Device for automatically spraying powder fireproof materials to rear part of coal mine combined mining support

A fully mechanized mining support and automatic spraying technology, applied in safety devices, fire prevention, dust prevention, etc., can solve problems such as low efficiency, negative impact on the health of workers, heavy physical labor, etc., to achieve the liberation of physical labor and ingenious structural design , the effect of uniform spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

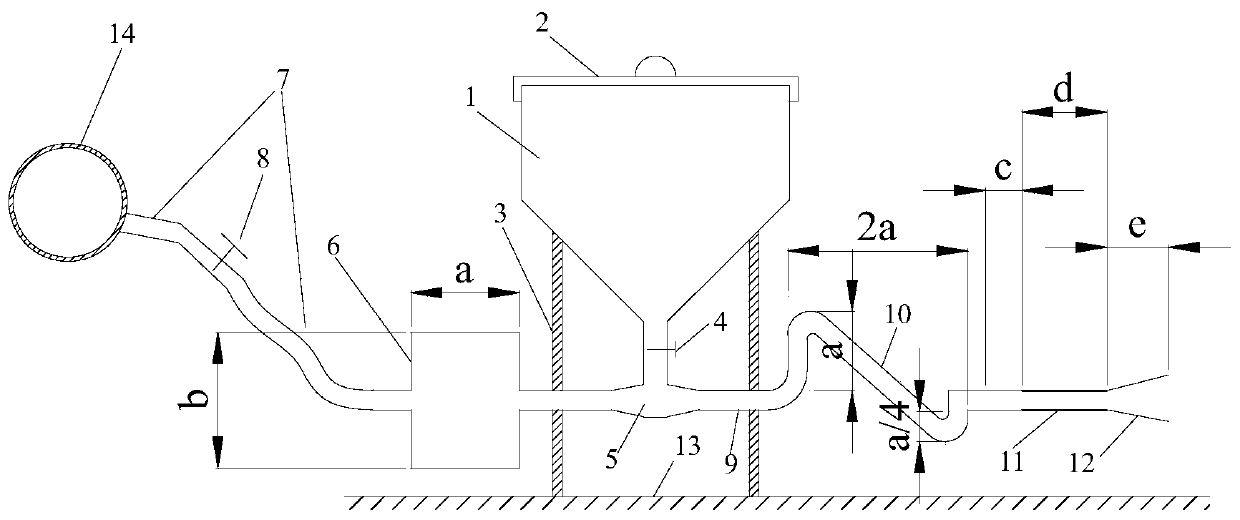

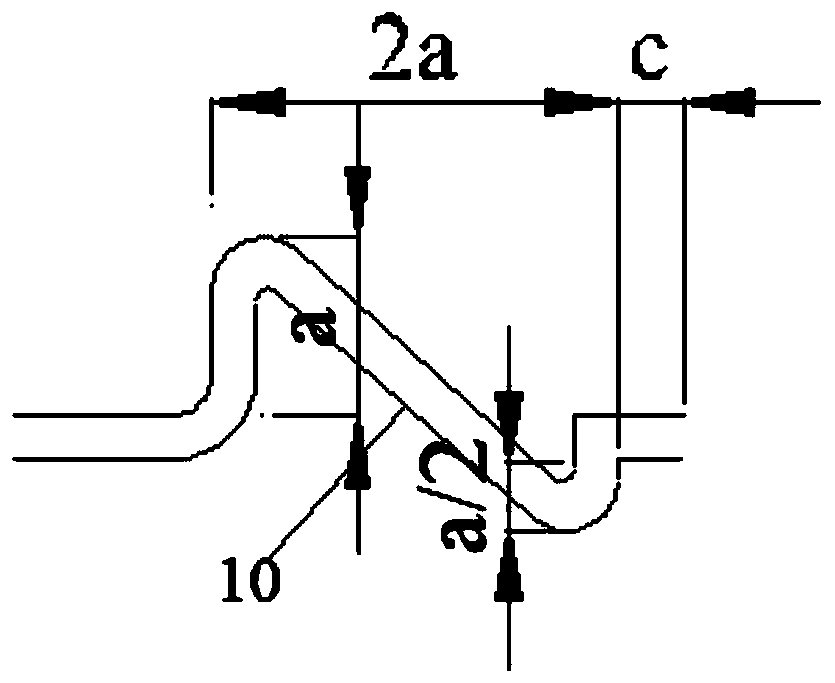

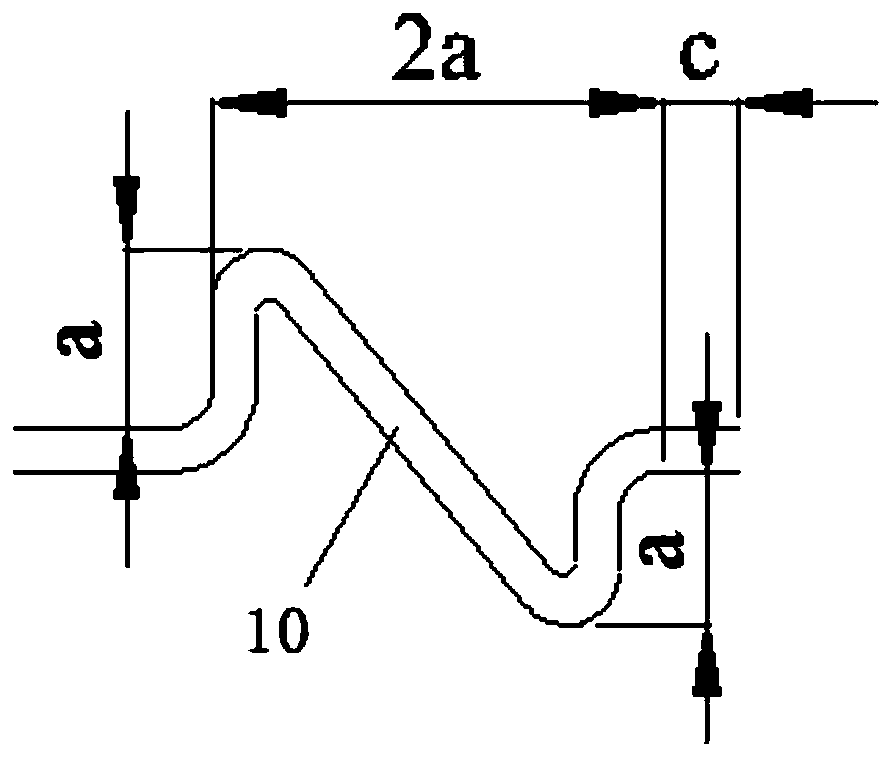

[0041] See attached picture.

[0042] A device for automatically spraying powdery fireproof materials to the rear of a fully mechanized mining support in a coal mine, comprising a feed hopper 1 installed on a fully mechanized mining support in a coal mine, a spraying storage bin 5, a pressure regulating chamber 6 and a discharge spoiler 10, The spray storage bin 5 is located below the feed hopper 1 and communicates with the discharge port at the bottom of the feed hopper 1, and the connected part is equipped with a feed regulating valve 4. One side of the spray storage bin 5 passes through the pipeline and the pressure regulating chamber. The air outlet of 6 is connected, and the other side is connected with the feed end of the discharge spoiler pipe 10 through the pipeline; The air outlet of 14 is connected; the discharge end of the discharge spoiler pipe 10 is connected with the nozzle 12 through the pipeline.

[0043]The pipeline connected between the air outlet of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com