Electrical connector

A technology of electrical connectors and connectors, which is applied in the direction of connections, circuits, and parts of connection devices, can solve problems such as poor contact, easy crosstalk, and increased production costs, so as to reduce crosstalk, reduce manufacturing processes, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

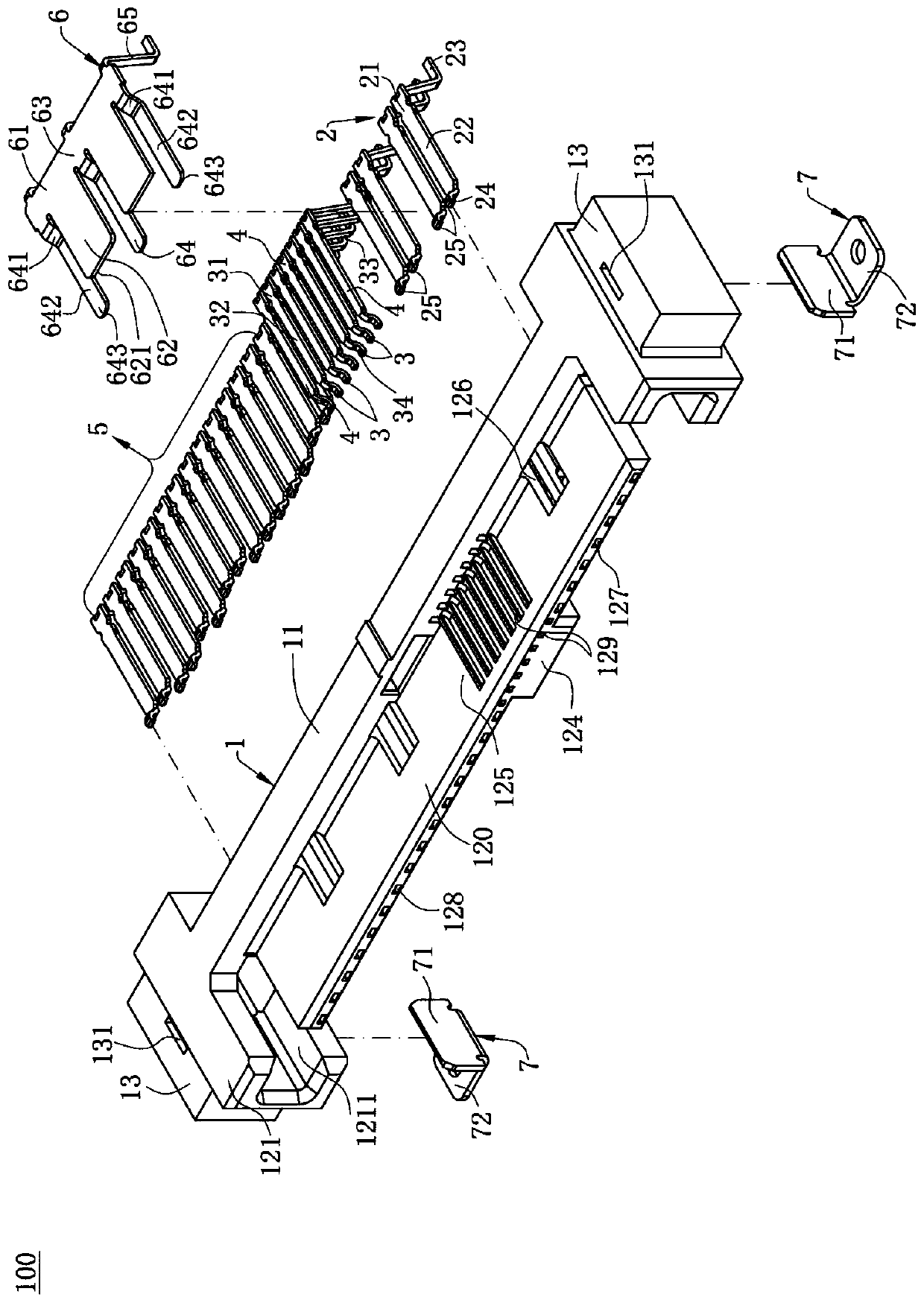

