High-speed indexing separator

A divider, high-speed technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problems of limiting the rotation speed of the divider, high heat of the divider, affecting the service life and safety of the divider, etc. The effect of sliding friction, reducing damage and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

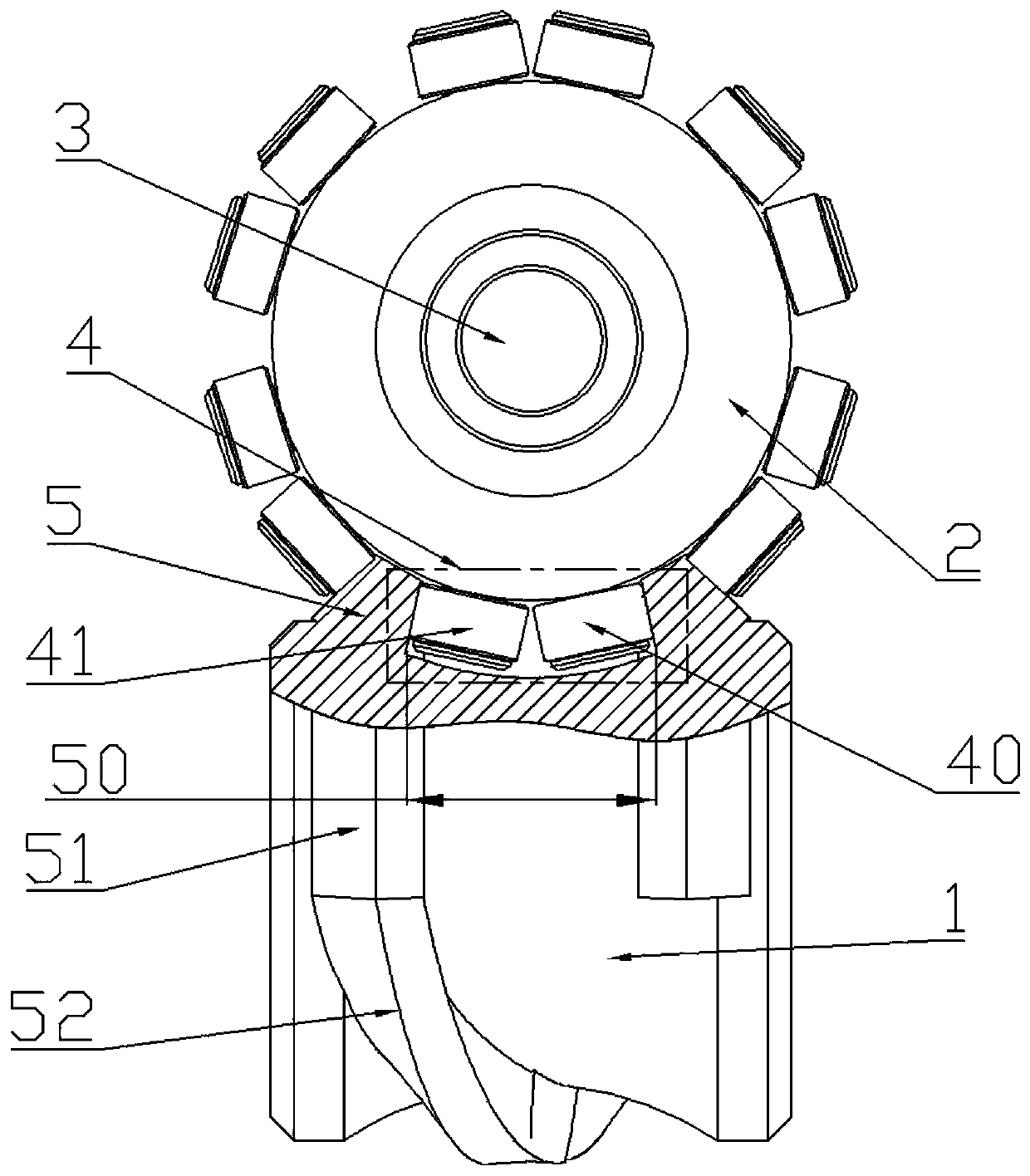

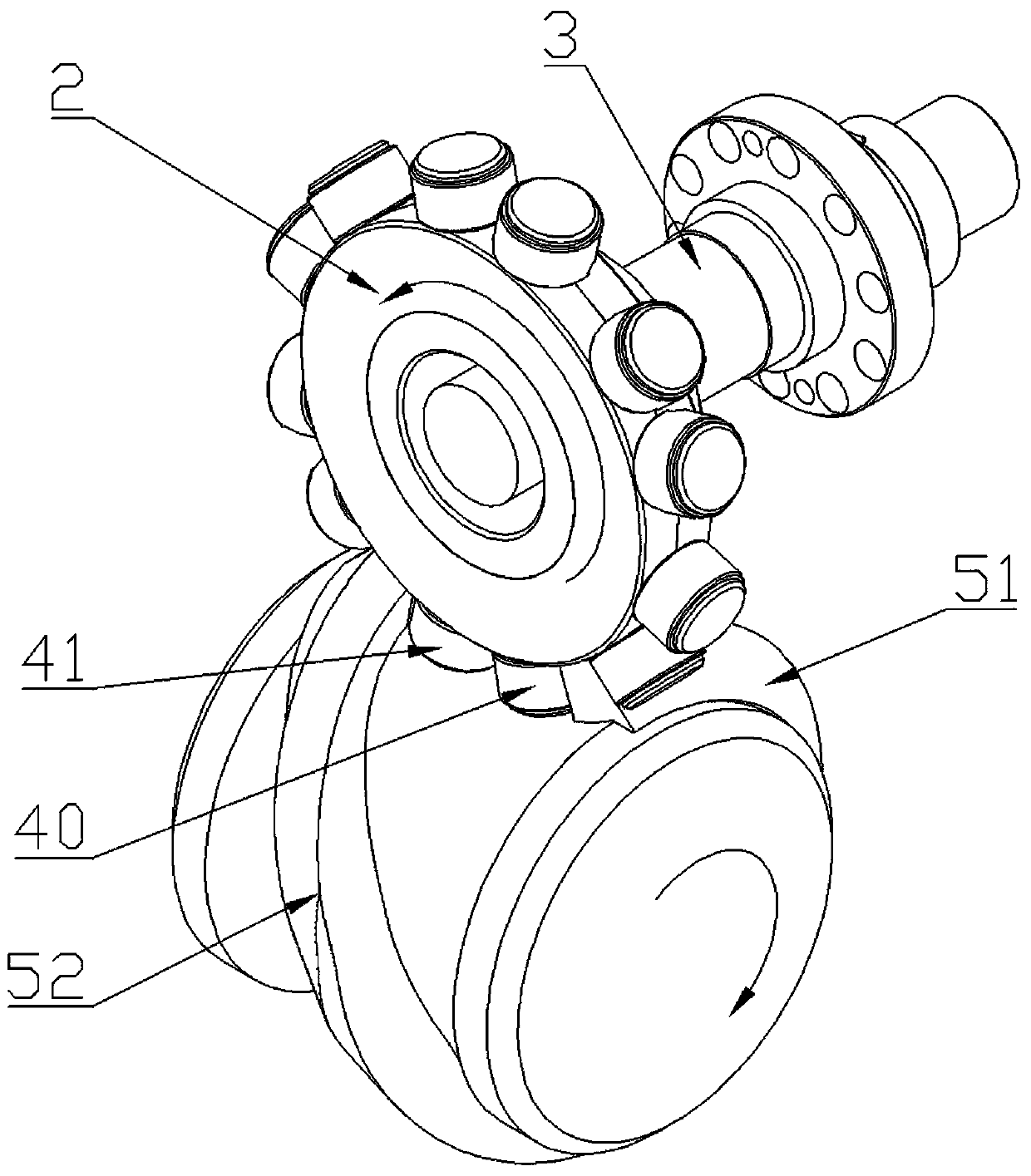

[0018] The high-speed intermittent divider described in this embodiment, such as figure 1 As shown, it includes an input cam 1, an output turret 2 and an output shaft 3, the input cam 1 is in transmission connection with the output turret 2, and the output turret 2 is in transmission connection with the output shaft 3; the output turret 2 A plurality of roller pairs 4 are distributed radially around, and the roller pairs 4 include positive rotation rollers 40 and reverse rotation rollers 41 with the same structure, and the input cam 1 is provided with a supporting rib with a driving curve profile 5. When the input cam 1 and the output turret 2 cooperate with each other, the roller pair 4 is located in the gap 50 formed by the surrounding distribution of the support rib 5, and the forward rotation roller 40 and the reverse rotation roller 41 of the same roller pair 4 are respectively The faces of the support ribs 5 on both sides of the gap 50 are in contact with each other, and...

