditions;

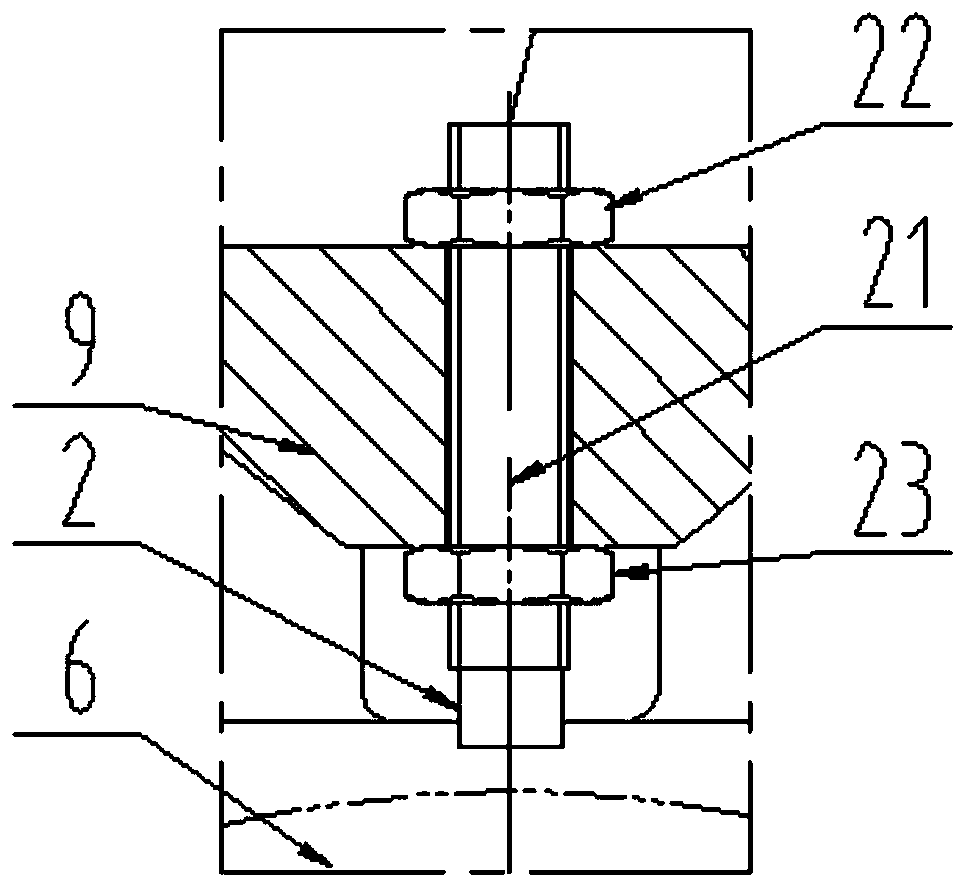

[0038] Proximity switch 2 is set on the top of air valve 1. Use proximity switch 2 to monitor the float position in real time. Proximity switch 2 is located where the float is sealed with the large exhaust port (here is the highest position that the float can reach in the valve) Signal A is sent when it is lower than the seal with the large exhaust port, and signal B is sent;

[0039] The air valve 1 or the electric maintenance valve 4 is equipped with a liquid level switch 3, the liquid level switch 3 is a magnetic floating liquid level sensor, and the liquid level switch 3 is used to monitor the water level in the air valve 1 in real time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com