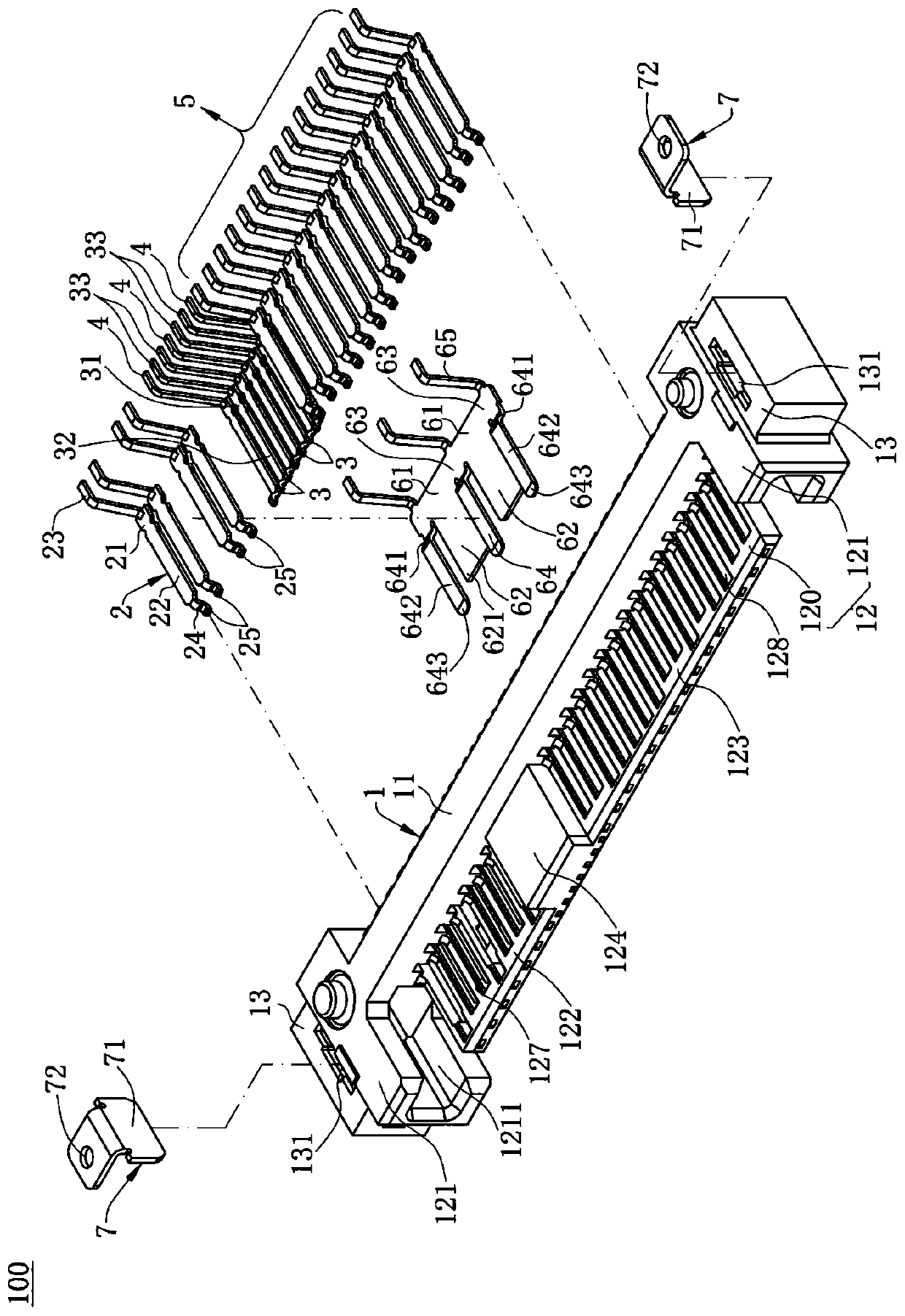

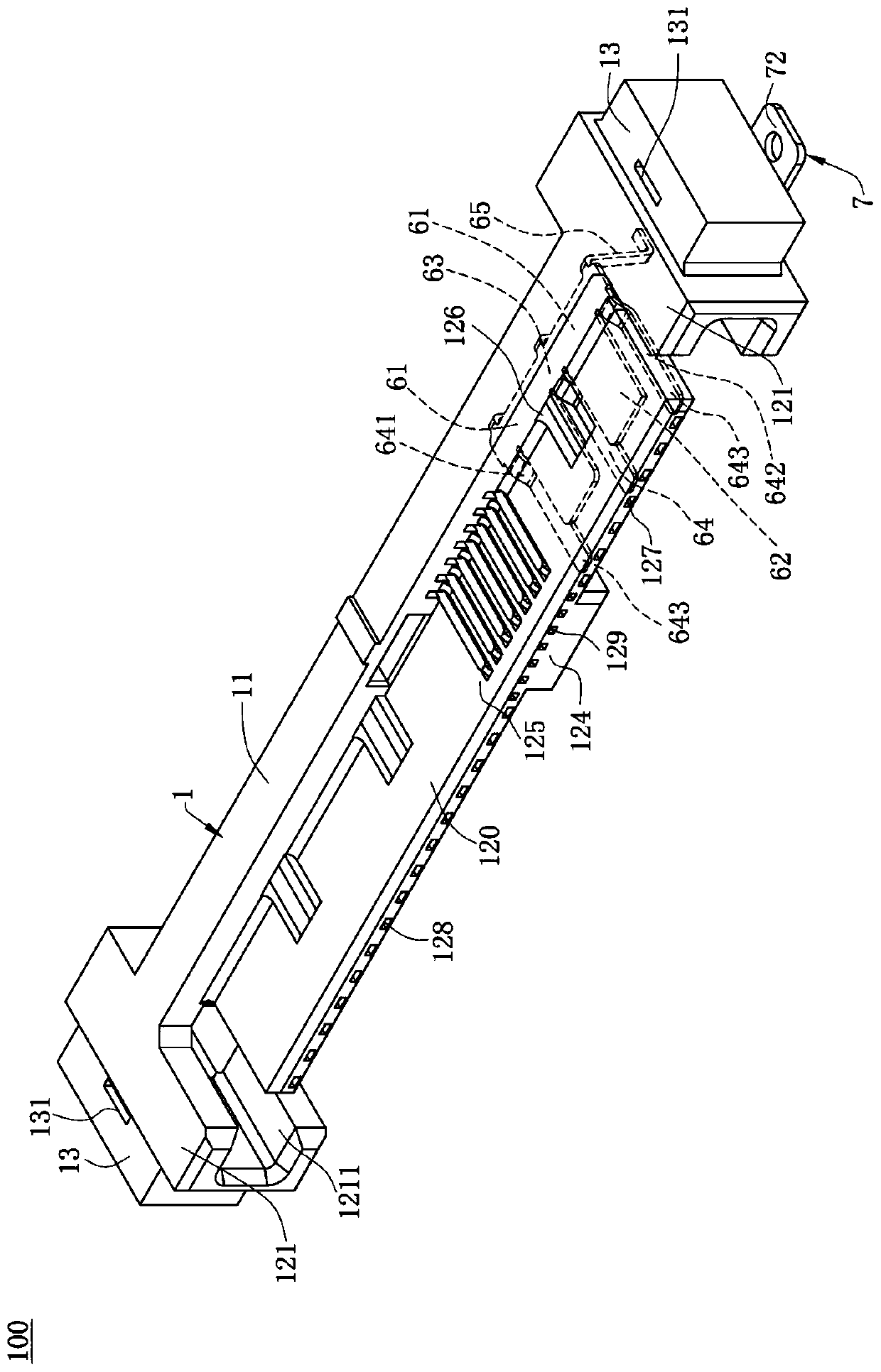

[0045] like figure 1As shown, the electrical connector 100 of the present invention is used for docking with a mating connector (not shown). The electrical connector 100 includes an insulating body 1, a plurality of first signal terminals 2, a plurality of second signal terminals 3, a plurality of grounding terminals 4, a plurality of power terminals 5 and a Shield 6. Two metal parts 7 are inserted on both sides of the insulating body 1, and the metal parts 7 are used to fix the insulating body 1 on a circuit board (not shown).

[0046] like Figure 1 to Figure 4 As shown, the insulative body 1 is elongated. The insulative body 1 includes a base 11 and a butt joint 12. The butt joint 12 includes a tongue 120 extending forwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com