Main pump maintenance and simulation training device

A simulation training and pump shaft technology, which is applied to the simulation device, simulator, teaching model and other directions of space navigation conditions, can solve the problem that there is no simulation training for maintenance personnel, achieve the effect of improving skills and ensuring the quality of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

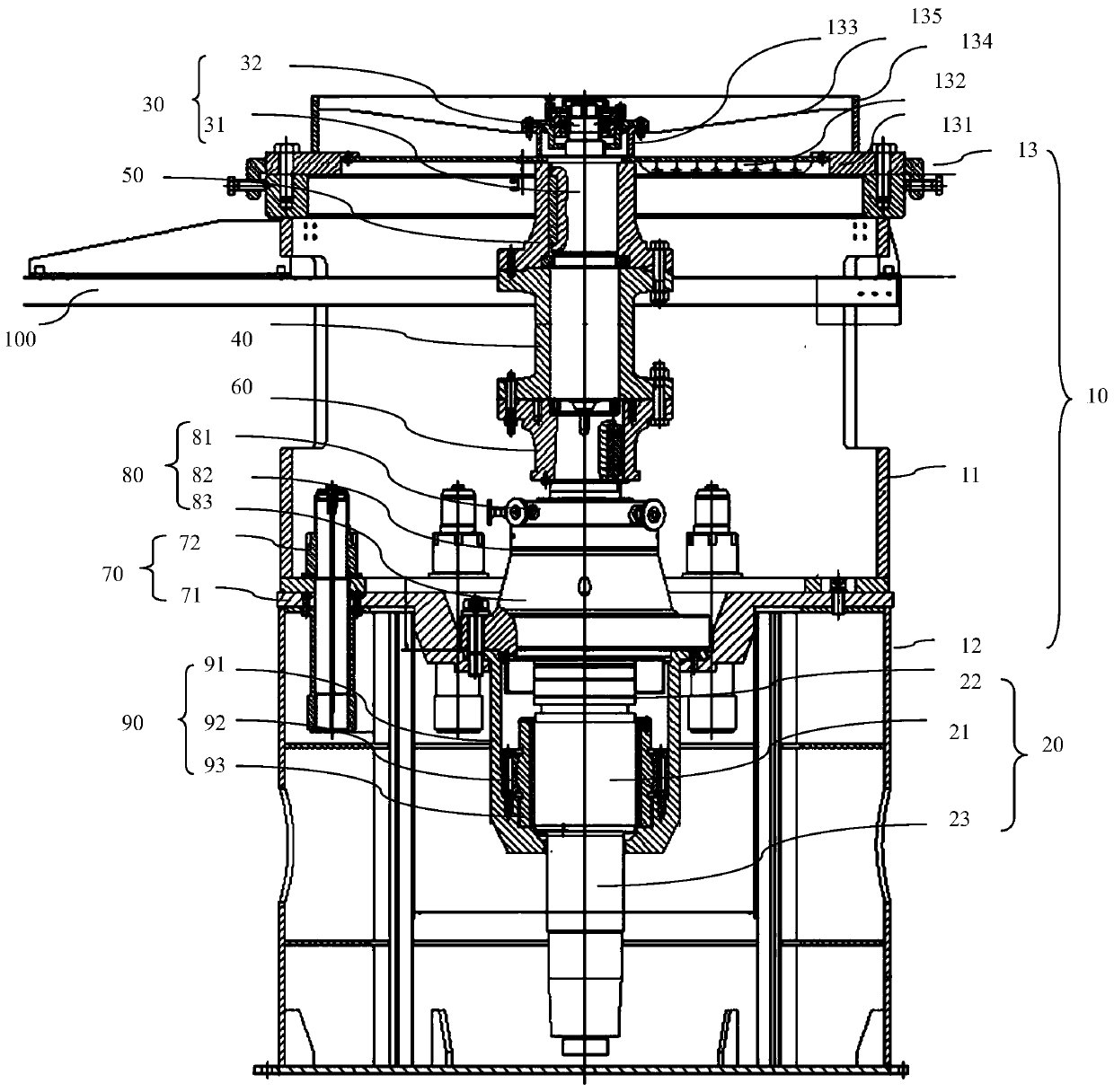

[0040] figure 1 A preferred embodiment of the main pump maintenance simulation training device of the present invention is shown. The main pump maintenance simulation training device is based on the 100D main pump as a prototype, developed through optimization and improved design, and is mainly deployed around the pump shaft. It can simulate the structure and size of the 100D main pump in an all-round way. The disassembly process and the use of special tools for disassembly and assembly are basically the same as those of the 100D main pump maintenance activities. It can be used by maintenance personnel to carry out 2C maintenance and 4C maintenance of the main pump. Maintenance training drills to improve the skills of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com