Gas water heater control method and gas water heater

A technology of gas water heater and control method, which is applied in the directions of fluid heaters, lighting and heating equipment, etc., can solve problems such as failure to reach, water pump consumes too much power, and cannot automatically exit the preheating mode, and achieves sufficient preheating, reducing Power consumption, the effect of avoiding misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

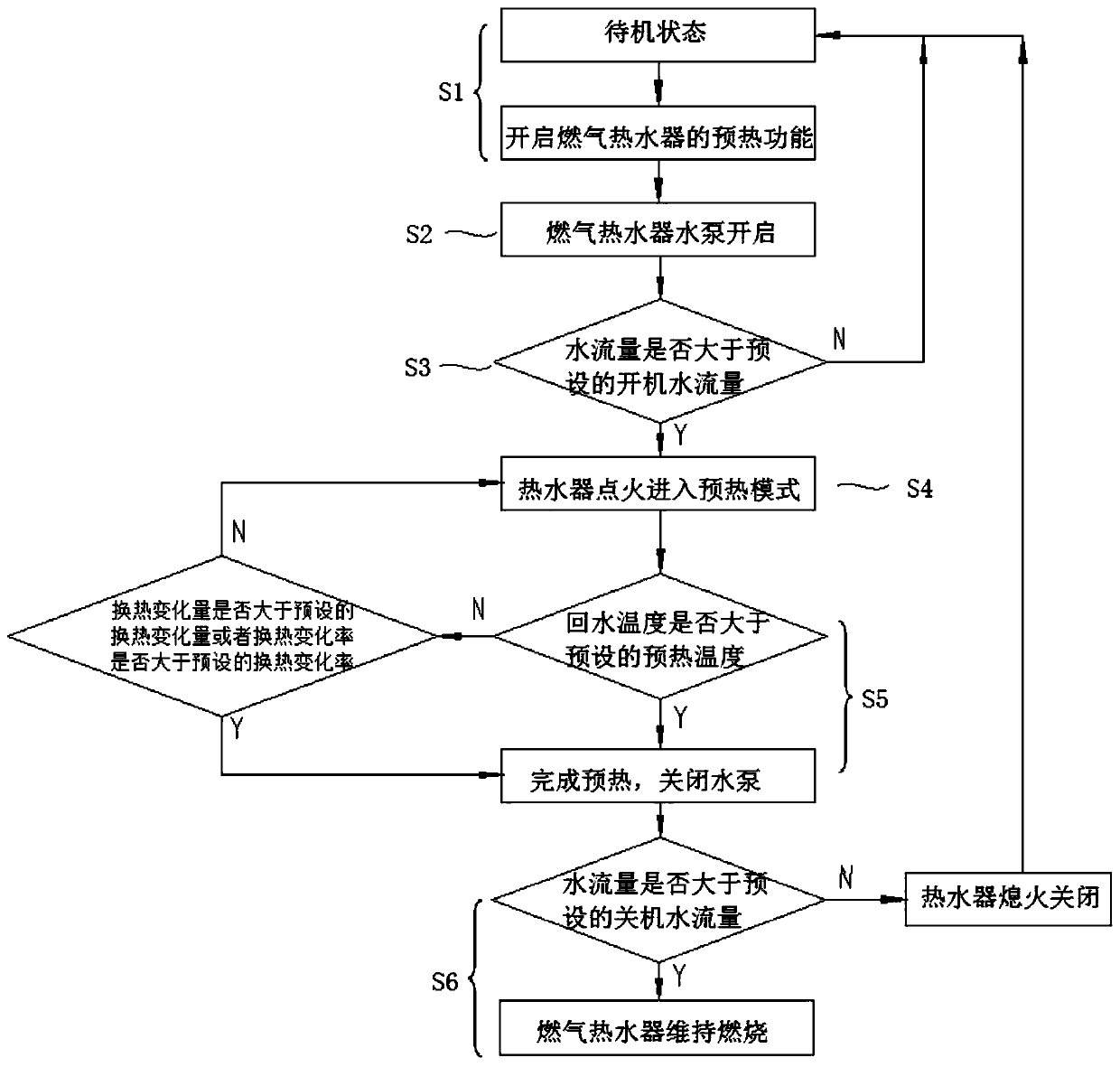

[0040] Embodiment 1 of the present invention provides a gas water heater control method, such as figure 1 As shown, the specific steps are as follows:

[0041] S1, turn on the preheating function of the gas water heater in the standby state;

[0042] S2, the water pump of the gas water heater is turned on;

[0043] S3, detecting the water flow rate on the main waterway of the gas water heater, and when the water flow rate is greater than the preset starting water flow rate, enter S4; otherwise, the gas water heater remains in the standby state;

[0044] S4, the gas water heater ignites and enters the preheating mode;

[0045] S5, detecting the return water temperature of the gas water heater, when the return water temperature is greater than the preset preheating temperature, the preheating is completed, and the water pump is turned off; otherwise, the working state of the gas water heater is controlled by the change of the heat exchange rate of the gas water heater;

[004...

