Nonlinear energy sink with segmented linear beams applied to rotor system

A nonlinear energy trap, piecewise linear technology, applied in the direction of rotational vibration suppression, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems of narrow vibration suppression frequency band, reduced reliability, complex structure, etc. Strong, easy to adjust, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

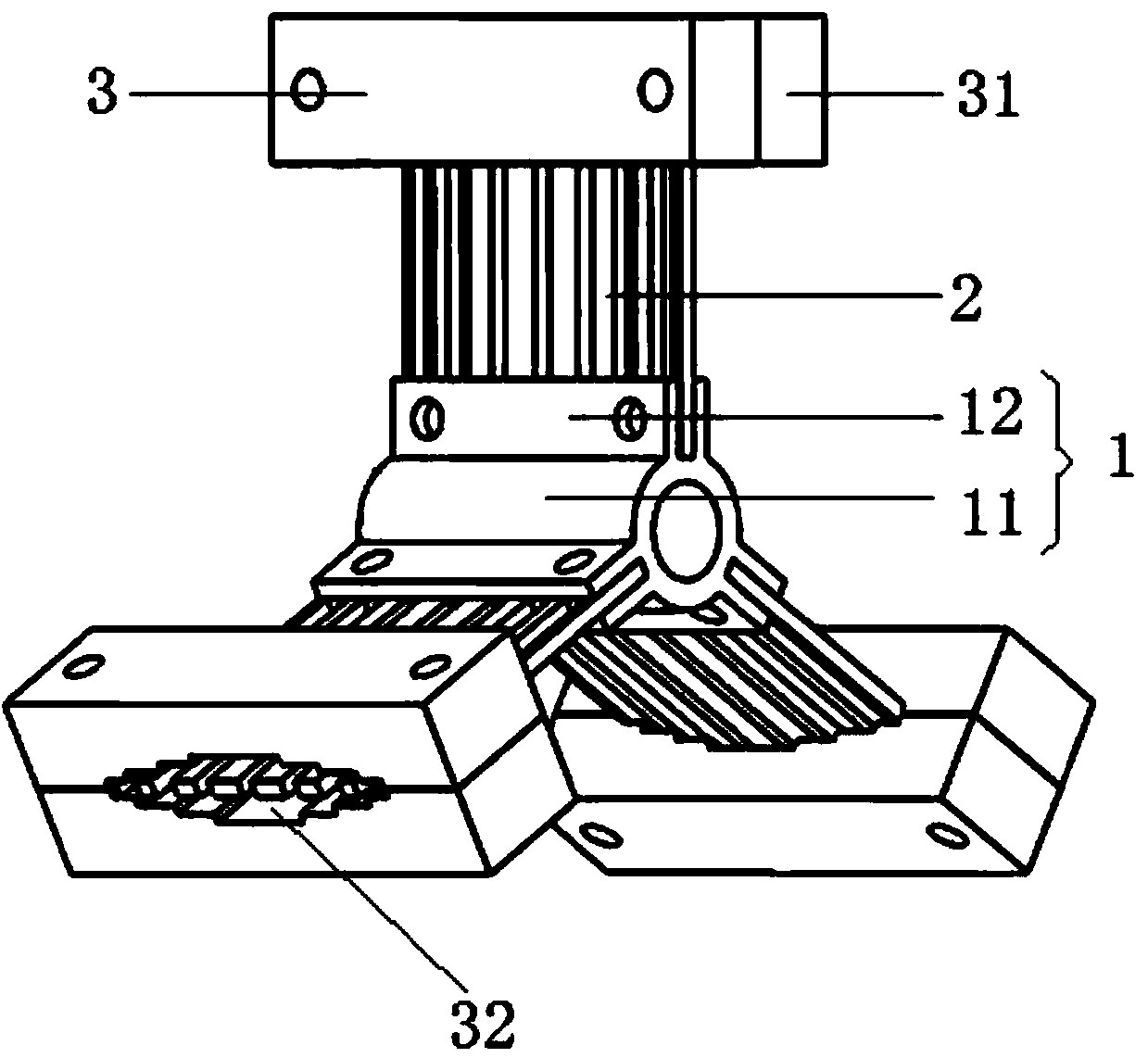

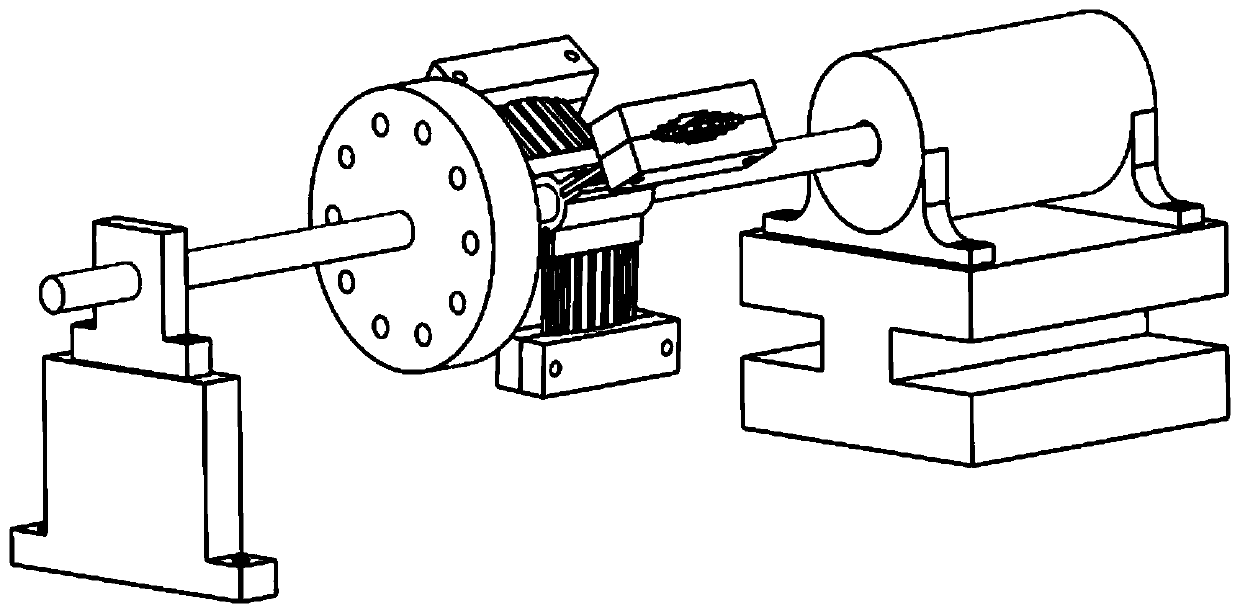

[0027] Such as figure 1 and figure 2 As shown, a nonlinear energy well with a segmented linear beam applied to a rotor system of the present invention includes: an NES frame 1 sleeved on the rotor shaft, a plurality of leaf springs 2 and a plurality of mass blocks 3 . One end of the leaf