Profile continuous automatic cleaning machine

An automatic cleaning machine and a technology for profiled materials, which are applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of low cleaning quality and low cleaning efficiency, and ensure cleaning Fast cleaning and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

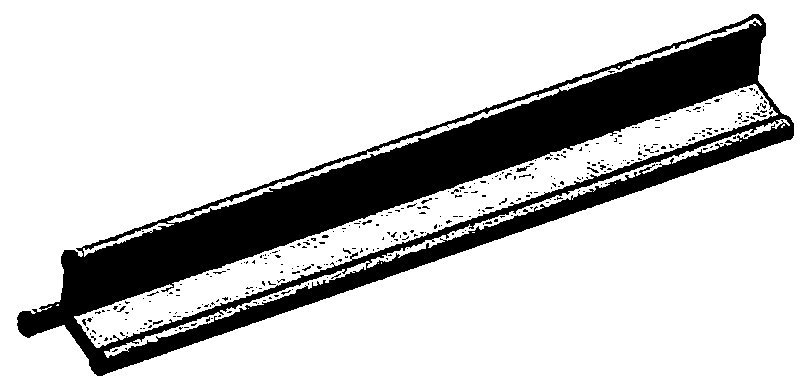

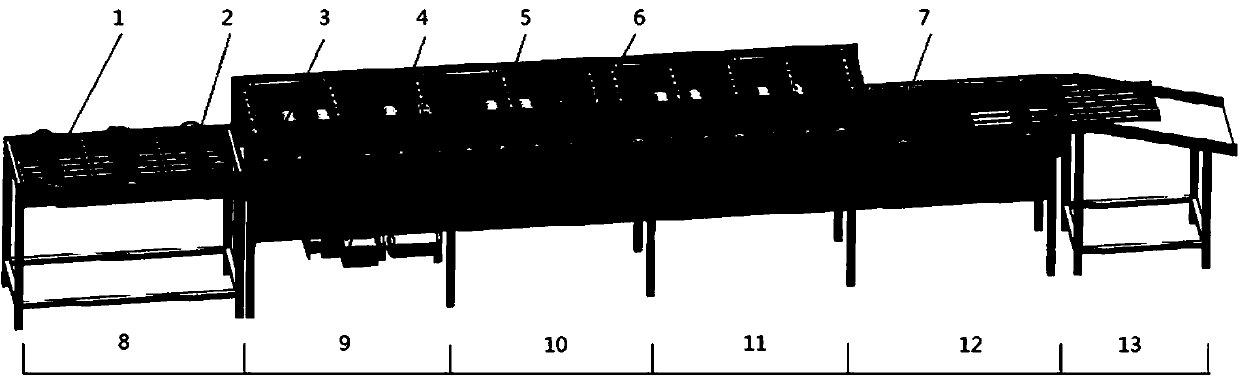

[0018] The profiled material continuous automatic cleaning machine provided by the present invention is successively divided into six parts: feeding area 8, washing liquid scrubbing area 9, clear water scrubbing area 10, high-pressure water washing area 11, drying area 12 and collecting area 13. , including frame body (including controller) 7, drive roller 2, pressure roller 3, gear motor 4, pipeline and nozzle 5, transmission device 6, brush 14, among which the workpiece (long profile) 1 is laid on On the sample feeding plate in the feeding area 8, the deceleration motor 4 drives the driving roller 2 to drive the workpiece (long profile) 1 to move horizontally after the speed is reduced. Scrub the workpiece (long profile) 1 in the cleaning solution pool of the liquid scrubbing area 9, and then the workpiece (long profile) 1 enters the clear water pool in the clean water scrubbing area for scrubbing, and is washed and dried by high-pressure water in the high-pressure water rins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com