Convenient-to-use welding spot tensile resistance clamp for measuring welding spot tensile resistance of galvanized welded wire mesh

A tensile and convenient technology, applied in the direction of measuring devices, applying stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of low test efficiency, inflexibility, and large amount of consumables, etc., to reduce costs, The effect of improving test efficiency and saving test resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

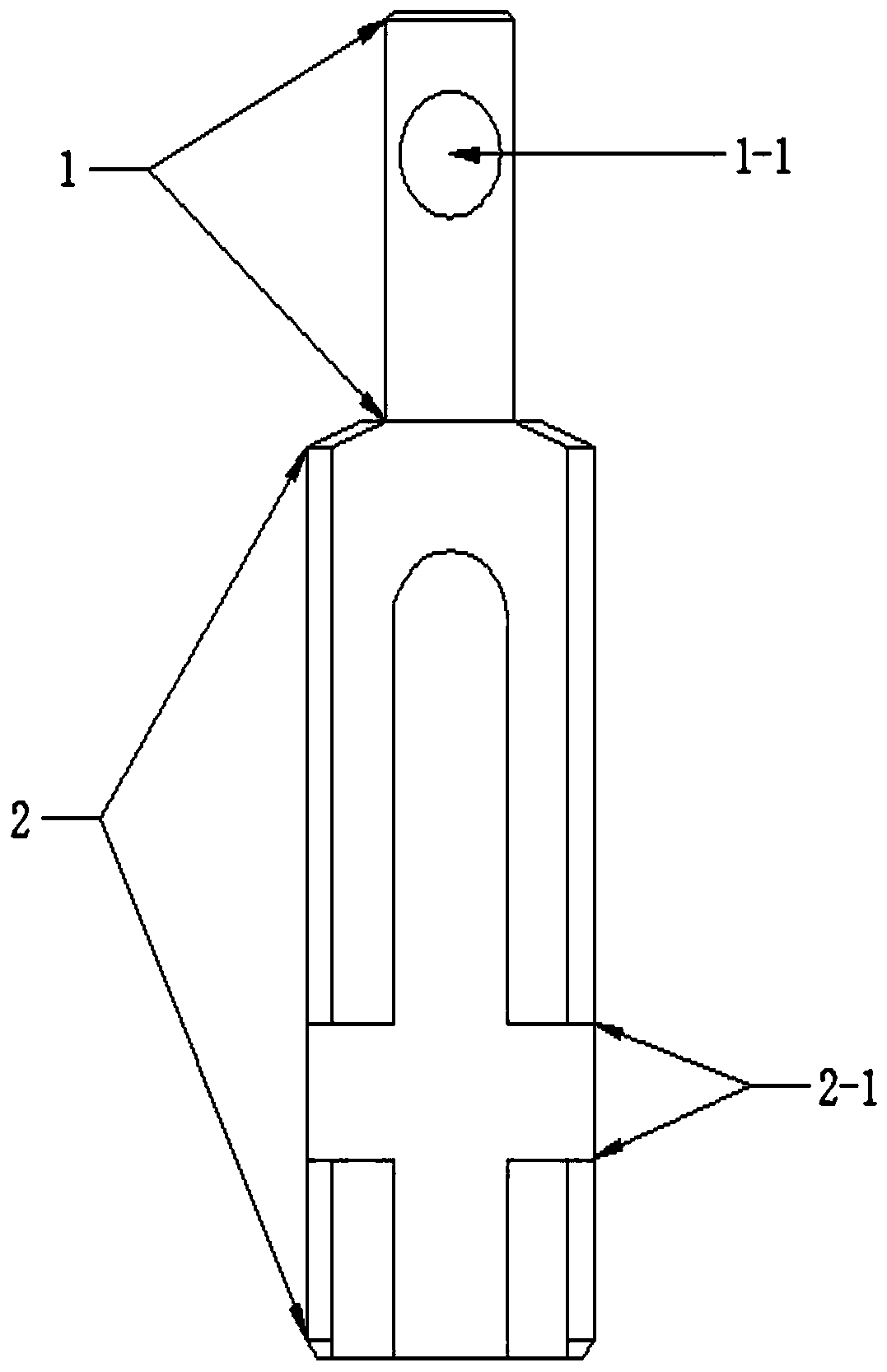

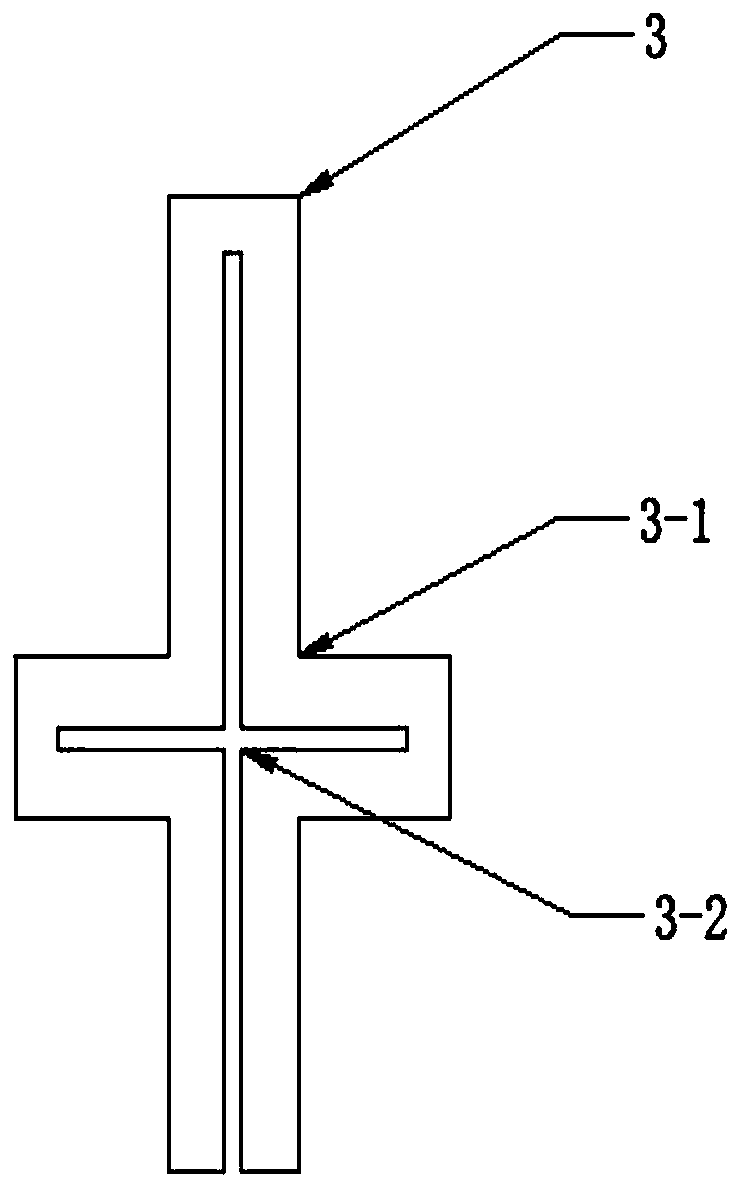

[0025] A convenient solder joint tensile force fixture for measuring the tensile force of solder joints of galvanized welded wire mesh, which is composed of a fixture connector 1, a fixture carrier body 2 and a cross-shaped gasket 3. 1. The structures of the jig carrier body 2 and the cross-shaped gasket 3 are as follows:

[0026] They are as follows:

[0027] Fixture connector 1, such as figure 1 As shown, its external structure is a cylinder, and the cylinder is provided with a hole-shaped bolt connection port 1-1 for connection through a cylindrical bolt, and the bottom of the cylinder is connected with a fixture carrier body 2;

[0028] Fixture carrier 2, such as figure 1 As shown, its shape structure is a half cylinder, the top of the half cylinder is connected to the bottom of the fixture connector 1, and a cross-shaped notch 2-1 is provided at the plane section of the half cylinder;

[0029] Cross spacer 3, such as figure 2 As shown, its external structure is a cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com