Raw material extraction system for processing of body wash

An extraction system and shower gel technology, applied in manufacturing tools, presses, grain processing, etc., can solve the problems of incomplete juice collection, clogging of sieve plates, affecting juice filtration and collection, etc., and achieve the effect of avoiding incomplete juice collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

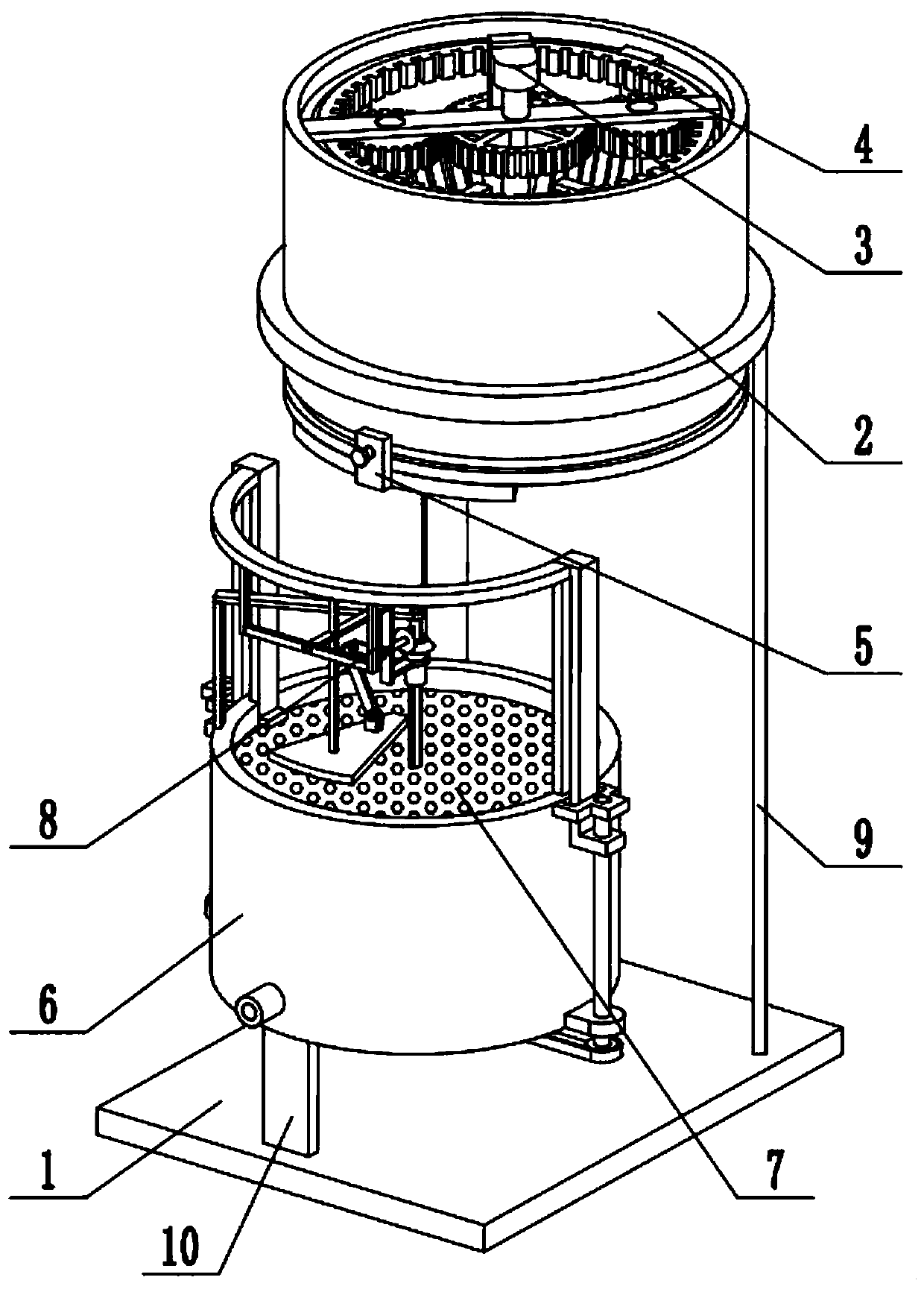

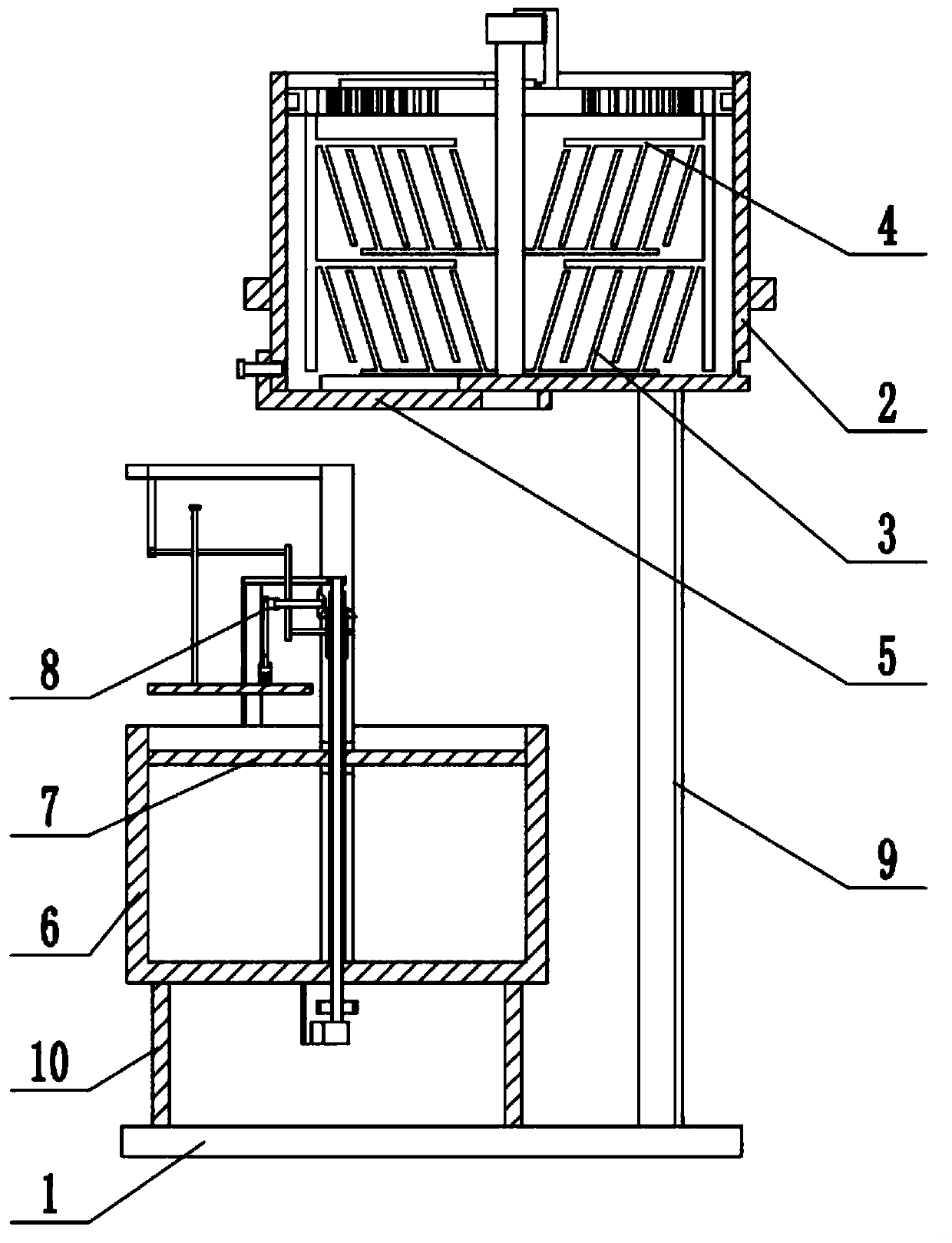

[0030] Combine below Figure 1-12 Describe this embodiment, a raw material extraction system for shower gel processing, including a base 1, a crushing cylinder 2, a central drive assembly 3, a crushing driven assembly 4, a movable bottom cover 5, an extrusion cylinder assembly 6, and a movable sieve plate assembly 7. Squeeze drive mechanism 8, support plate 9 and support legs 10. The crushing cylinder 2 is fixedly connected to the base 1 through two support plates 9, and the central drive assembly 3 is fixedly connected to the upper end of the crushing cylinder 2. The moving assembly 4 is slidingly fitted and connected in the crushing cylinder 2, the crushing driven assembly 4 is meshed with the central driving assembly 3, and the movable bottom cover plate 5 is arranged at the lower end of the crushing cylinder 2, and the extrusion cylinder assembly 6 passes through two supporting legs 10 Fixedly connected to the base 1, the rear end of the extrusion cylinder assembly 6 is lo...

specific Embodiment approach 2

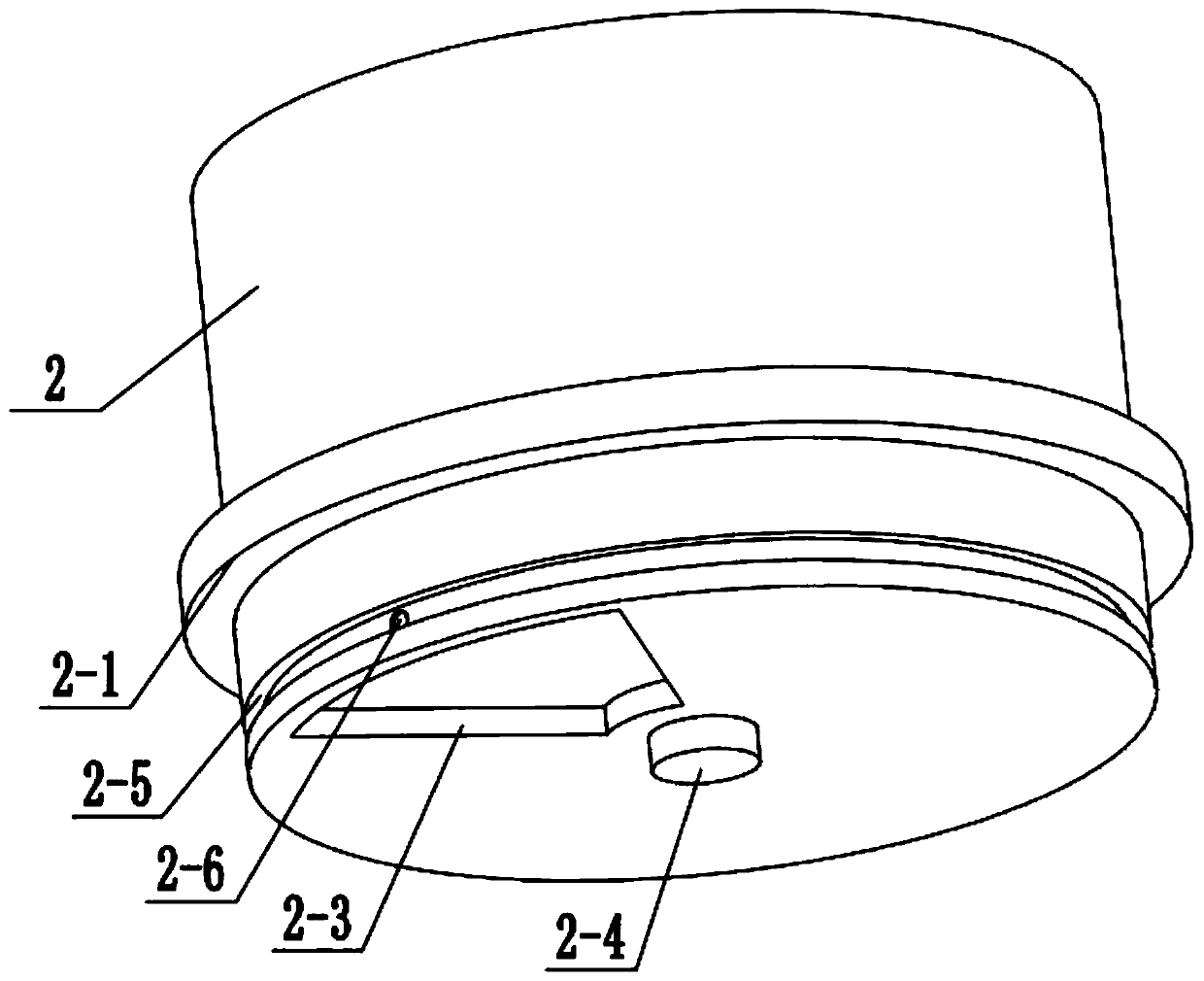

[0032] Combine below Figure 1-12 To illustrate this embodiment, the crushing cylinder 2 is provided with a fixed ring 2-1, a guide ring 2-2, a fan-shaped discharge opening 2-3, a short shaft 2-4, an annular groove 2-5 and a threaded hole 2 -6; the outer end of the crushing tube 2 is fixedly connected to the fixed ring 2-1, the fixed ring 2-1 is fixedly connected to the base 1 through two support plates 9, and the upper end of the inner wall of the crushing tube 2 is fixedly connected to the guide ring 2-2, The bottom surface of the crushing cylinder 2 is provided with a fan-shaped discharge port 2-3, the center of the bottom surface of the crushing cylinder 2 is fixedly connected with the short shaft 2-4, the lower end of the outer wall of the crushing cylinder 2 is provided with an annular groove 2-5, and the threaded hole 2-6 is provided In the annular groove 2-5; the movable bottom cover plate 5 is rotatably connected to the short shaft 2-4, and the broken driven assembly ...

specific Embodiment approach 3

[0034] Combine below Figure 1-12 To illustrate this embodiment, the central drive assembly 3 includes a motor I3-1, a horizontal frame plate 3-2, a central shaft 3-3, a central gear 3-4, a planetary shaft 3-5, a planetary gear 3-6, and a cross 3-7 and cutting knife I 3-8; motor I 3-1 is fixedly connected to the horizontal frame plate 3-2 through the motor frame, and the horizontal frame plate 3-2 is fixedly connected to the upper end of the inner wall of the crushing tube 2, and the horizontal frame plate 3-2 Located above the guide ring 2-2, the output shaft of the motor I3-1 is connected to the central shaft 3-3 through a coupling, and the central shaft 3-3 is rotatably connected to the middle of the horizontal frame plate 3-2 through a bearing with seat, and the center The gear 3-4 is fixedly connected to the central shaft 3-3, and the left and right sides of the central gear 3-4 are respectively meshed with a planetary gear 3-6, and the two planetary gears 3-6 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com