Embodiment 2

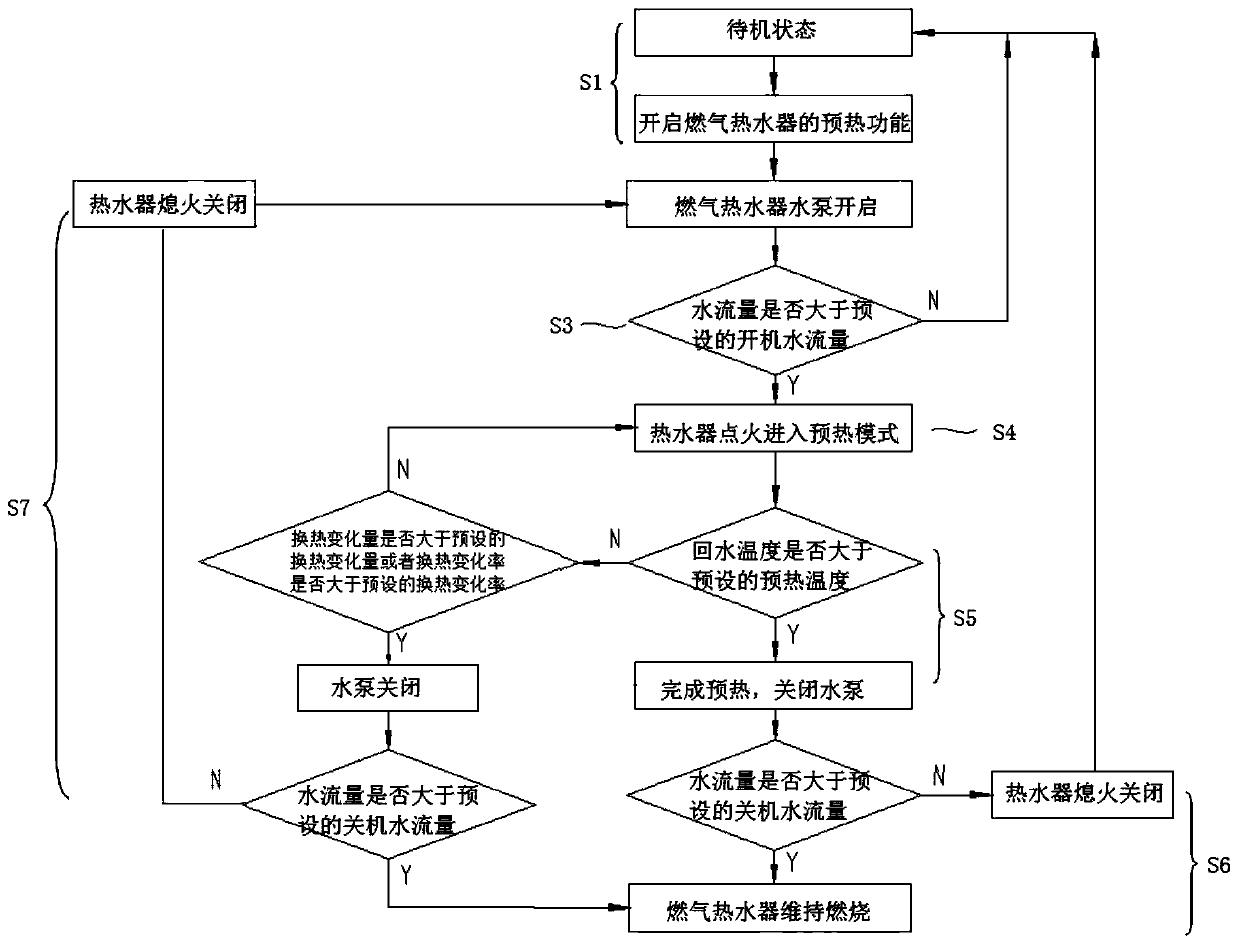

[0065] Embodiment 2 of the present invention provides a gas water heater control method, such as figure 2 Shown, it further comprises on the basis of embodiment 1:

[0066] S7, when the heat transfer change amount of the gas water heater is greater than the preset heat transfer change amount, or the heat transfer change rate of the gas water heater is greater than the preset heat transfer change rate, the water pump is turned off;

[0067] At this time, it is judged whether the water flow on the main waterway of the gas water heater is greater than the preset shutdown water flow, and if so, the gas water heater keeps burning; otherwise, the gas water heater is turned off and returns to S2.

[0068] In this way, after turning off the water pump, when the measured water flow rate is less than the shut-off water flow rate, it means that the hot water faucet has not been turned on, which is a malfunction. Briefly turn on the hot water to interrupt the cycle preheating process to...

