Composite insulating material breakdown experimental device and experimental method

A technology of composite insulation and experimental equipment, which is applied in the direction of measuring equipment, instruments, measuring electricity, etc., can solve the problems of damage to insulation structure, composite insulation sleeve fracture, breakdown accidents, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0017] Example: The experimental platform and experimental method for the breakdown of composite insulating material FRP barrel flakes under the conditions of high pressure, constant humidity and constant temperature include the following steps:

[0018] The first step: build the experimental platform

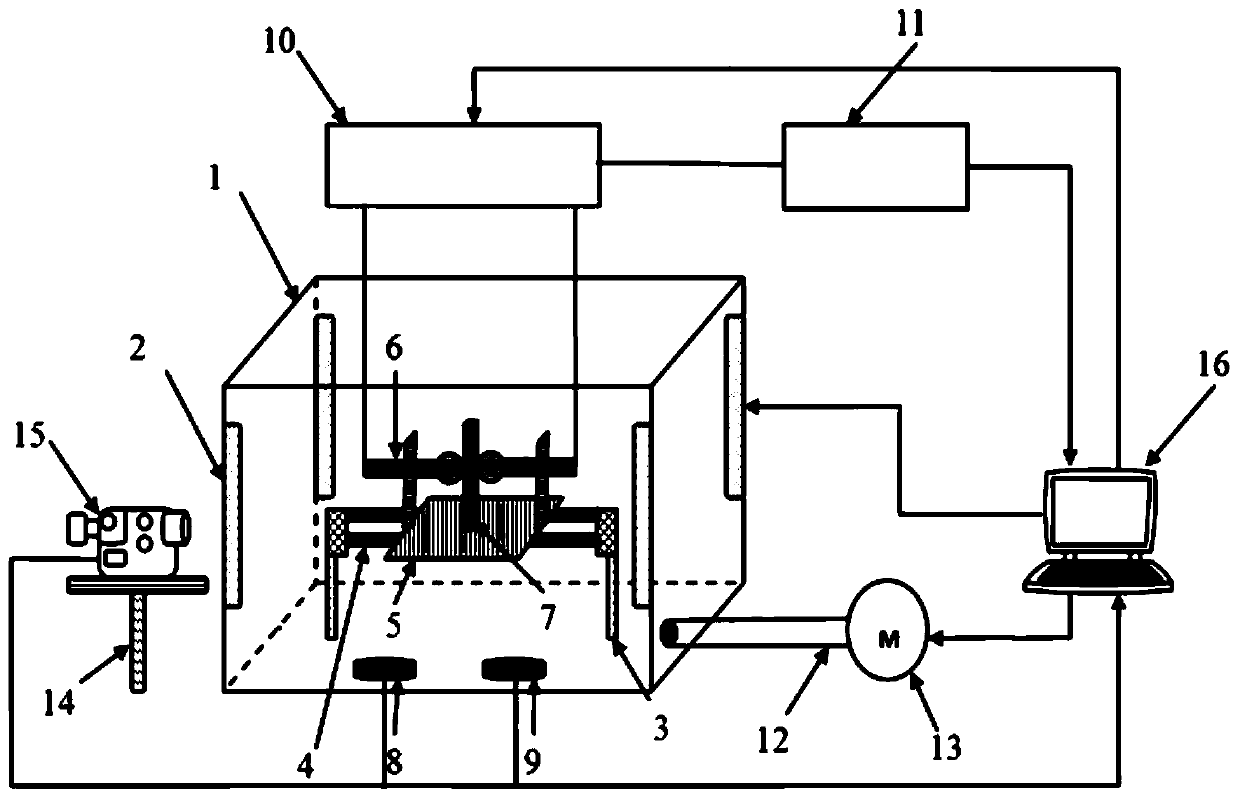

[0019] Build an experimental platform for the breakdown of composite insulating material glass fiber reinforced plastic barrel slices under the conditions of high pressure, constant humidity and constant temperature. There are 4 heating tubes 2 inside the transparent aging box 1, and the heating tubes 2 are connected to the computer 16 to receive the computer 16. Control commands sent. Connect the fixed spherical copper electrode 6 to the external circuit 10, connect the voltage measuring instrument 11 to the computer 16, and receive the control instructions sent by the computer 16 at the same time. The temperature sensor 8 and the humidity sensor 9 are installed, and the temp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap