Tailor-welded blank hydraulic partitioning and side pressing forming device and forming method thereof

A technology of tailor-welded blanks and blocks, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., to achieve the effects of simplicity, convenience, reduced manufacturing costs, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and example operations. The following implementation examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

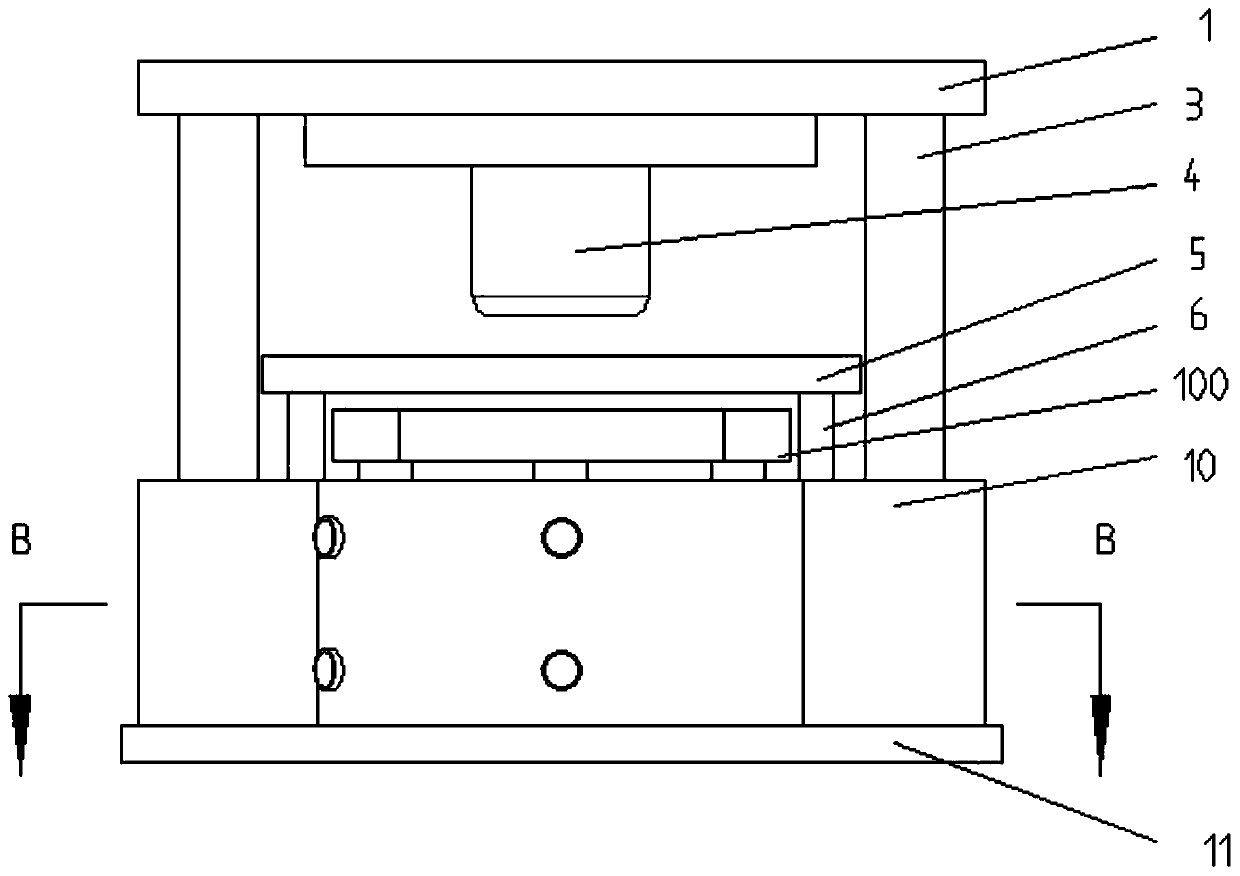

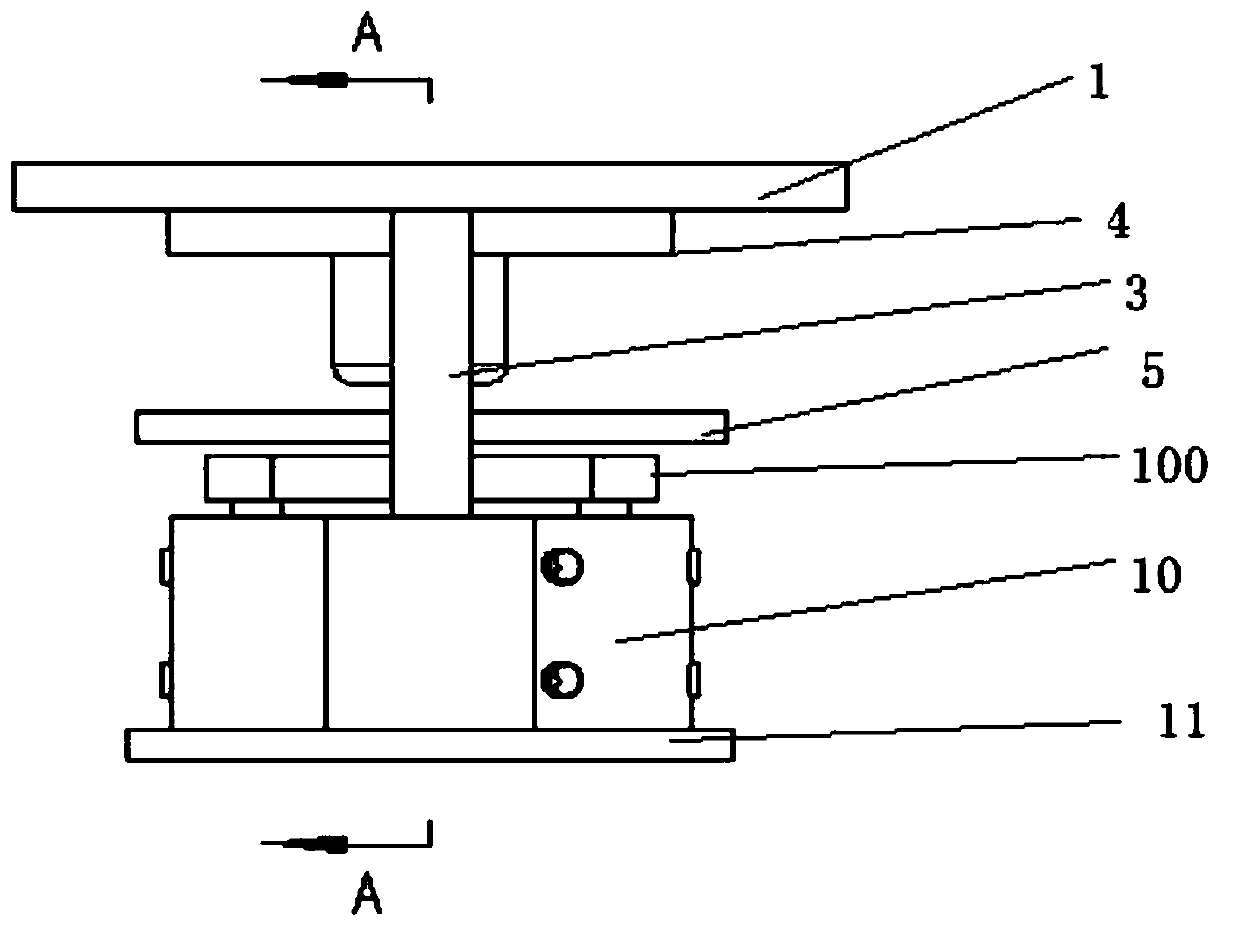

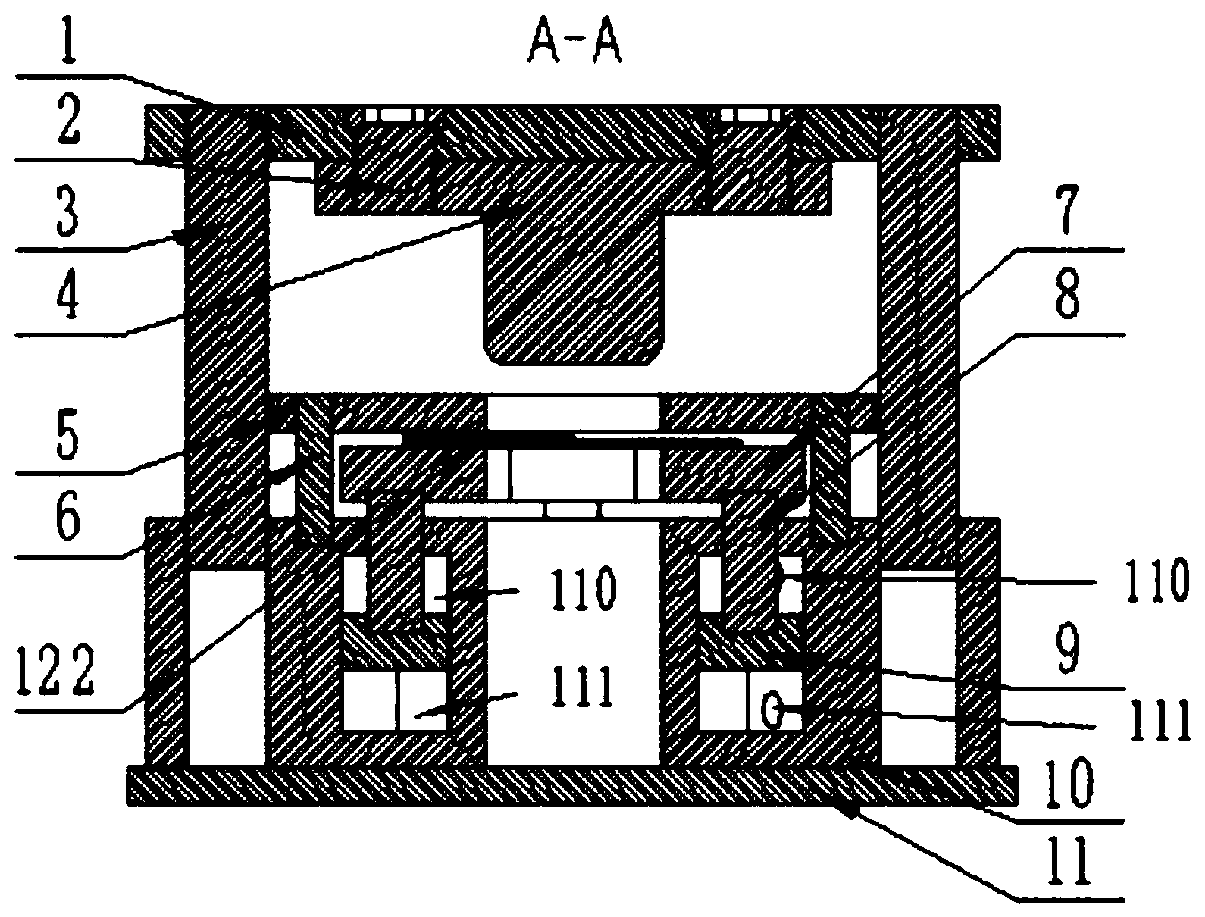

[0037] The invention provides a hydraulic segmented edge forming device for tailor welded blanks, such as Figure 1 to Figure 6 As shown, it includes an upper die base 1 , a hexagon socket head cap bolt 2 , a column 3 , a punch 4 , a blank holder mechanism 100 , a hydraulic cylinder cavity 10 and a lower die base 11 . A hydraulic cylinder cavity 10 is fixedly arranged on the lower mold base 11 , and a blank-holding mechanism 100 is arranged on the hydraulic cylinder cavity 10 , and the punch 4 is installed on the upper mold base 1 . As the upper die base 1 moves up and down, the tailor welded blank 122 set in the blank holder mechanism 100 is drawn and formed.

[0038] Tailored welded blanks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com