A construction device and construction method for road vibration and noise reduction

A technology of vibration reduction and noise reduction, construction device, applied in road safety devices, roads, roads, etc., can solve the problems of high noise, high energy loss, low effective work rate, etc., to reduce vibration noise, reduce vibration loss, The effect of reducing vibration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

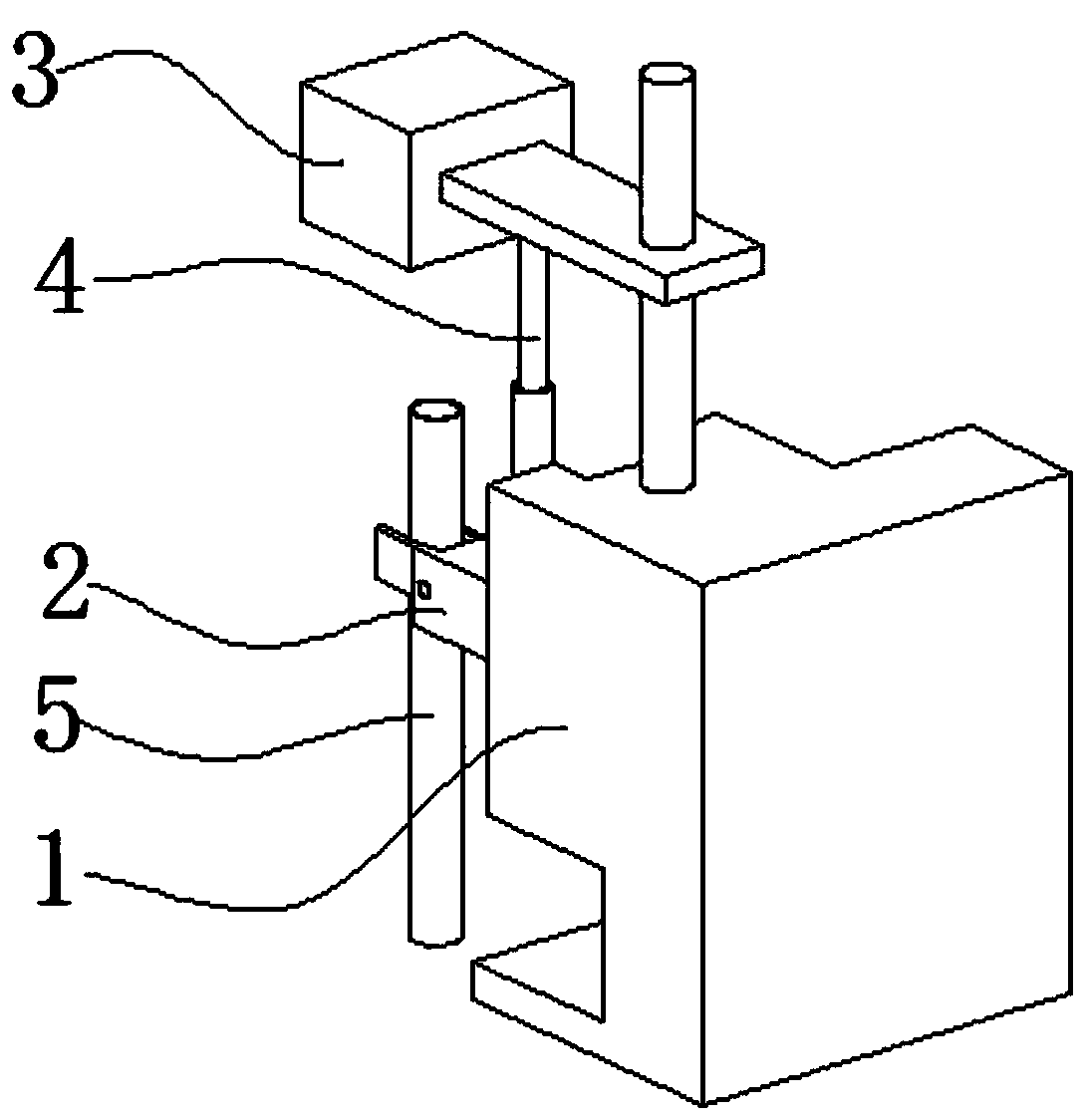

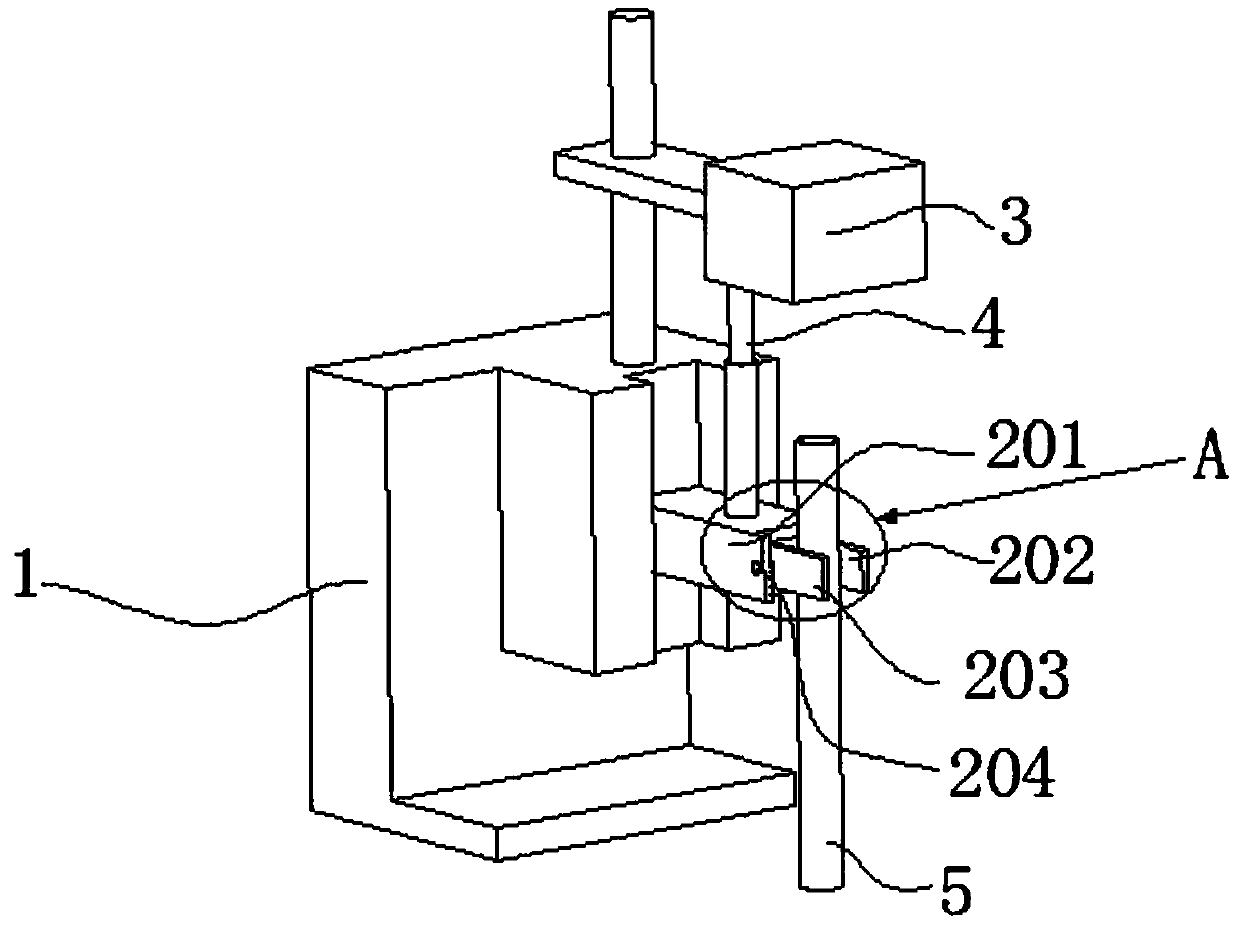

[0043] Such as figure 1 , figure 2 As shown, a road vibration and noise reduction construction device is used to install a railing 5; it includes a support base 1, a clamping device 2, an impact device 3 and a pre-transmission device 4, and one end of the clamping device 2 slides It is connected to the support base 1 and can move along the vertical space, and the other end is used to clamp the railing 5; the impact device 3 is connected to the support base 1; the impact device 3 is located on the clamping device 2 Above; the impact device 3 moves from top to bottom to form kinetic energy and then give the railing 5 a tendency to move downward; the pre-transmission device 4 is used to form a part of the impact device 3 before the impact device 3 contacts the railing 5 The kinetic energy is transferred to the railing 5.

[0044] Specifically, such as Figure 5 As shown, the clamping device 2 includes a mechanical arm 201, a left splint 202 and a right splint 203; one end of ...