Embodiment 2

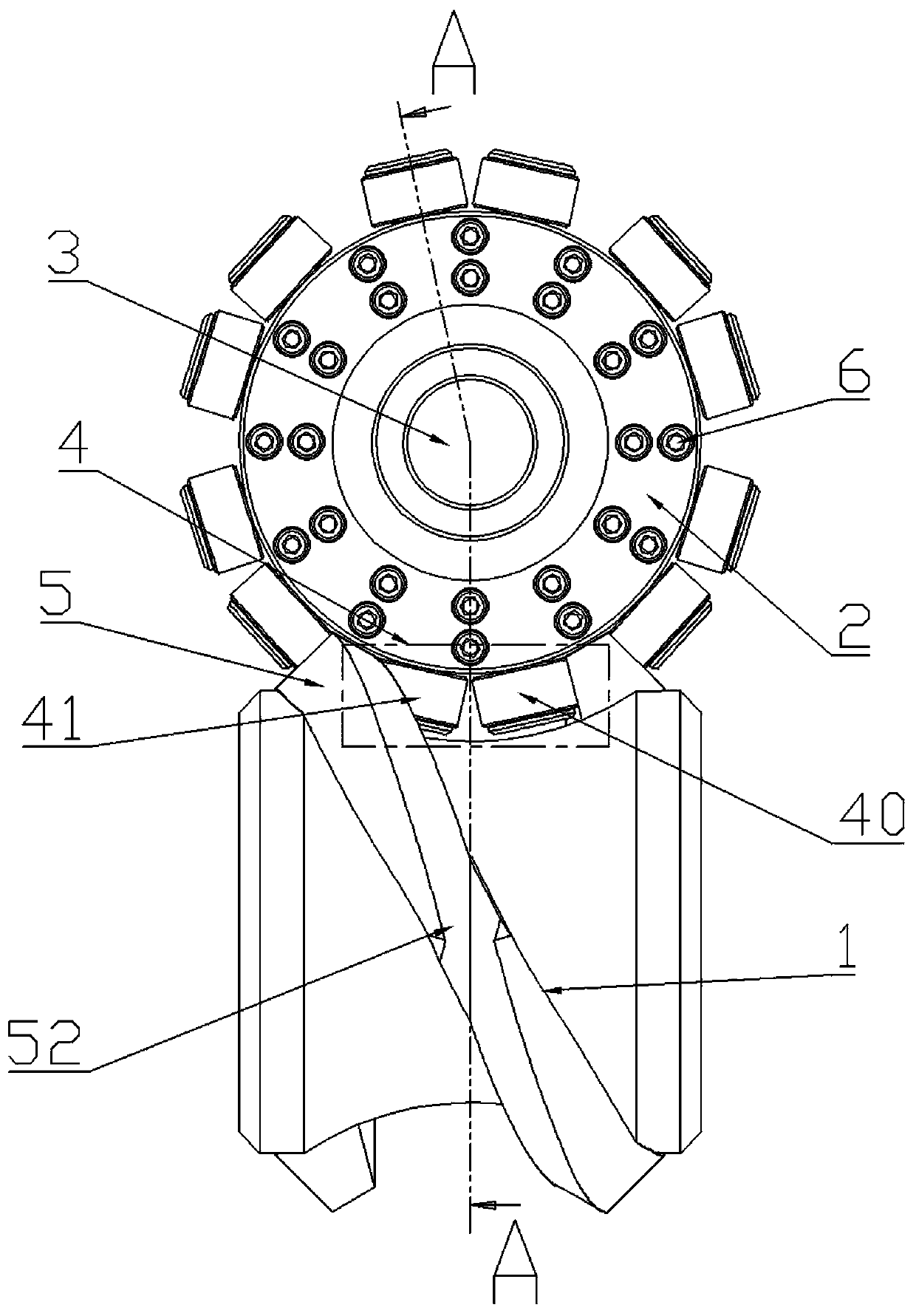

[0023] The high-speed intermittent divider described in this embodiment, such as image 3 , Figure 5 As shown, in addition to the features described in Embodiment 1, in order to facilitate installation and processing, the output turret includes a rotary roller seat 20 and an end cover 21, and the rotary roller seat 20 is connected to the output shaft through transmission. The center of the roller seat 20 is provided with a boss 200, and the center of the end cover 21 is provided with a positioning hole 210. The positioning hole 210 is matched with the boss 200 for positioning, and the end cover 21 is fixedly connected with the rotary roller seat 20. Radial grooves 201 are distributed around the platform 200, and one side of the end cover 21 is provided with auxiliary grooves 211 corresponding to the radial grooves 201, such as Figure 4 , Figure 5 As shown, the radial groove 201 and the auxiliary groove 211 form a plurality of mounting holes 23, and the forward roller 40 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com