A kind of aviation aluminum-based stainless steel pleated filter element cleaning and detection method

A technology of folding filter element and detection method, applied in the field of aviation maintenance, can solve the problems of affecting the accuracy of engine test results, affecting the quality of oil, and high damage rate, and achieving the effect of shortening cleaning time, increasing cleaning frequency and reducing contact time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

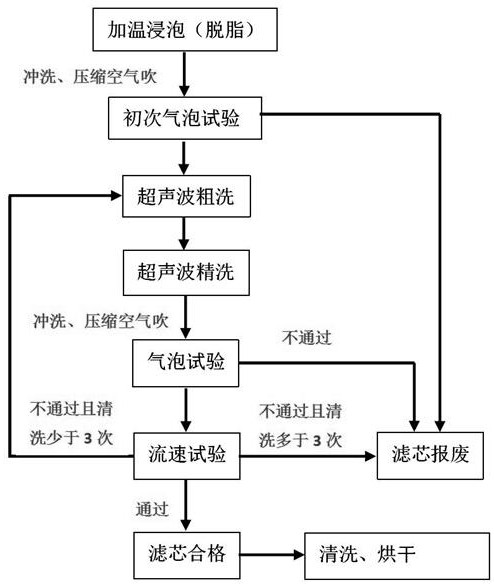

[0027] As shown in Figure 1, the specific embodiment of the present invention mainly includes the following steps:

[0028]Soak the filter element to be cleaned with RP-3 aviation kerosene for 2 hours. During the soaking process, take it out every 40 minutes and blow it back and forth with low-pressure compressed air. The soaking temperature is 60-70°C. During the long-term use of the filter element, impurities such as grease have adhered tightly to the surface of the filter element, causing the filter element to be blocked, and grease is easily soluble in organic solutions, so RP-3 aviation kerosene is used to soak the filter element; After soaking in kerosene, it gradually dissolves or does not adhere so tightly to the surface of the filter element. After soaking for half an hour, use low-pressure compressed air to carry out forward and reverse blowing on the filter element to achieve preliminary removal of the adhesion on the surface of the filter element, or reduce The adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com