Using method of building template in construction

A technology of building formwork and formwork, which is applied to the preparation of formwork/formwork/work frame, building components on site, construction, etc., can solve problems such as low construction efficiency, quality problems, and labor-intensive, and achieve improved construction quality and improved The effect of building efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

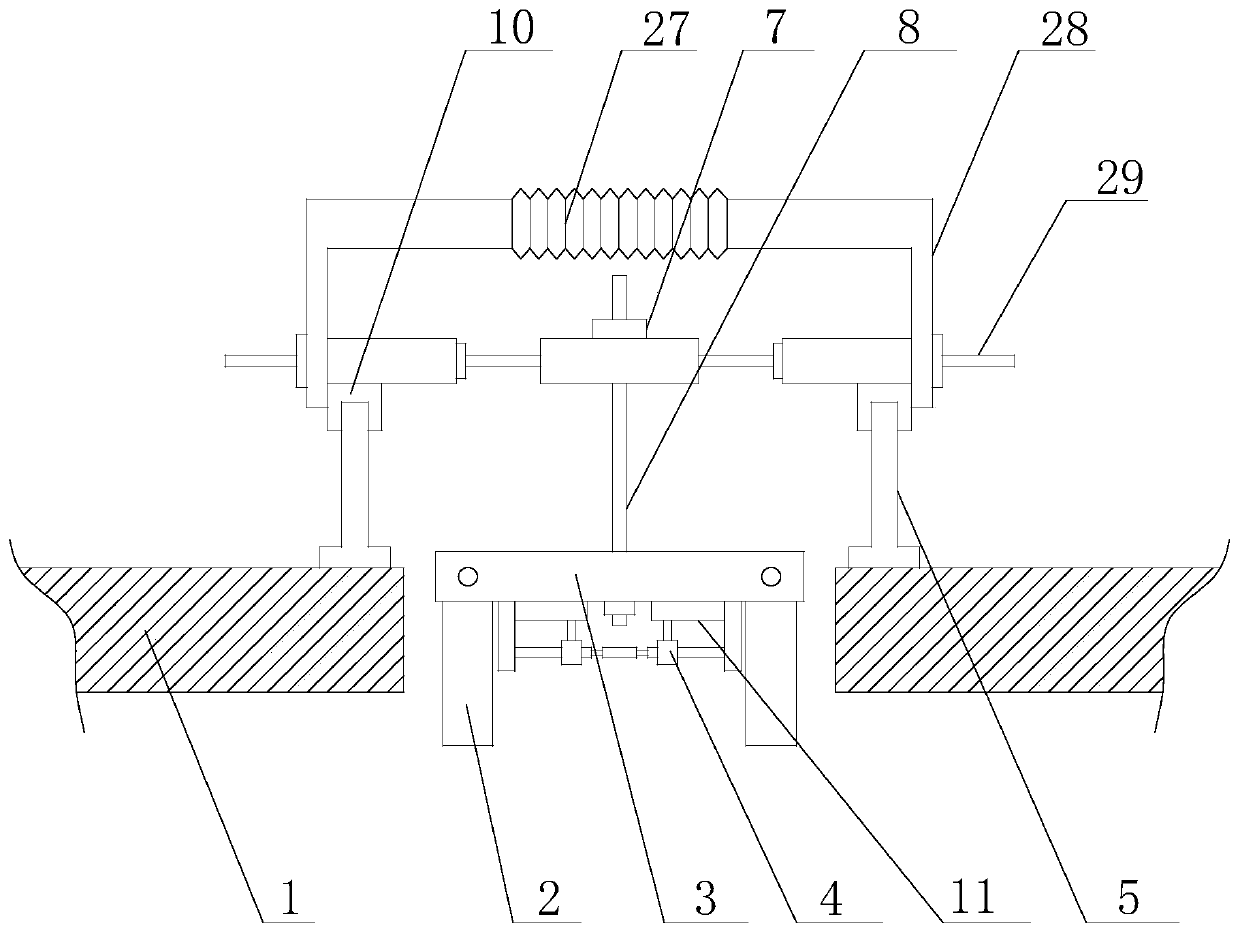

[0055] A method for using a building formwork in the present invention, 1. After finishing the pouring of the concrete 1 floor slabs on both sides of the post-cast belt 9, the support frame 5 is installed on the concrete 1 on both sides of the post-cast belt 9 to be corrected;

[0056] 2) Adjust the length of the horizontal plate 7 according to the width of the post-casting belt 9, and connect the moving block 10 with the support frame 5, so that the horizontal plate 7 is installed above the post-casting belt 9 to be poured;

[0057] 3) Install the connecting plate 28 and connect it with the adjusting rod 29, and use the baffle plate to protect the post-casting belt 9;

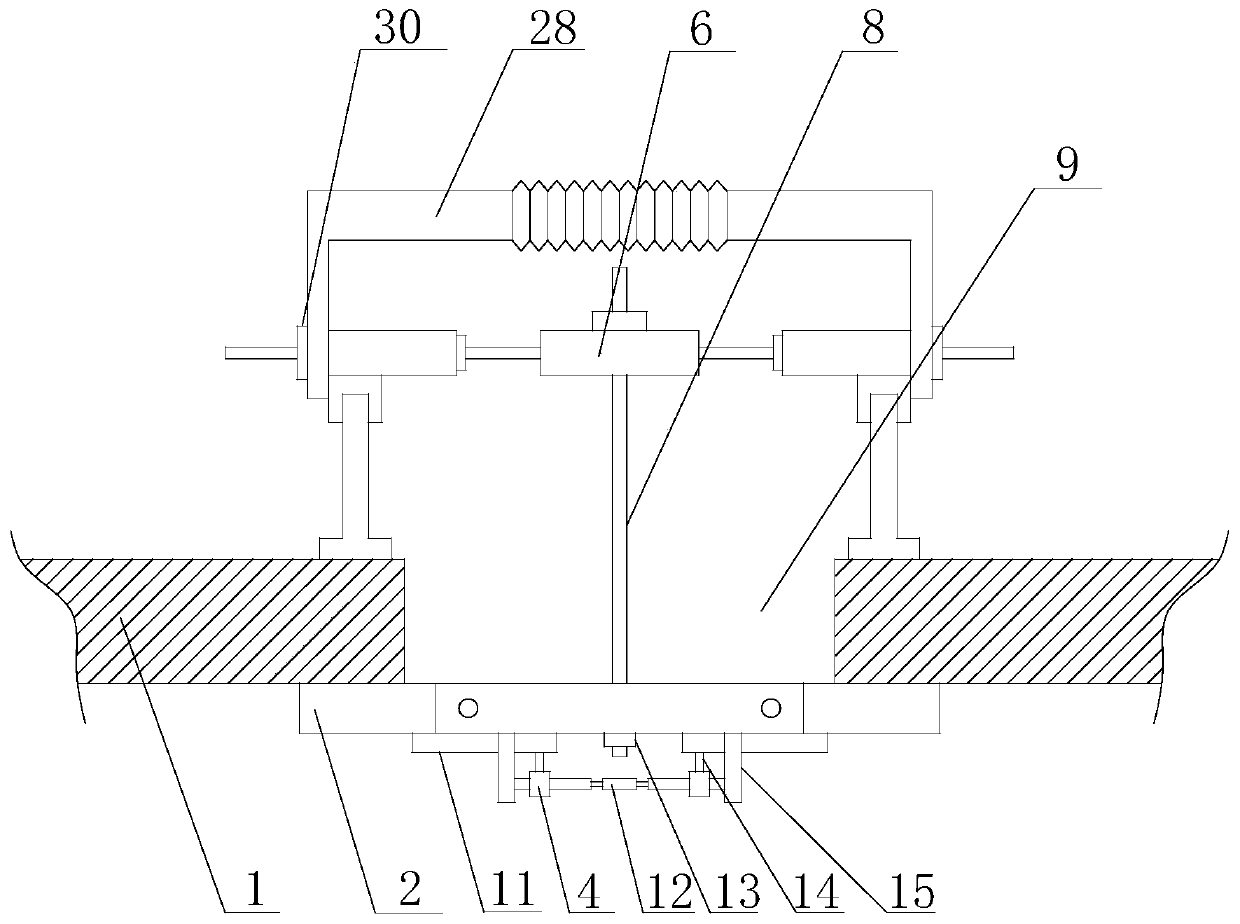

[0058] 4) When the post-casting belt 1 needs to be poured with concrete, the threaded rod 8 connected to the template 3 is connected to the horizontal plate 6 through the nut 7;

[0059] 5) Rotate the nut 7, and the threaded rod 8 drives the formwork 3 to move downwards along the vertical direction, so that th...

Embodiment 2

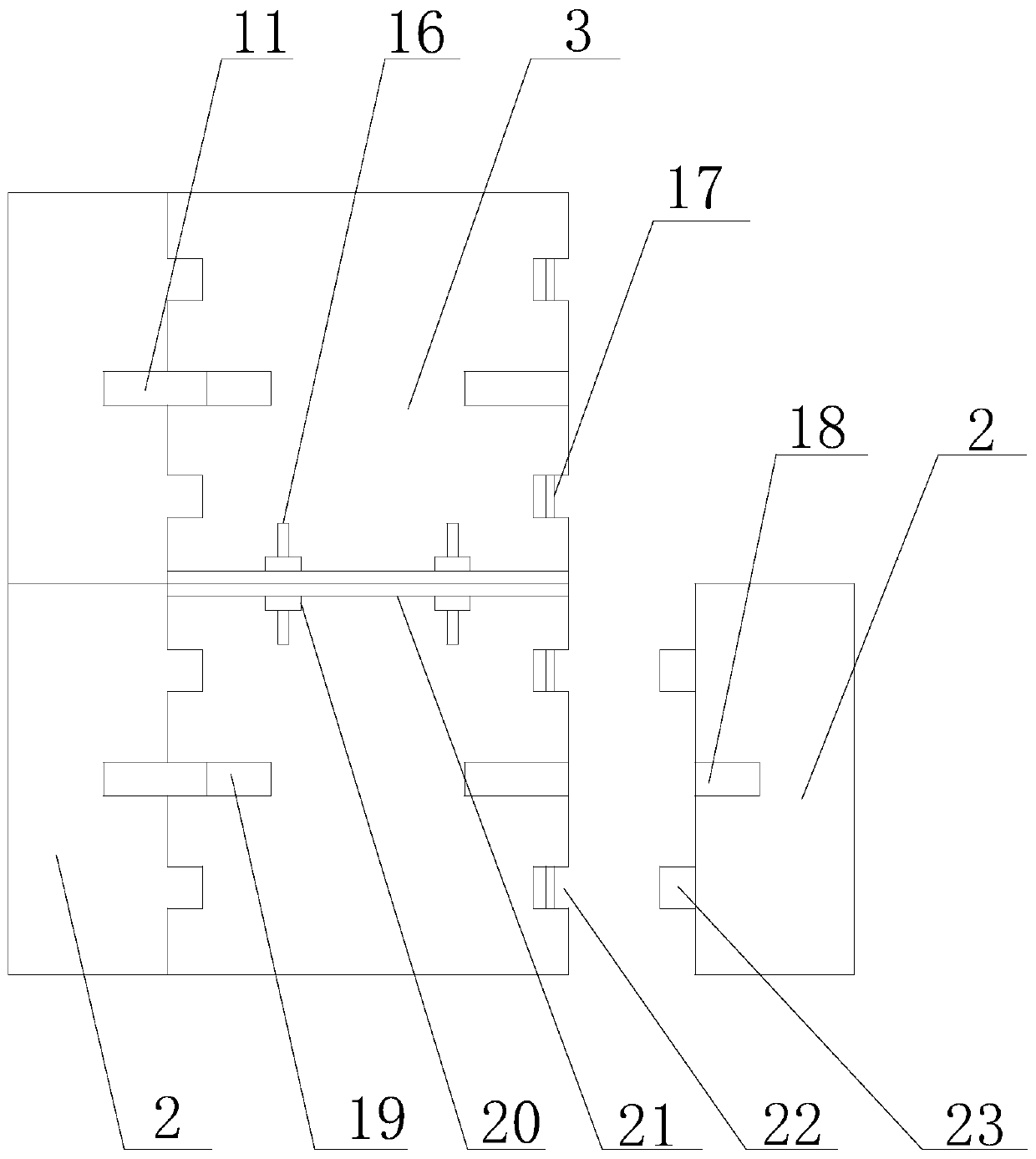

[0069] On the basis of Embodiment 1, the fixed assembly includes a rotating rod 12, two connecting blocks 15, and two moving plates 11. The connecting blocks 15 are respectively located on both sides of the axis of the template 3, and the two ends of the rotating rod 12 are respectively It is connected with two connecting blocks 15, and the rotating rod 12 can rotate in the connecting block 15. The moving plate 11 is located at the bottom of the template 3, and the moving plate 11 runs through the connecting block 15 horizontally. Rotating the rotating rod 12, the moving plate 11 can move along the horizontal direction in the connection block. The two ends of described rotating bar 12 are all provided with movable block 4, and movable block 4 is connected with rotating bar 12 by screw thread, and described movable block 4 is all provided with connecting rod 14, and connecting rod 14 is connected with moving plate 11, movable When the block 4 moves on the rotating rod 12, the c...

Embodiment 3

[0071] On the basis of Embodiment 2, two connecting grooves 22 are provided at both ends of the template 3, and two connecting blocks matching the connecting grooves 22 are provided on the side wall of the movable support plate 2 facing the direction of the template 3 23, the connecting block 23 is located in the connecting groove 22, the connecting groove 22 is also provided with a movable shaft 17, and the movable shaft 17 is inserted in the connecting block 23, and the connecting block 23 can rotate on the movable shaft 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com