A device for shelling half-shelled mussels

A thick-shelled mussel and cutting device technology, which is applied in bivalve processing, crustacean processing, slaughtering, etc., can solve the problems of heavy workload, a large amount of manpower, and low efficiency, so as to improve the shell opening effect, improve efficiency, The effect of saving manpower and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

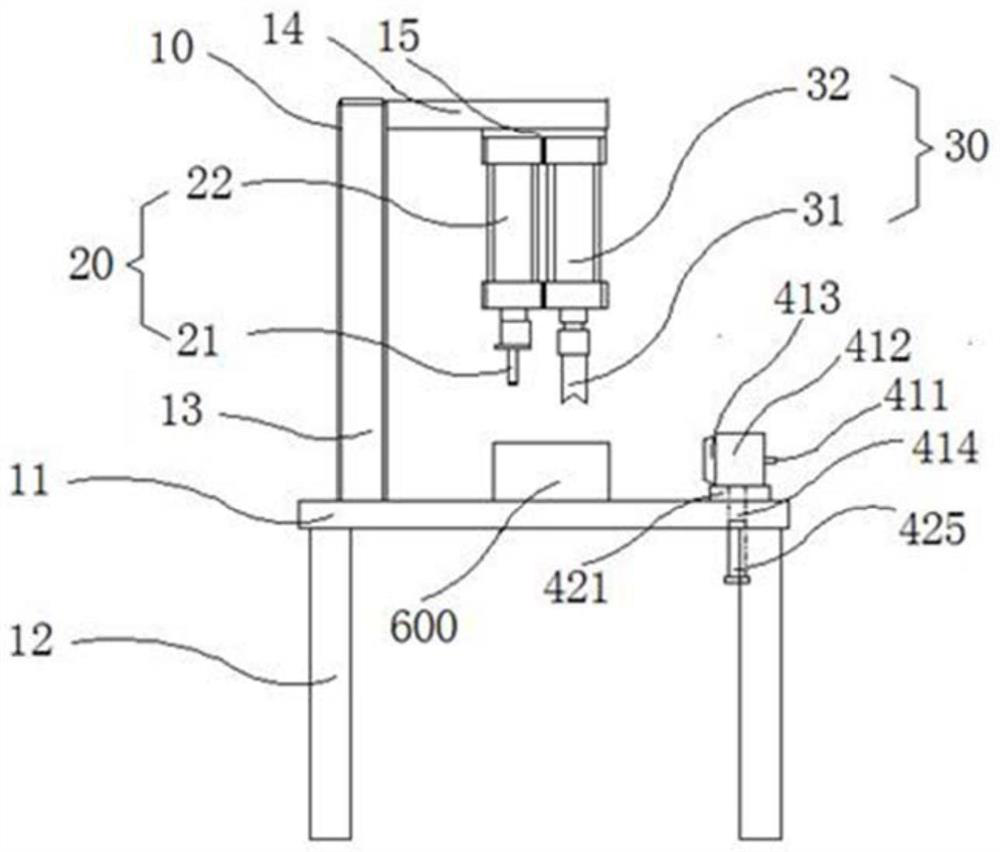

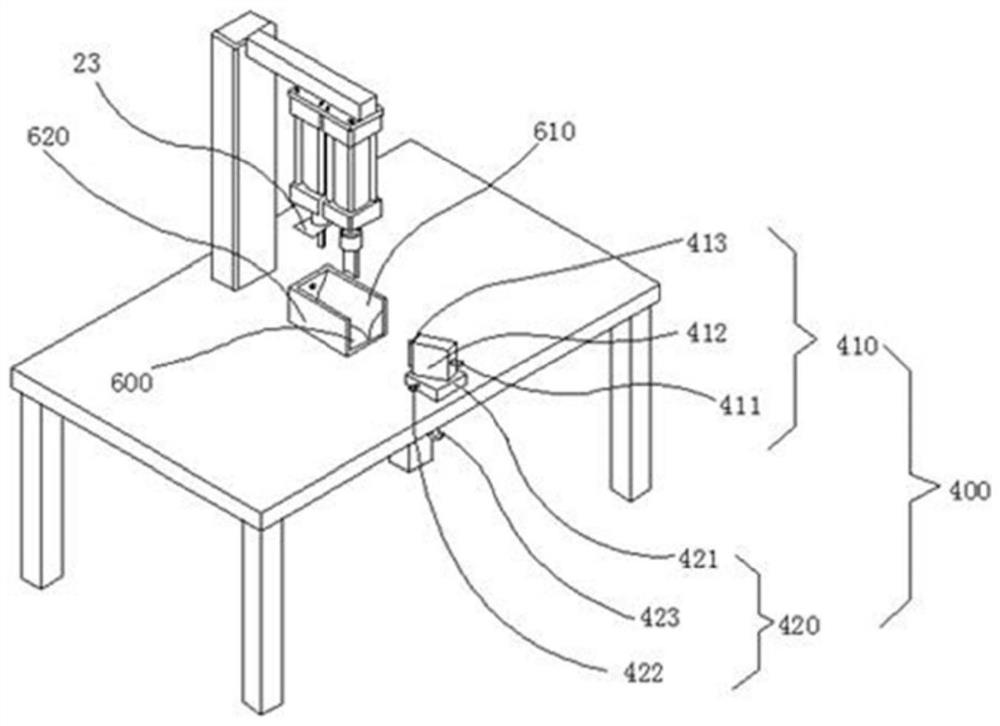

[0052] In this embodiment, if figure 1 , figure 2 As shown, a thick shell mussel is provided with a processing stage 10, and the processing table 10 includes a processing desktop 11 and four processing plashed legs 12 respectively connected to the processing desktop 11-angle, and the processing table 11 side connection With the support arm 13, the support arm 13 is disposed at the processing table 11, the top of the support arm 13 is connected to the single-habitlet 14, and the spinning arm 14 is provided on the single-habitlet 14, and the air pressure cylinder connection plate 15 is provided with a connection threaded hole through the screw. The fixed manner is fixed to the support arm vertically.