Embodiment 3

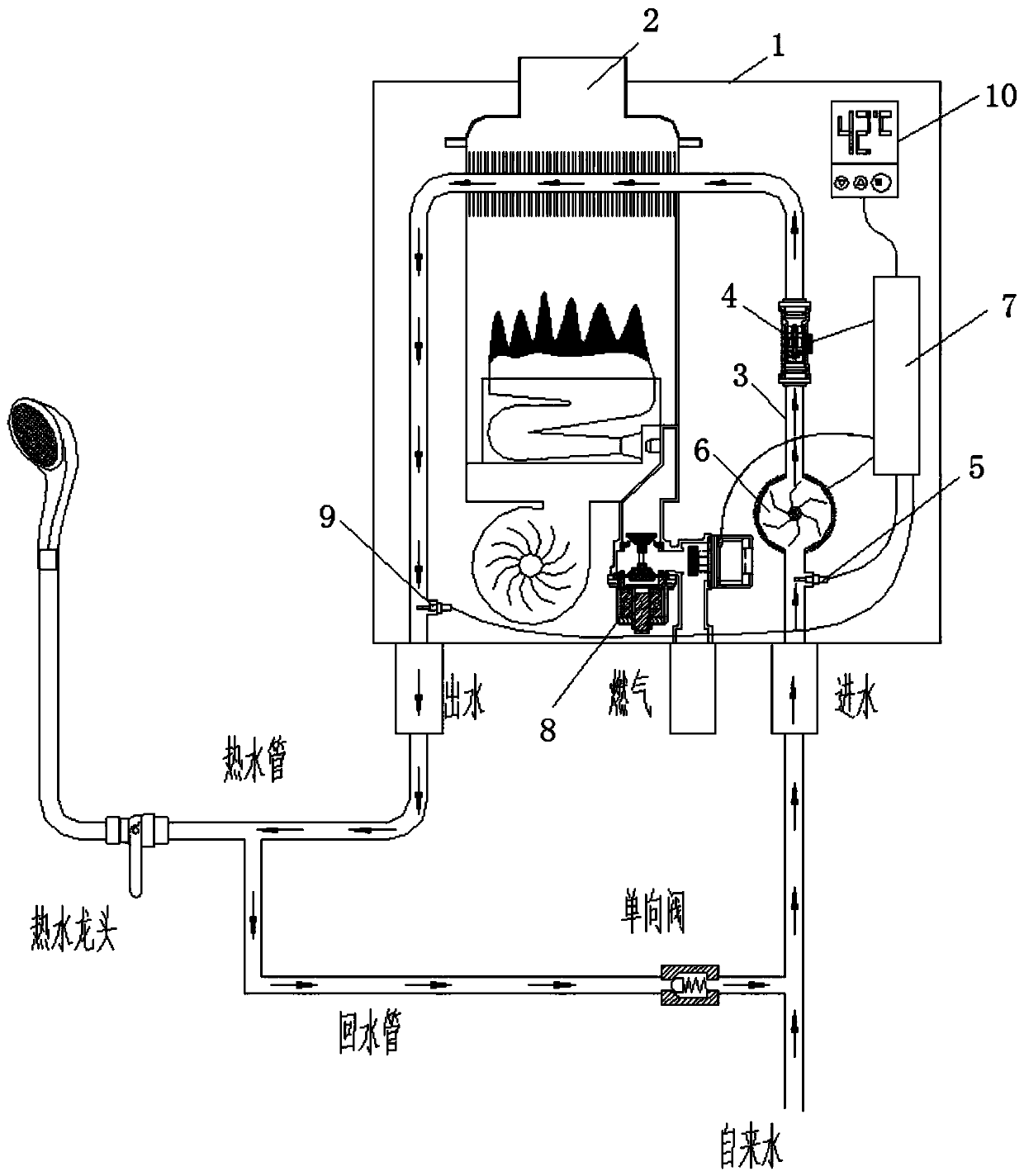

[0070] Embodiment 3 of the present invention provides a gas water heater, such as Figure 3-4 Shown:

[0071] It includes a water heater body 1, a heat exchanger 2, a water flow pipeline 3, a water flow sensing unit 4, an inlet water temperature detection unit 5, a water pump 6, a controller 7, a gas control valve 8, and an outlet water temperature detection unit 9, wherein:

[0072] The heat exchanger 2 is arranged in the water heater body 1, the water flow pipeline 3 passes through the heat exchanger 2, the water flow induction unit 4 and the water pump 6 are both arranged on the water flow pipeline 3, and the inlet water temperature detection unit 5 and the water outlet temperature detection unit 9 are respectively arranged at the water inlet end and the water outlet end of the water heater body 1, and the water flow sensing unit 4, the water pump 6, the water inlet temperature detection unit 5, the gas control valve 8 and the water outlet temperature detection unit 9 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com