A blowing-in-one foam board depowder machine

A technology of foam boards and racks, applied in the direction of removing smoke and dust, using gas flow cleaning methods, cleaning methods and appliances, etc., can solve the problems of dust residue on the surface of foam boards, to ensure cleanliness, avoid environmental pollution, The effect of improving quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

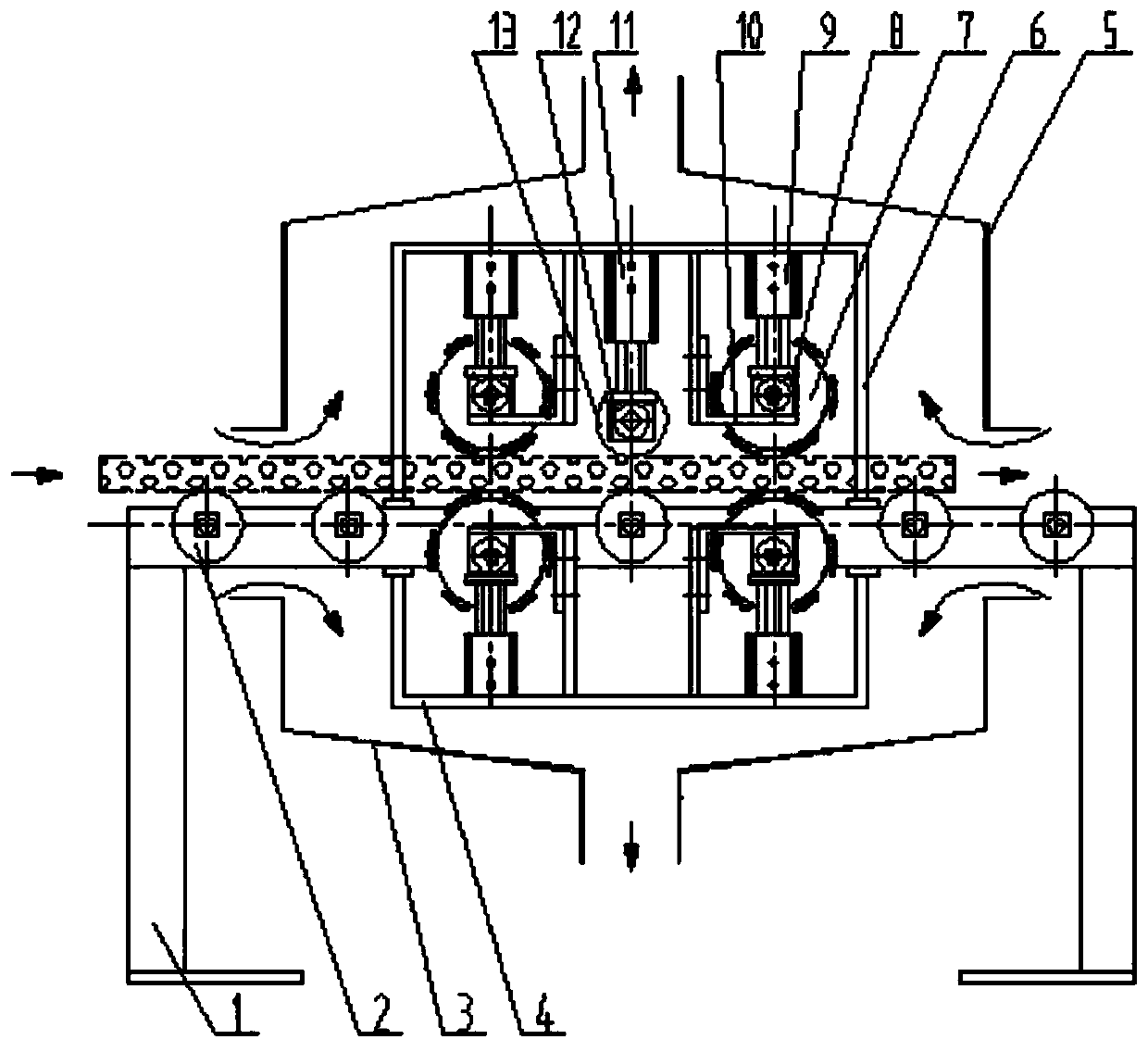

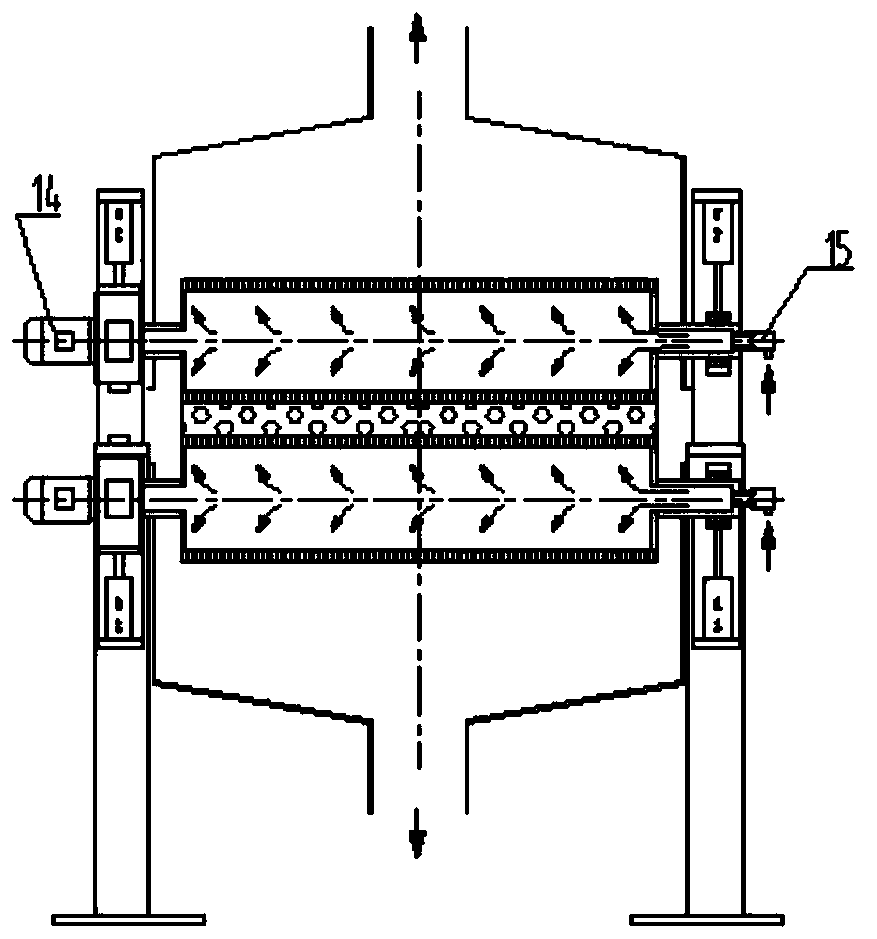

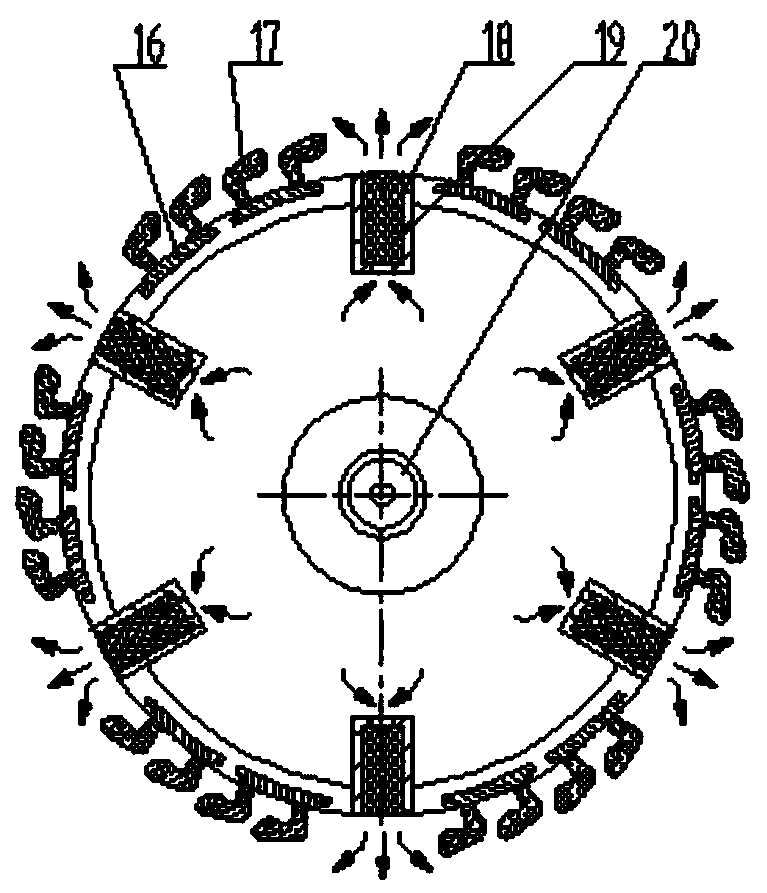

[0020] combine figure 1 , figure 2 and image 3 As shown, a blowing-in-one foam board depowder machine includes a frame 1, an electric roller 2, a lower dust cover 3, a lower bracket 4, an upper dust cover 5, an upper bracket 6, a blower Sweeping roller 7, blowing bearing with seat 8, blowing cylinder 9, adjustable limit plate 10, pressing cylinder 11, pressing bearing with seat 12, pressing roller 13, motor reducer 14, rotary joint 15, all The blowing roller 7 includes a roller body 16 , a brush 17 , a nozzle seat 18 , a filter nozzle 19 , and a journal 20 . Described electric roller 2 is arranged on frame 1, and frame 1 two sides are respectively fixed with upper bracket 6 and lower bracket 4, and upper bracket 6 and lower bracket 4 each have 2 pieces, are gantry structure form. Described adjustable limit plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com