HoloLens-based intelligent assembly production line simulation method

A technology of assembly line, simulation method, applied in the direction of total factory control, instrumentation, total factory control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] A HoloLens-based intelligent assembly production line simulation method proposed by the present invention is described in detail in conjunction with the accompanying drawings as follows:

[0056] The method proposed by the present invention, based on the HoloLens head-mounted display device, is used for the assembly simulation of the discrete mixed-flow assembly line. There is a clear correspondence between the assembly process and the equipment in the discrete mixed-flow assembly line, and there is no priority difference between different products. Use this as an assembly line feature. The specific process of this method is as follows:

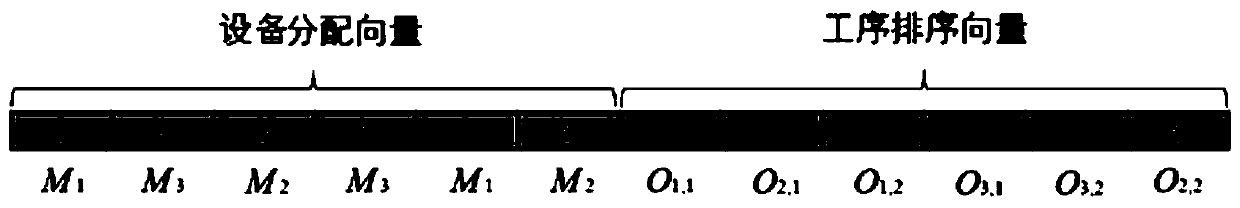

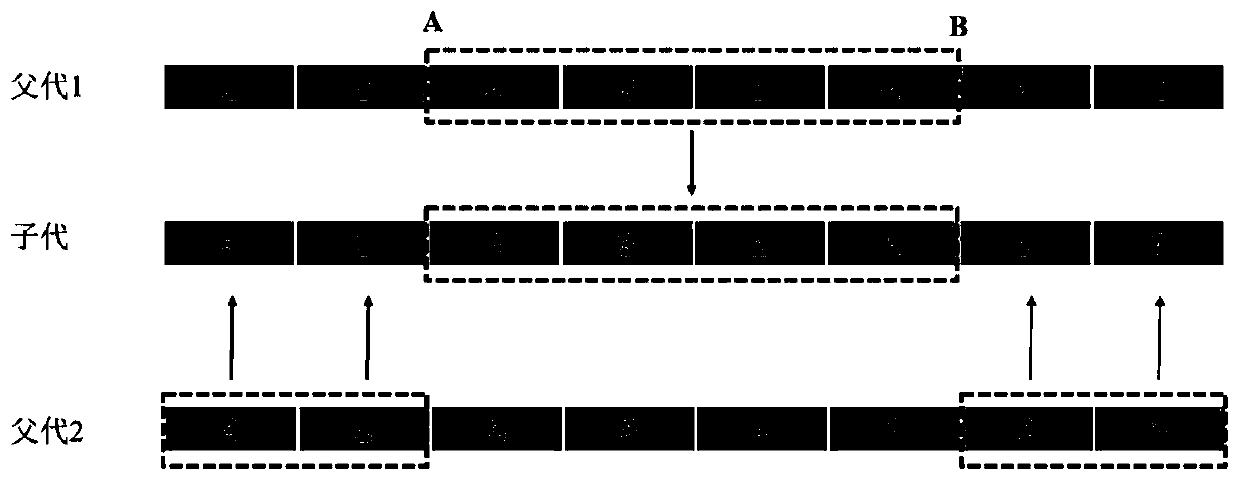

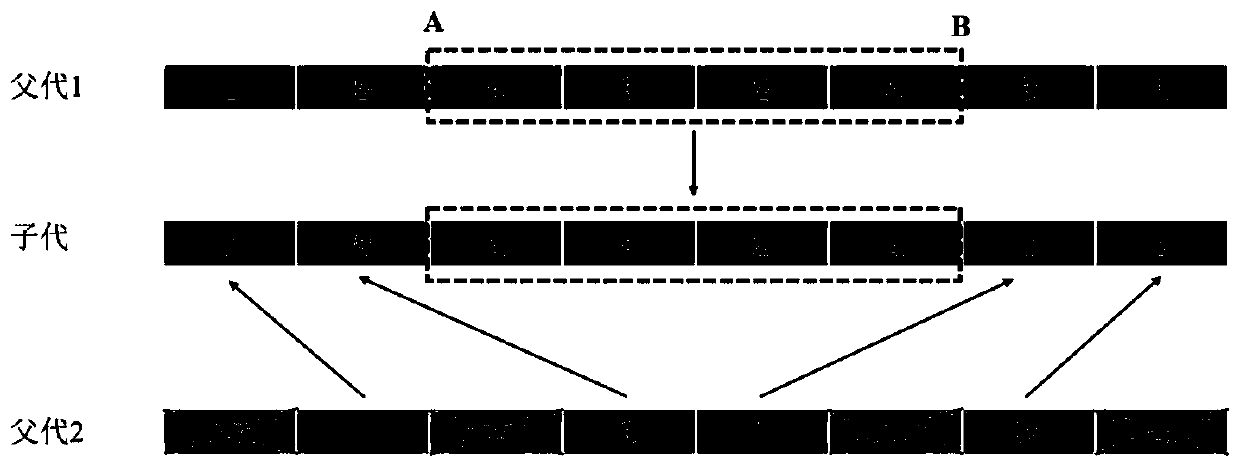

[0057] 1) Mathematical modeling and simulation is carried out on the production scheduling of the assembly line. Through this step, the actual assembly process is abstracted into a mathematical problem. The specific steps are as follows:

[0058] 1-1) Determine the constraints

[0059] According to the characteristics of the assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com