Embodiment 2

[0050] With embodiment 1, difference is: as Figure 4 As shown, the pre-transmission device 4 includes a sleeve 405, a connecting rod 406 and a spring 407; the bottom of the sleeve 405 is connected to the mechanical arm 201 or the clamping device 2; the bottom of the connecting rod 406 is inserted In the sleeve 405 , the top is connected with the impact device 3 ; one end of the spring 407 is connected with the sleeve 405 or the mechanical arm 201 , and the other end is connected with the bottom of the connecting rod 406 .

[0051] In this embodiment, the connecting rod moves downward under the action of the impact device, the spring enters the compressed state from the stretched state, and gives the sleeve a thrust to move downward, and the clamping device moves downward, driving the railing to move downward, and the impact device Part of the kinetic energy generated from top to bottom is transmitted to the railing, so that the railing has a certain initial descending velocit...

Embodiment 3

[0053] A kind of construction method, use the construction device of road vibration reduction and noise reduction described in embodiment 1, the following content is its specific description:

[0054] A kind of construction method, its concrete steps are:

[0055] a. Put the railing 5 between the left clamping plate 202 and the right clamping plate 203, rotate the two-way threaded column 204, the left clamping plate 202 and the right clamping plate 203 move close to each other and clamp the railing 5 tightly;

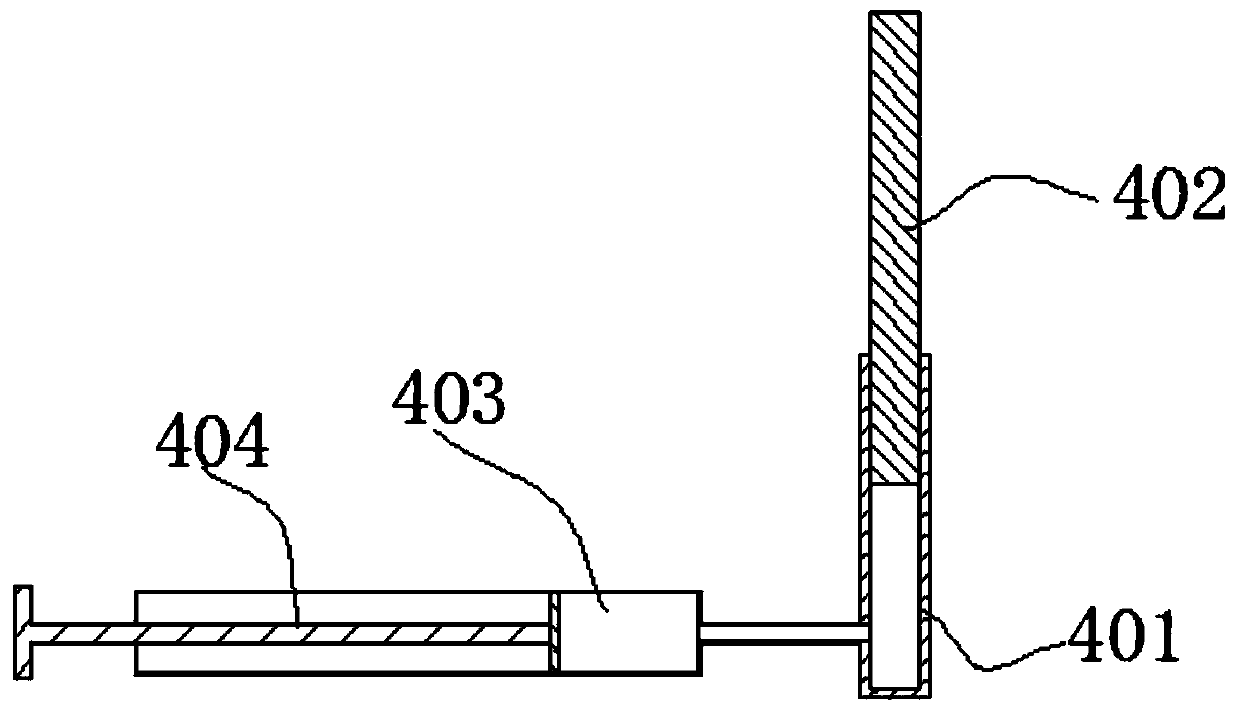

[0056] b. The impact device 3 moves from top to bottom. Before contacting the top of the railing 5, the impact device 3 moves from top to bottom, and the hydraulic rod 402 moves downward, pushing the hydraulic oil in the hydraulic cylinder 401 to flow into the auxiliary cylinder 403, giving hydraulic pressure The thrust of the cylinder 401 moving downward, the clamping device 2 moves downward, drives the railing 5 to move downward, and part of the kinetic energy generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com