Elastomeric film-forming compositions and associated articles and methods

A composition and body product technology, applied in chemical instruments and methods, layered products, drug delivery, etc., can solve problems such as inappropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0128] Preparation of Elastomeric Film-Forming Compositions

[0129] Compositions for producing elastomeric films can be prepared by mixing components (a), (b) and (c) and any optional additional components in a liquid such as water. Methods may include pre-preparing individual components at specific concentrations (total solids), diluting the components, if necessary, combining, and making any further dilutions as necessary to achieve the final total solids set for the composition.

[0130] Suitable additives or other components as described above may be included in the composition and may be added to the combination of components (a) and (b) prior to the addition of the crosslinker (c), or to both In a mixture of (a), (b) and (c).

[0131] Typically, the powder components of the composition are combined and ground using suitable grinding equipment to reduce the particle size to a suitable range. Preferably, the average particle size is less than 5 microns. A uniform parti...

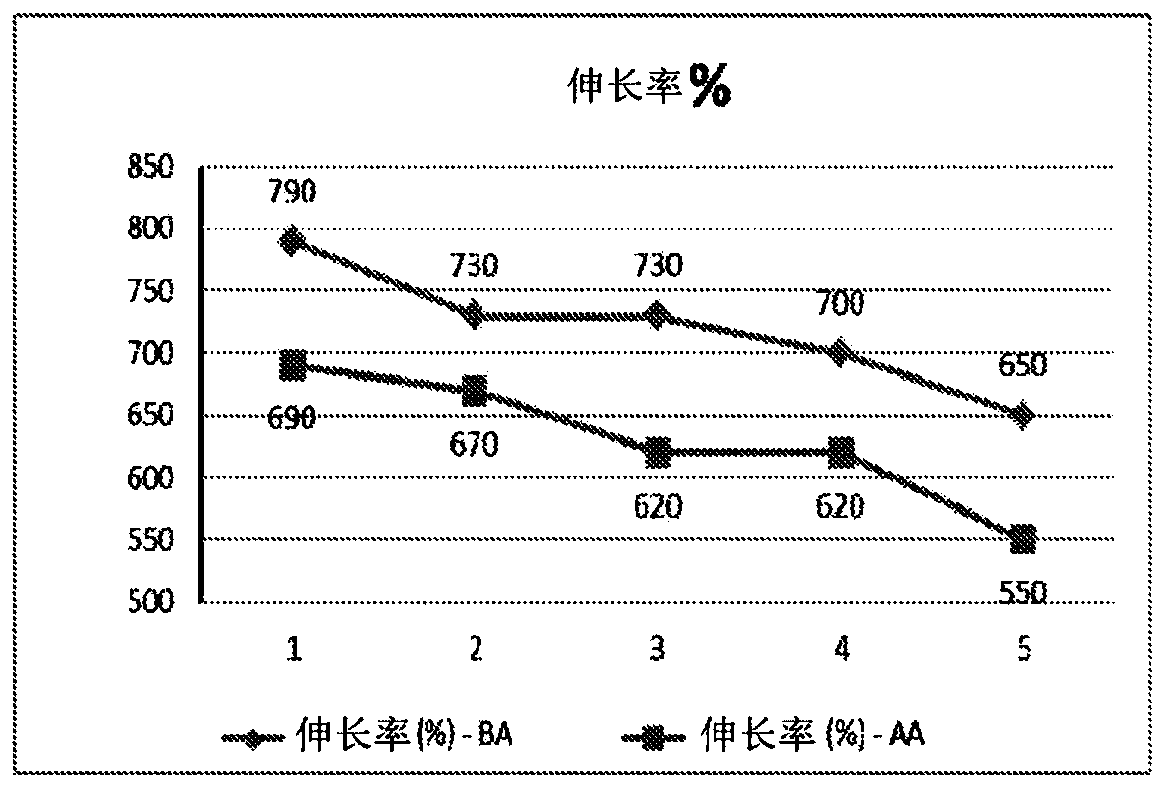

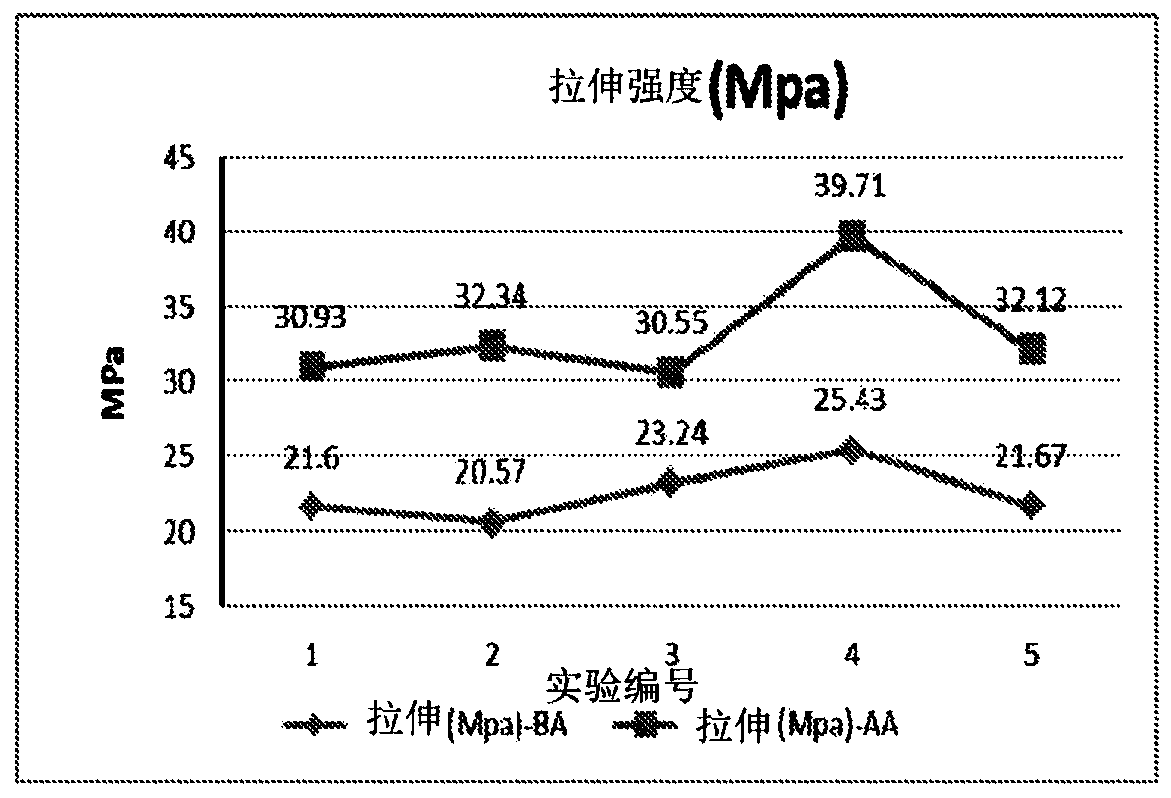

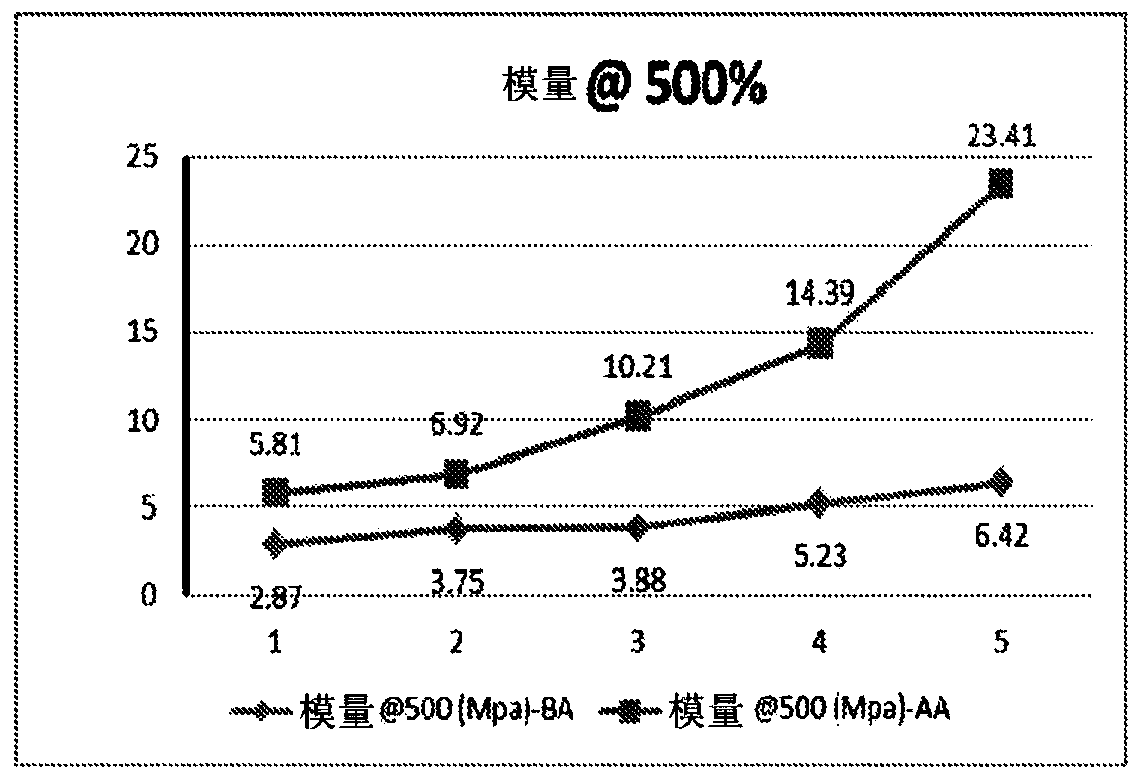

preparation Embodiment 6 to 9

[0217] The formulations having the compositions shown in Tables 2 and 3 were based on different relative amounts of polychloroprene and carboxylated butadiene-based elastomer. In Examples 1 to 5, there were variations in the amount of crosslinker and other components present in the composition. Examples 6 to 9 were then prepared as follows: Based on fixed amounts of crosslinker and other components (based on the amounts used in Example 5), only the relative amounts of polychloroprene and carboxylated butadiene-based elastomer occurred Variety. When the results of Examples 6 to 9 and Example 5 are considered together, they show a trend when varying the relative amount of elastomer from 5% to 27%.

[0218] Gloves were prepared from the compositions following the general procedure shown above.

[0219] Table 2

[0220] Example 1 Example 2 Example 3 Example 4 Example 5 Polychloroprene 5 10 15 20 27 ZnO 0.25 0.35 0.45 0.55 0.75 ZDBC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com