Supported multi-metal component catalyst, its preparation method and application, and cycloalkane hydrogenolysis ring-opening method

A metal component and catalyst technology, which is applied in the field of supported multi-metal component catalysts and their preparation, can solve the problems of low ring-opening activity and selectivity of cycloalkane hydrogenolysis, and achieve excellent catalytic performance and high catalytic cycloalkane hydrogenolysis ring-opening activity , the effect of low cracking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

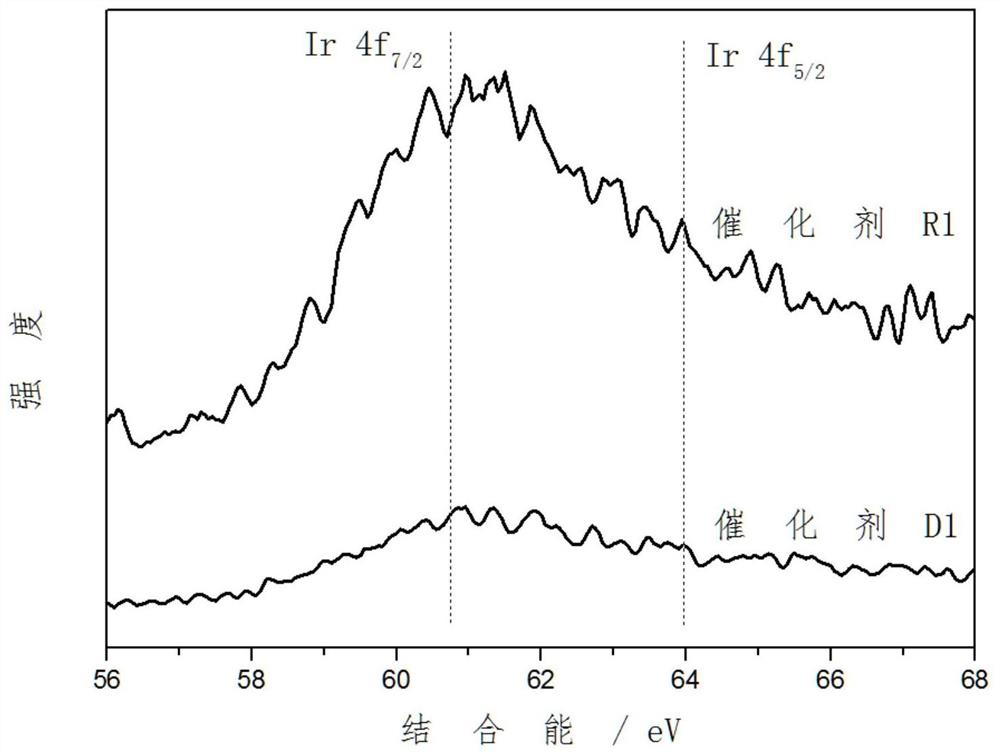

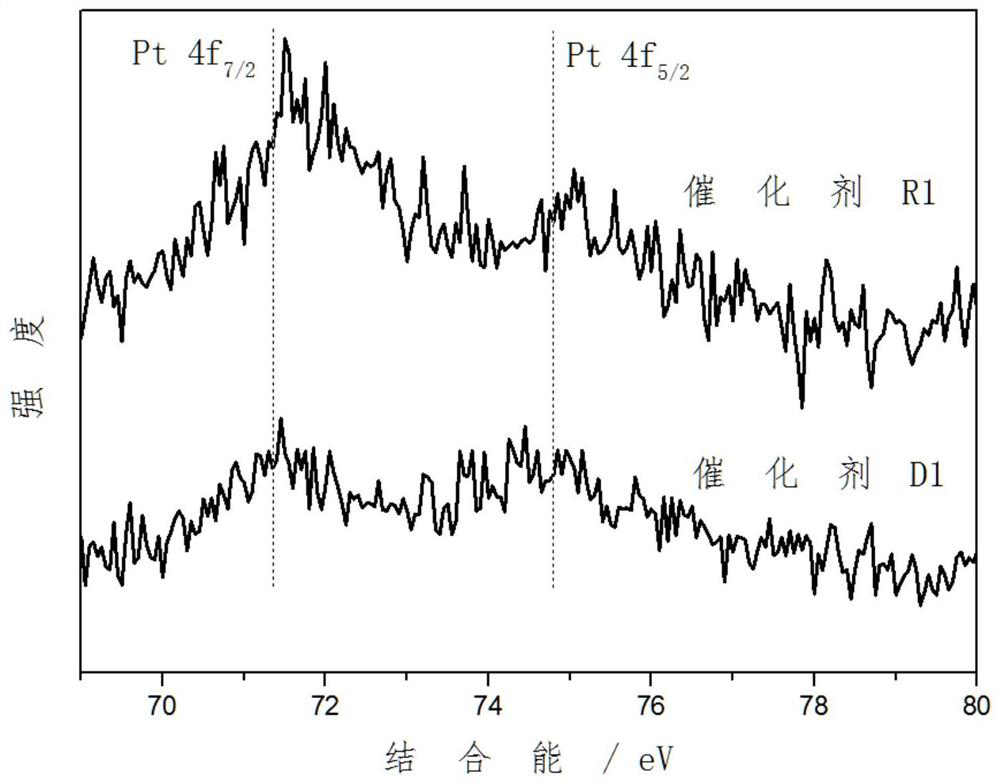

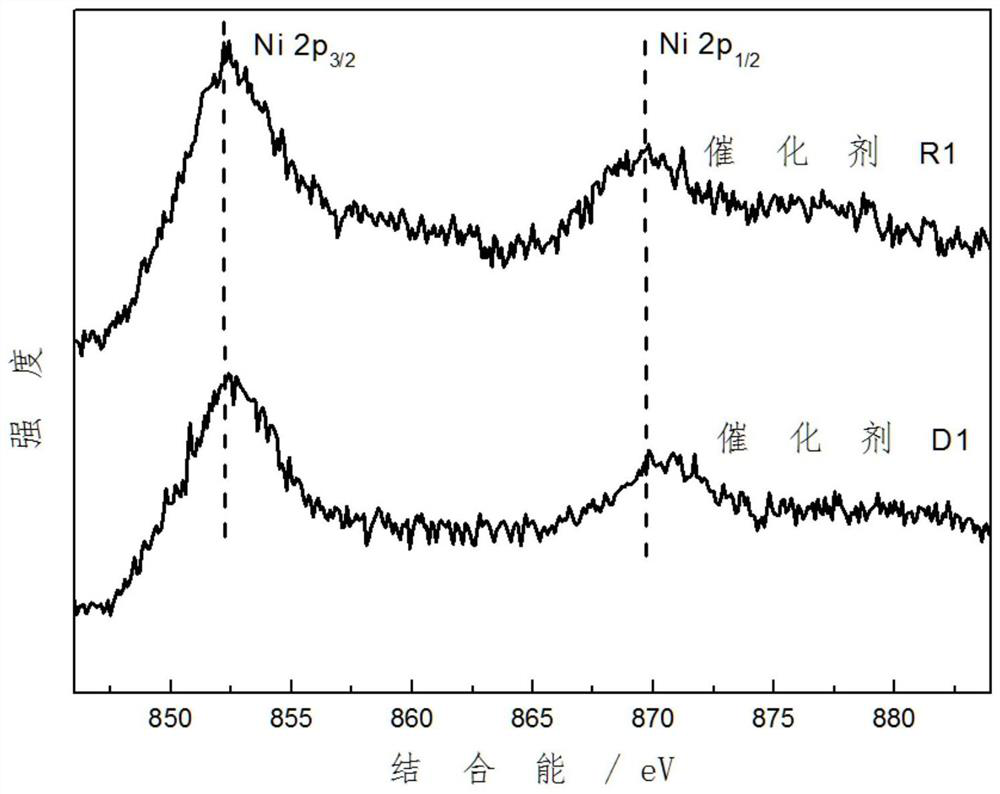

[0028] According to a preferred embodiment of the present invention, the catalyst satisfies [(M 2 +M 3 ) / M 1 ] XPS / [(M 2 +M 3 ) / M 1 ] XRF =2-8, it is further preferred that the catalyst satisfies [(M 2 +M 3 ) / M 1 ] XPS / [(M 2 +M 3 ) / M 1 ] XRF =2.5-5.

[0029] According to a preferred embodiment of the present invention, the catalyst satisfies (M 2 / M 3 ) XRF =0.05-1.5, preferably the catalyst satisfies (M 2 / M 3 ) XRF =0.1-1, further preferably the catalyst satisfies (M 2 / M 3 ) XRF = 0.6-0.7. The inventors of the present invention found that specific (M 2 / M 3 ) XRF , that is, the weight ratio of the second metal component to the third metal component in the catalyst characterized by X-ray fluorescence spectrum in terms of metal elements, so that the catalyst performance of the catalyst is further improved.

[0030] The present invention uses X-ray photoelectron spectroscopy to characterize the surface atomic composition of the catalyst, uses X-ray...

Embodiment 1

[0072] This example is used to illustrate the catalyst provided by the present invention and its preparation method.