spring 2 is connected to the NES frame 1, and the other end is correspondingly connected to a mass block 3, and a plurality of leaf springs 2 are evenly arranged.

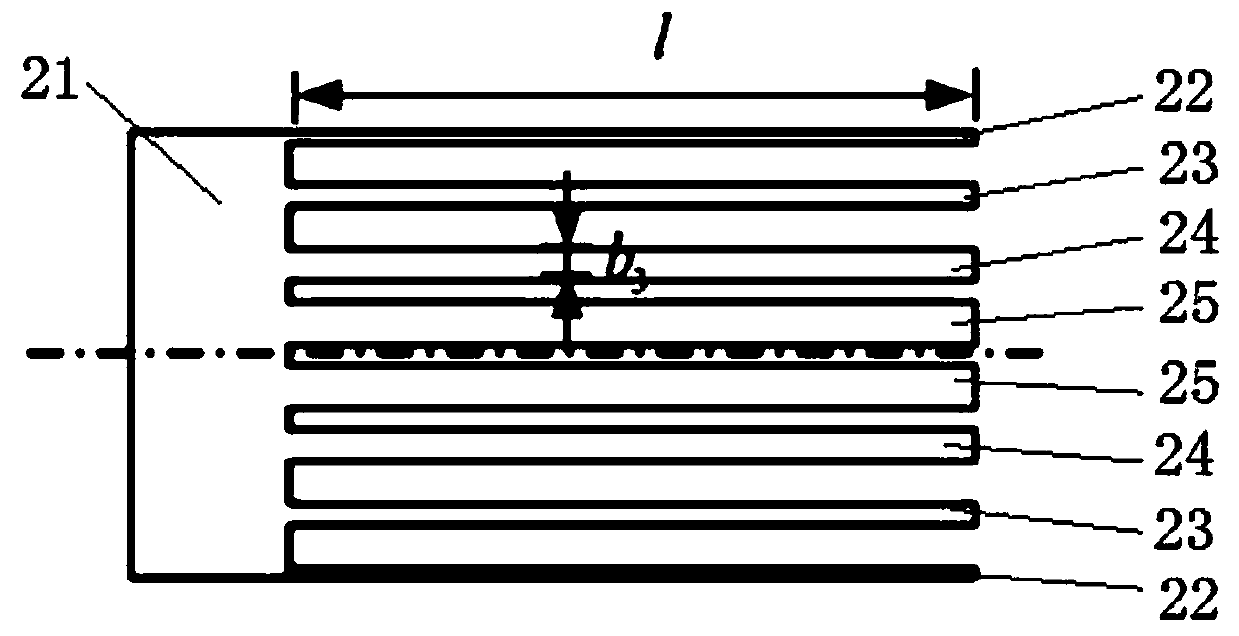

[0028] Such as image 3 As shown, the leaf spring 2 includes a connecting piece 21 and eight beams arranged on the connecting piece 21, and the eight beams include two connecting beams 22 symmetrically arranged from both sides of the connecting piece 21 to the middle, two first The segmented linear beams 23, the two second segmented linear beams 24 and the two third segmented linear beams 25, the eight beams have the same length and thickness, and the distance between adjacent beams decreases from both sides to the middle. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com