Vertical track board shape detecting device and method

A detection device and track plate technology, which is applied to measurement devices, active optical measurement devices, optical devices, etc., can solve the problems of artificial influence of precision, low detection efficiency of the finished track plate shape, and low degree of detection automation, and achieve detection results. The effect of fast output and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

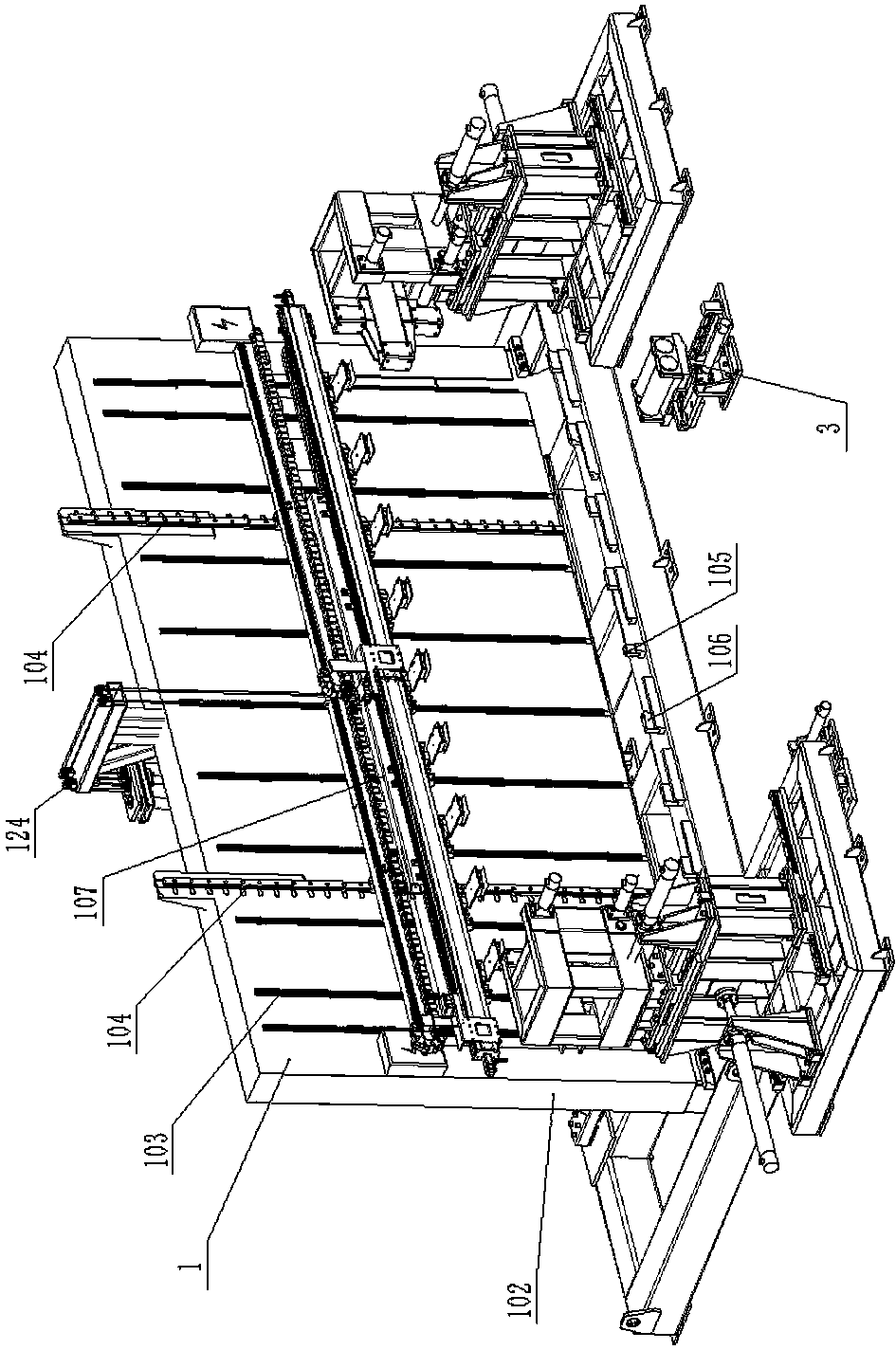

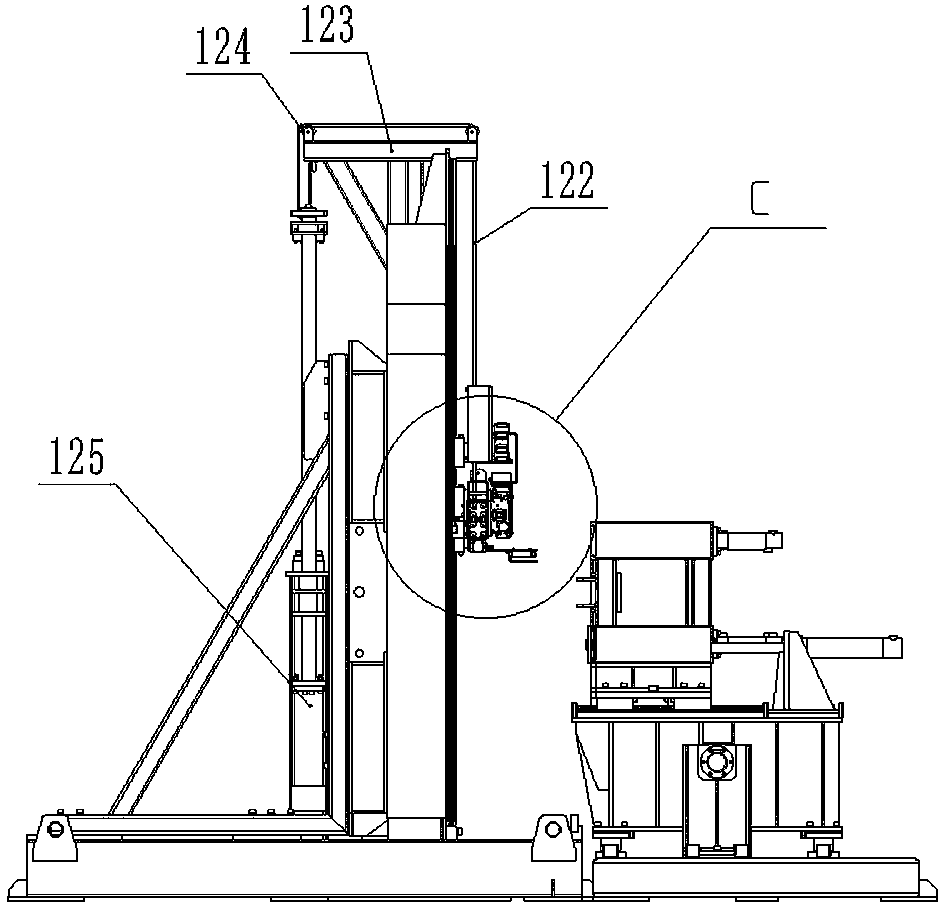

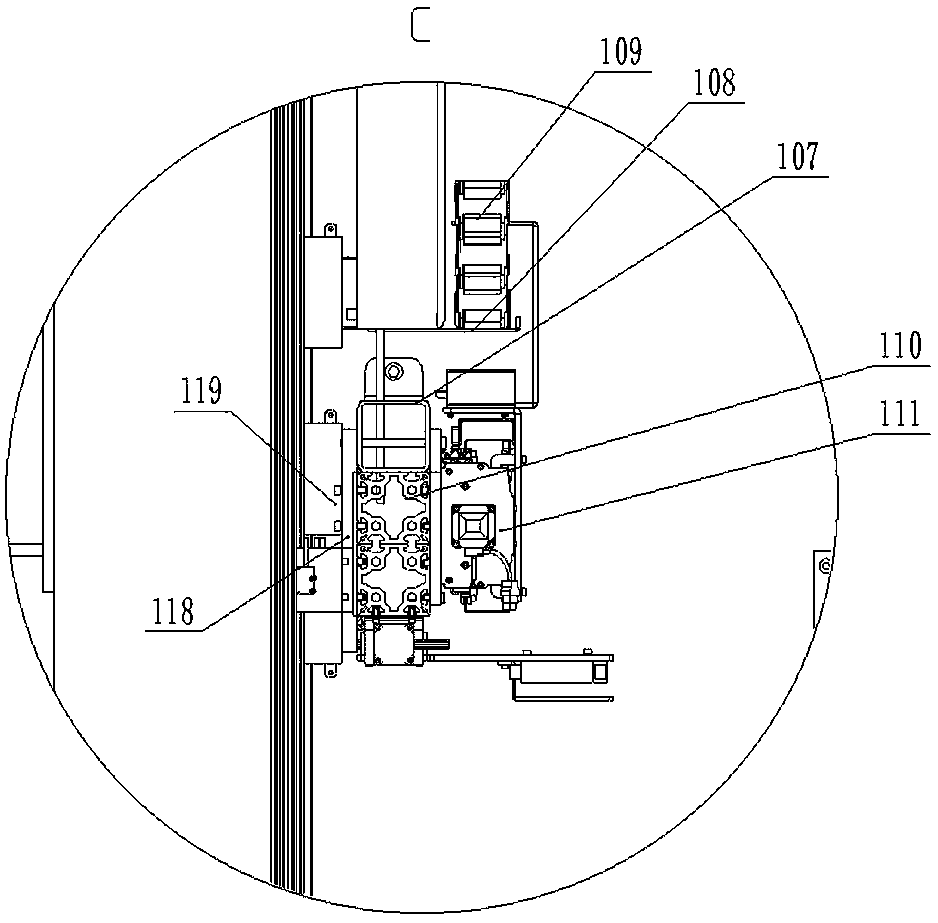

[0023] Such as figure 1 , a vertical track slab appearance detection device and method, including a detection device 1, a track slab adjustment device 2, and a track slab auxiliary adjustment device 3. The detection device 1 includes: a base 101 set on the ground, an upright vertical base 102 is fixedly arranged on the base 101, and a plurality of vertical lifting magnetic grid sensor magnetic strips 103 are arranged at intervals on the working surface on one side of the vertical base 102, Two vertical slide rails 104 are provided on the center line of the working surface on one side of the vertical base 102 symmetrically (parallel with the magnetic strip 103 of the magnetic grid sensor), and on the end surface of the base 101 adjacent to the working surface on the side of the vertical base 102 Reference blocks A105 and / or several reference blocks B106 corresponding to the magnetic strips 103 of the lifting magnetic grid sensor are evenly spaced; preferably, the reference bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com