[0073] According to the required metal salt content of the equal volume impregnation method, 32.4 milliliters of nickel nitrate and iridium chloride impregnation solution containing 167 grams per liter of nickel and 2.22 grams per liter of iridium were prepared. Decant the impregnation solution into 40 g of SiO 2 -Al 2 o 3 Carrier (Sasol amorphous silica-alumina, average particle size 40-80 microns, the same below), after stirring at 25°C for 4 hours, drying at 120°C, calcination at 350°C for 4 hours, hydrogen reduction at 350°C for 4 hours, The hydrogen pressure is 0.1 MPa. Reduce to room temperature after reduction, and add 48.6 milliliters of iridium chloride containing 2.96 grams per liter of iridium and 2.96 grams per liter of platinum and platinum dichlorotetraammine in 48.6 milliliters under a hydrogen atmosphere. Blow dry with hydrogen. Then by O ...

Embodiment 2

[0091] This example is used to illustrate the catalyst provided by the present invention and its preparation method.

[0092] According to the required metal salt content of the equal volume impregnation method, 32.4 milliliters of nickel nitrate and iridium chloride impregnation solution containing 167 grams per liter of nickel and 2.22 grams per liter of iridium were prepared. The impregnating liquid is decanted to 40 grams of hydrogen type Y-Beta composite molecular sieves-alumina carrier (prepared according to the carrier D1 of Example 1 of CN101992120A, the following is the same), stir evenly at 25 ° C, after standing for 4 hours, through 110 ° C Drying, calcination at 500°C for 4 hours, hydrogen reduction at 350°C for 4 hours, hydrogen pressure at 0.1 MPa. Reduce to room temperature after reduction, and add 48.6 milliliters of iridium chloride containing 2.96 grams per liter of iridium and 2.96 grams per liter of platinum and platinum dichlorotetraammine in 48.6 millilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com