[0053] The wedge cutter 21 is provided with a cylindrical hole inserted into the cylindrical hole by an interference fit, and the wedge-shaped tool gas pressure cylinder 22 is connected to the wedge cutter 21; in the design of the wedge cutter 31 and the cylindrical hole There is a sq...

Embodiment 3

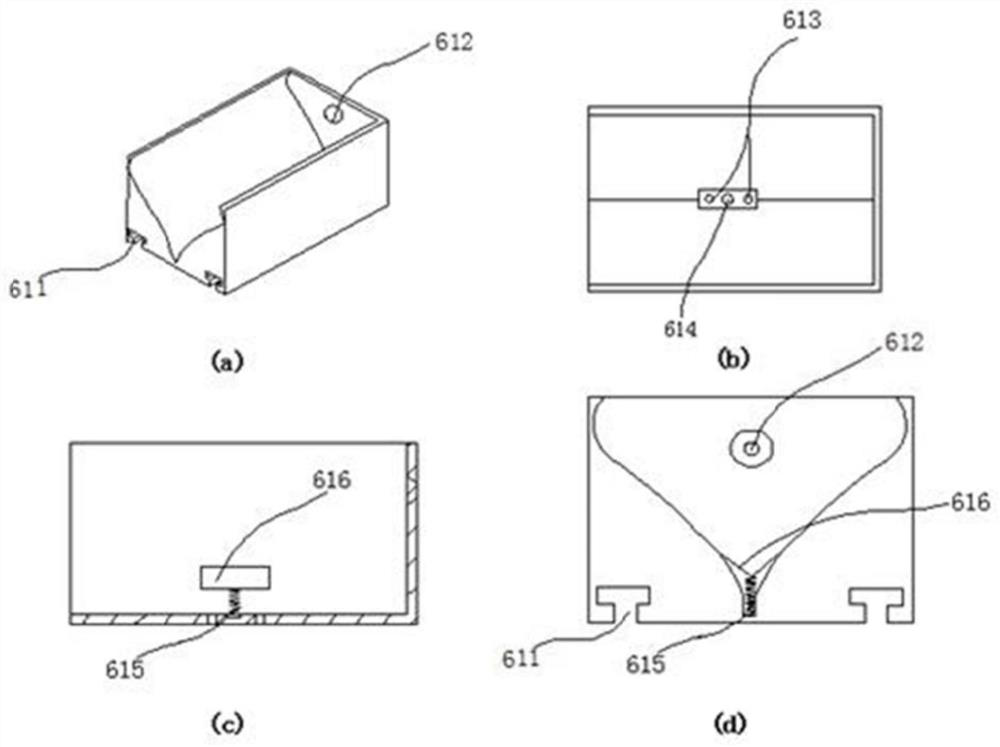

[0070] A thick shell muscle derived semi-shell device includes a thick shell mussels, and the thick shell mussel is placed in thick shell mussels 600 when the thick shell mussel starts working. , Place the thick shell mussel back, and the abdomen is placed upward, and the top of the thick shell mussels are placed in the thick-shell mussel fixed table 610 rear end face 612, the maximum aperture according to the concave hole 612 The thickness of the thick shell mussel mesh is set, and the maximum pore diameter of the concave hole 612 is 35mm; the control system of the control system first controls the two-bit five-way solenoid valve 551 in the energization state, thereby controlling the piston of the wedge-shaped tool pressure cylinder 22 to start intake sports. The wedge-shaped cutter 21 of the wedge-shaped tool pressure cylinder 32 is driven, and the wedge-shaped cutter 21 cuts the housing along the thick shell, the thick shell mussel, and realizes the thick shell mussel from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com