Fiber Channel Mechanism for Free End Spinning Device with Locking Connection

A fiber guide channel and free end technology, applied in the field of fiber guide channel mechanism, can solve problems such as complex processing, achieve high position reliability, shorten downtime, and shorten assembly and adjustment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

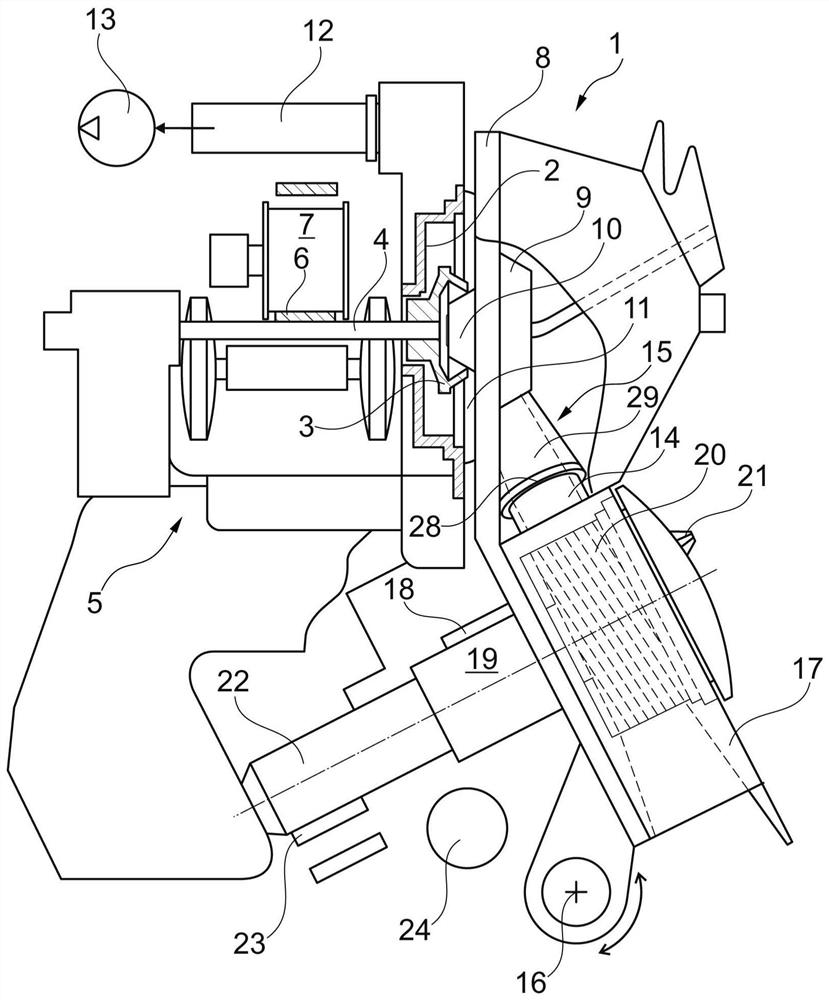

[0073] figure 1 An open-end spinning device 1 is shown schematically. Such an open-end spinning device 1 includes, as known, a rotor housing 2 in which a spinning rotor 3 rotates at a high speed.

[0074] The spinning rotor 3 is supported here with its rotor shaft 4 in a bearing cam of a so-called bearing disc 5 and is frictionally driven by means of a tangential belt 6 along the machine length which is subjected to the action of a pressure roller 7 . The axial fixing of the rotor shaft 4 takes place, for example, by means of permanent magnet thrust bearings.

[0075] The rotor housing 2 , which is itself open to the front, is closed during spinning operation by means of a pivotally mounted cover 8 . A channel plate 9 is incorporated into the cover part 8 , which abuts the rotor housing 2 with a circumferential seal 11 . The channel plate 9 has receptacles for exchangeable channel plate adapters 10 .

[0076] The pneumatic line 12 connects the rotor housing 2 to a negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com