Automatic welding machine

An automatic welding machine, welding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor versatility and high manufacturing cost, save tooling costs, improve welding accuracy, and increase versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

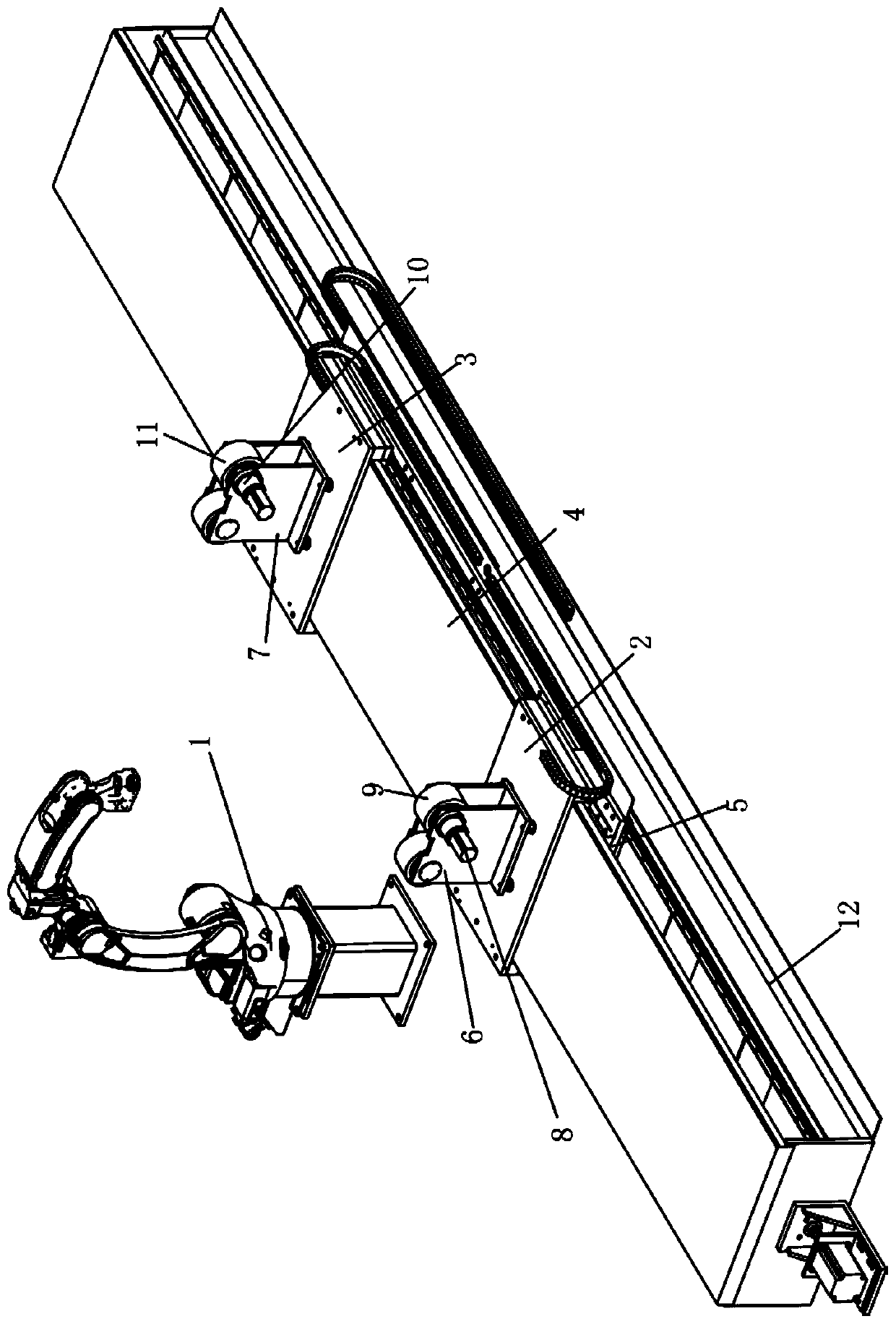

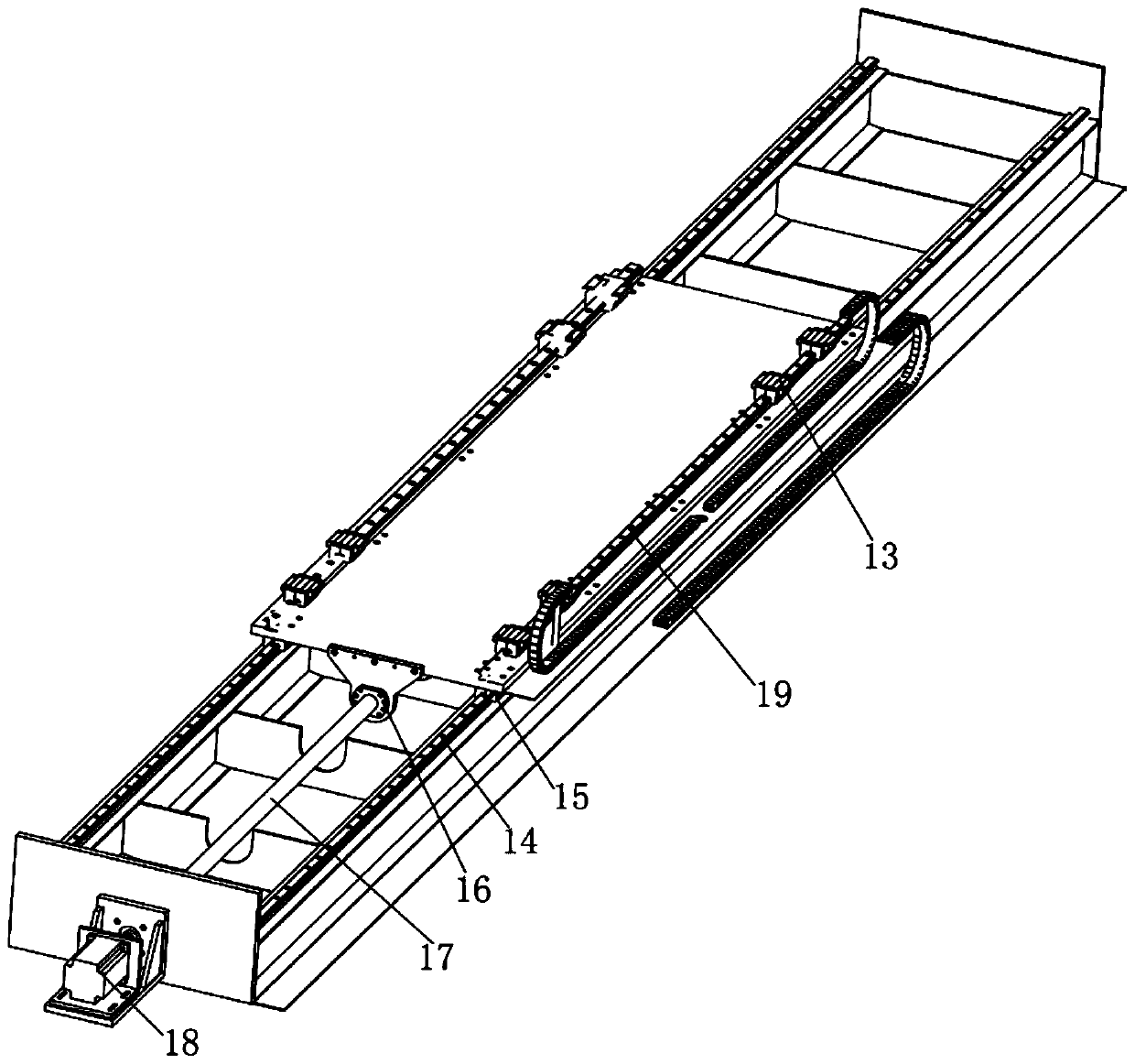

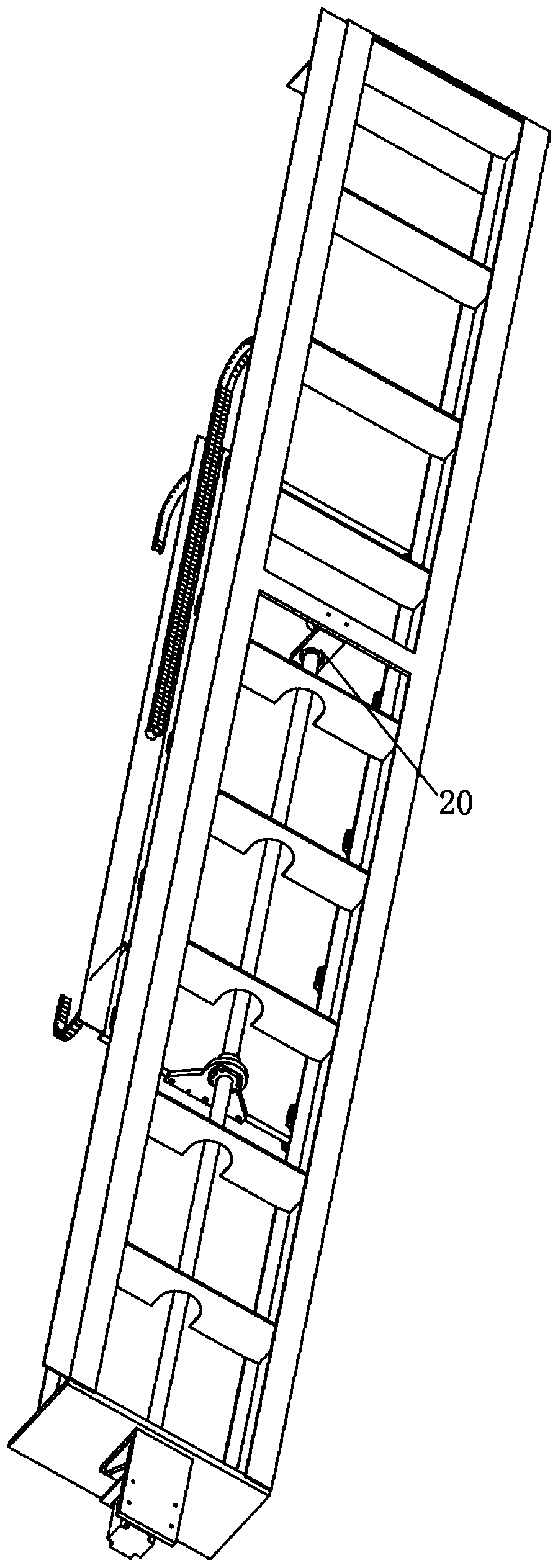

[0016] Such as figure 1 As shown, an automatic welding machine of the present invention includes a welding machine main body 1, a first mobile platform 2, a second mobile platform 3, a fixed plate 4, a mobile plate 5, a first bracket 6, a second bracket 7, a first Motor 8, the first roller 9, the second motor 10, the second roller 11 and the support frame 12; the welding machine main body 1 and the support frame 12 are respectively arranged on the ground; the first mobile station 2 and the second mobile station 3 are arranged on the moving plate 5 which can move left and right respectively; the first mobile platform 2 and the second mobile platform 3 pass through the fixe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap