Concrete test block production line

A concrete test block and production line technology, which is applied in the direction of manufacturing tools, ceramic molding workshops, supply devices, etc., can solve the problems of low production efficiency and heavy physical labor of workers, and achieve high production efficiency, liberation of physical labor, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

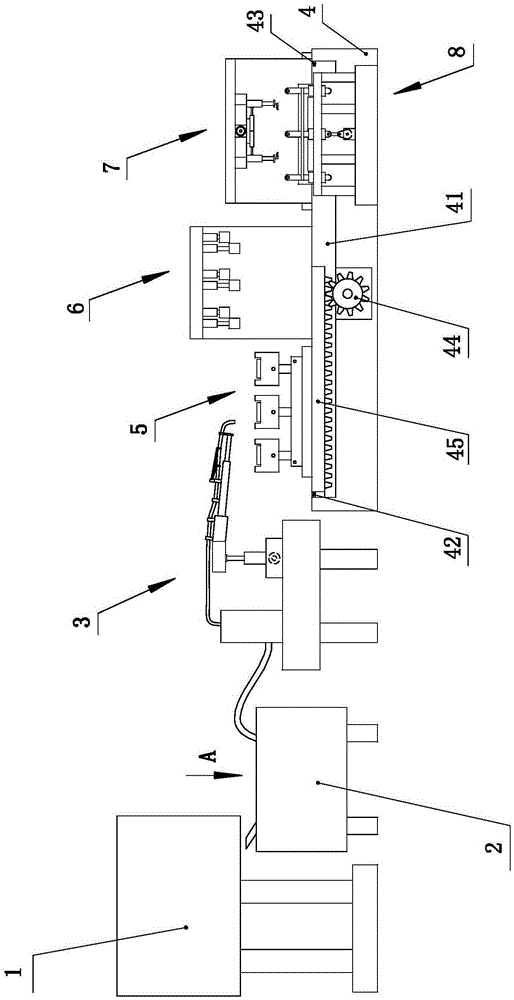

[0047] Such as Figure 1 to Figure 22 As shown, according to the processing process of the test block, the present invention includes a mixer 1, a storage tank 2, a concrete injection assembly 3, a track 4, a mold assembly 5, a compacting assembly 6, a handling assembly 7, and a form removal assembly 8 and vibrating table 9, the present invention will be described below in conjunction with accompanying drawing.

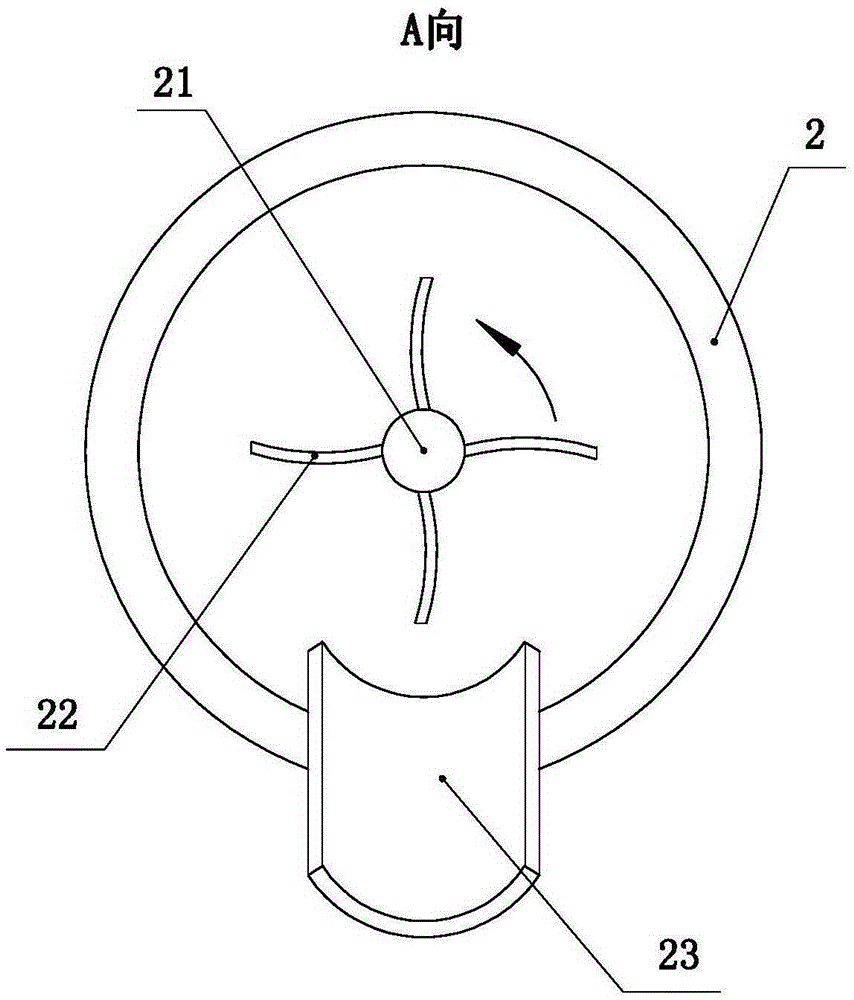

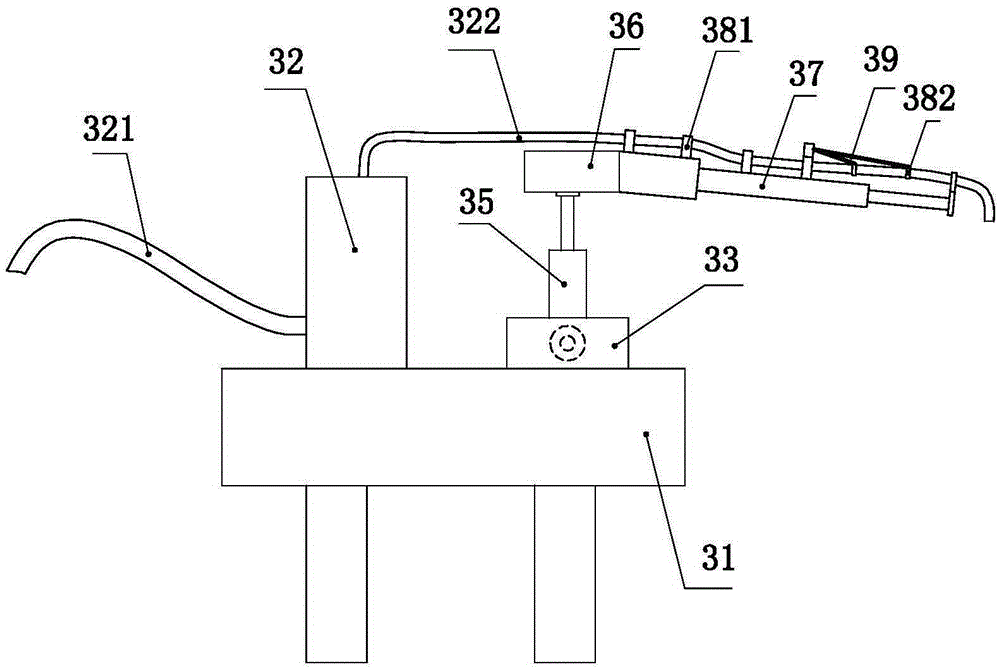

[0048] Such as figure 1 As shown, the mixer 1 is used for mixing concrete, and a storage tank 2 is provided at the discharge end of the mixer. The storage tank is a circular metal piece, and the inner cavity of the storage tank is used to store the stirred concrete. Such as figure 2 As shown, in order to facilitate the concrete to fall into the storage barrel, an arc-shaped deflector 23 arranged obliquely is fixed on the storage barrel below the discharge end of the mixer, and the high end of the deflector is placed below the discharge end of the mixer. The lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com