Interference and kinematic constrained five-axis machining tool axial linear optimization method

An optimization method, kinematics technology, applied in the direction of instruments, digital control, control/regulation systems, etc., can solve problems such as limiting the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

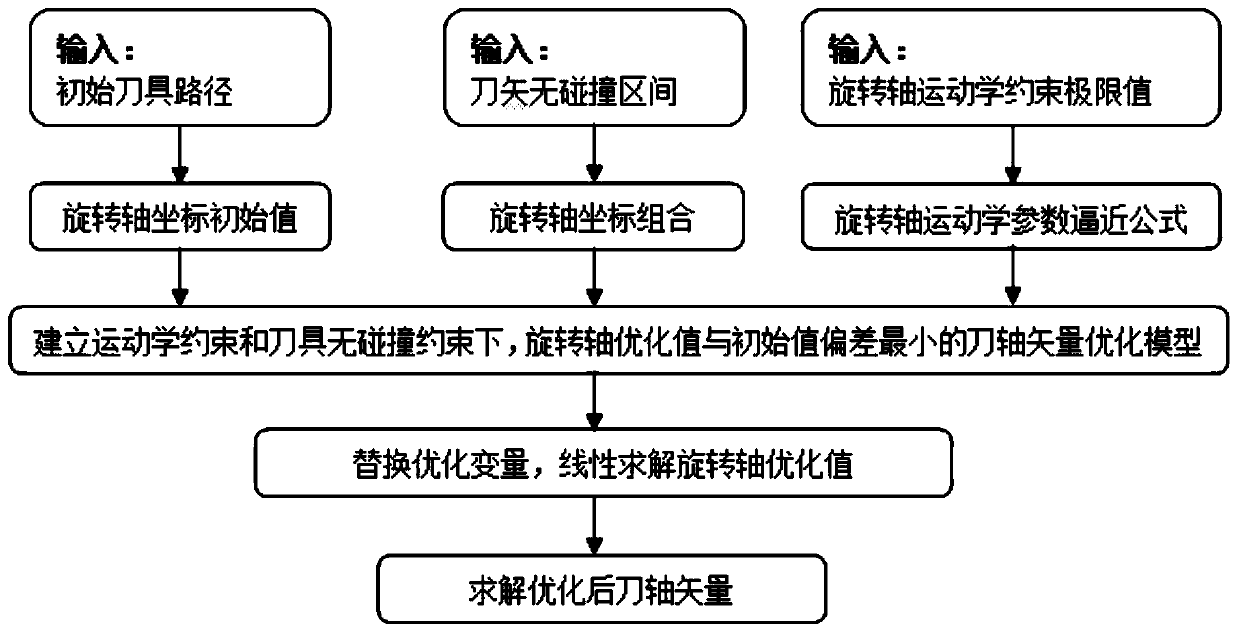

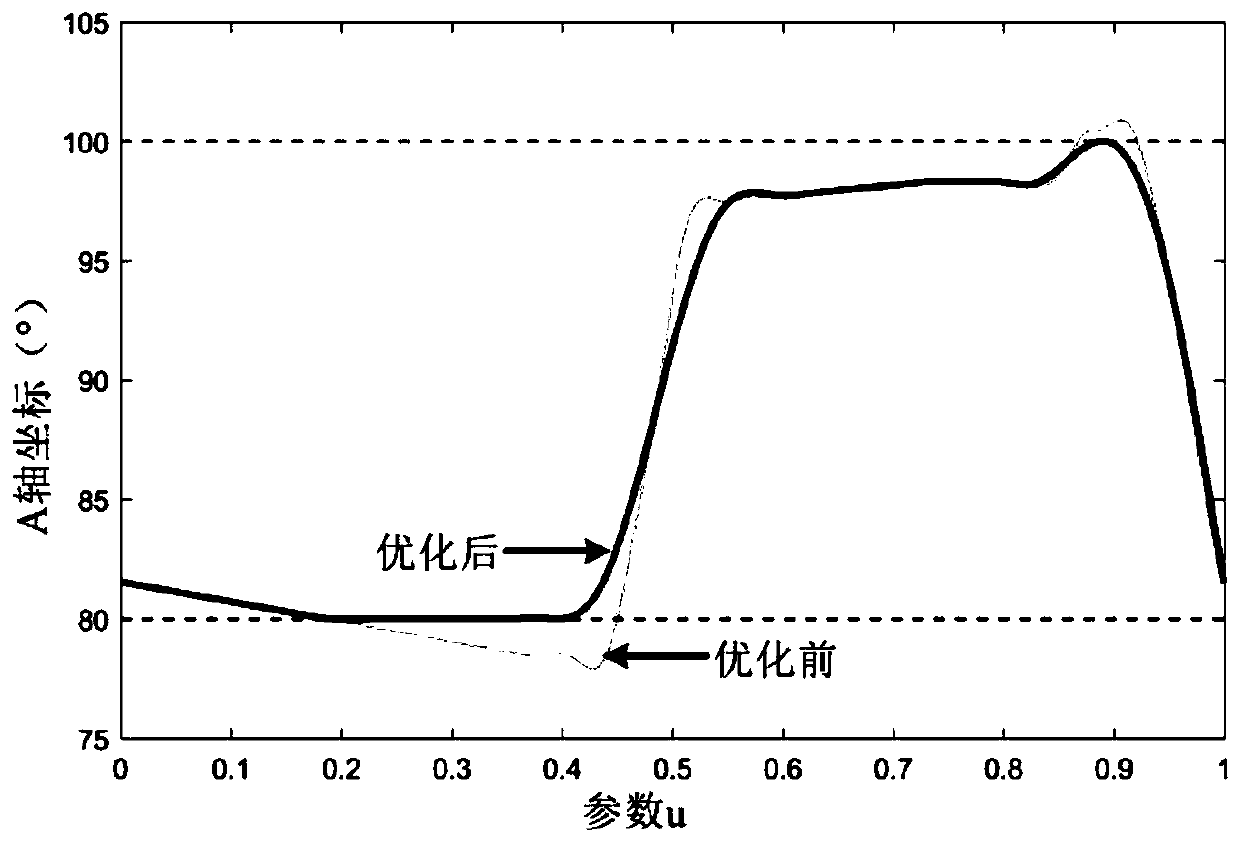

[0058] The flow chart of a tool axis vector adjustment method considering the driving ability of each rotary axis in five-axis NC machining is as follows: figure 1 shown. First, transform the feasible space of the tool axis vector and the initial tool axis vector into the expression of the rotation axis in the machine tool coordinate system; The angular velocity, angular acceleration and angular jerk constraints of the axis are established, and the linear optimization model of the tool axis vector is established, and the optimized tool path is finally solved. .

[0059] Without loss of generality, taking the A-C double turntable machine tool as an example, the specific implementation process of the present invention will be described in detail in conjunction with the accompanying drawings and implementati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com