Cleaning heads for floor cleaning machines

A ground cleaning and cleaning head technology, applied in the field of cleaning equipment, can solve problems such as large water output, water leakage, and untidy ground to be cleaned, and achieve the effect of smooth water supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

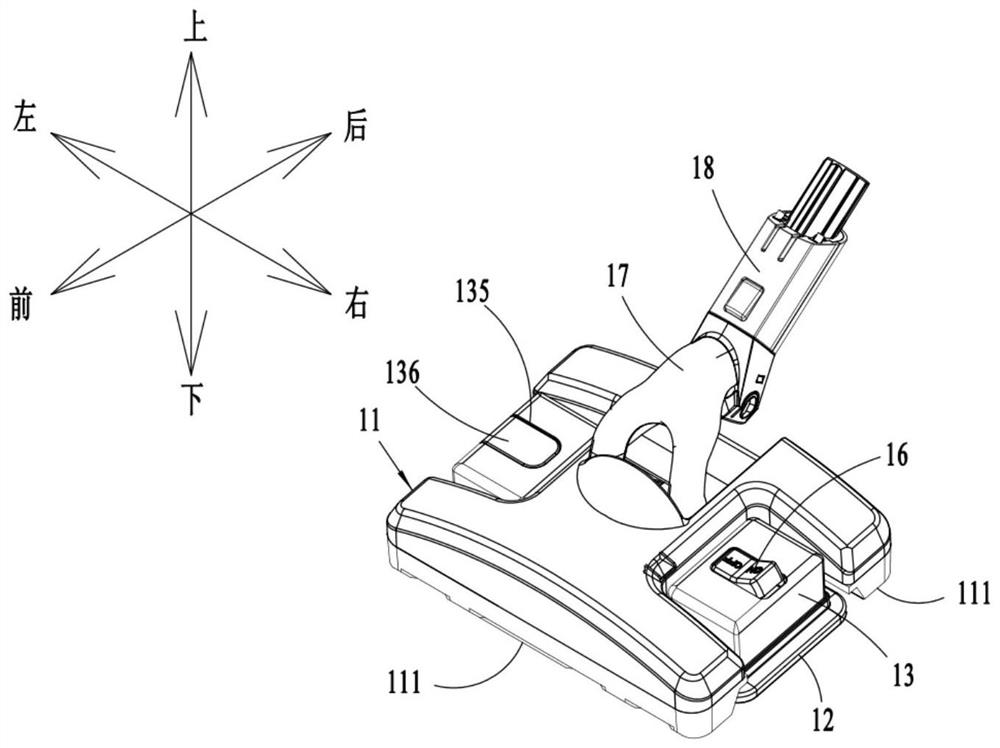

[0044] In order to describe the technical content, structural features, achieved goals and effects of the invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings. Wherein, the upper, lower, left, right, front and rear positional relationships described in this embodiment are related to figure 1The respective positional relationships shown in correspond to each other.

[0045] The cleaning head of the present invention is mainly used on floor cleaning machines, which are equipment for vacuuming and / or cleaning the ground to be cleaned, for example, it can be a wet and dry vacuum cleaner, or a floor washing machine .

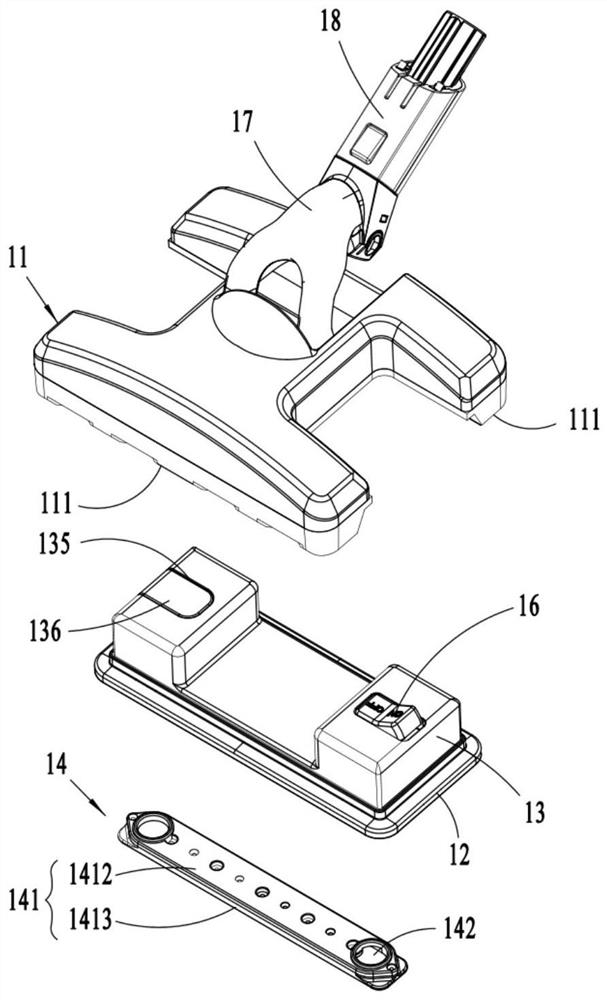

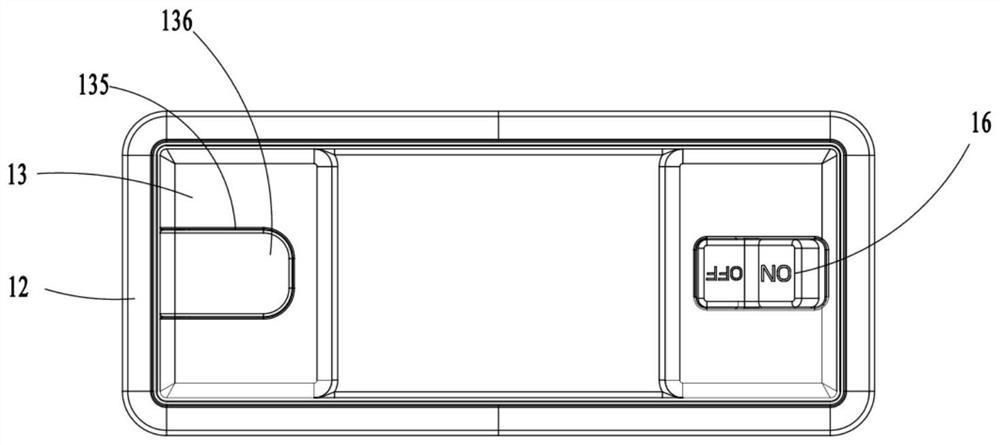

[0046] Such as Figure 1-Figure 2 As shown, the cleaning head includes a cleaning head body 11 , a bottom plate 12 , a water supply tank 13 , a water distributor 14 , a rotary joint 17 and a suction channel 18 .

[0047] Wherein, the rotating connection head 17 is connected to the cleaning hea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap