Automatic feeding machine and intermittent conveyor for clothes hanger sanding machine

A technology of automatic feeding machine and sanding machine, which is applied to the parts of grinding machine tools, grinding feed movement, grinding/polishing equipment, etc. It can solve the problems of no automation, low efficiency, and damage to the health of production line workers. Achieve the effects of easy maintenance, guaranteed sanding time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the examples.

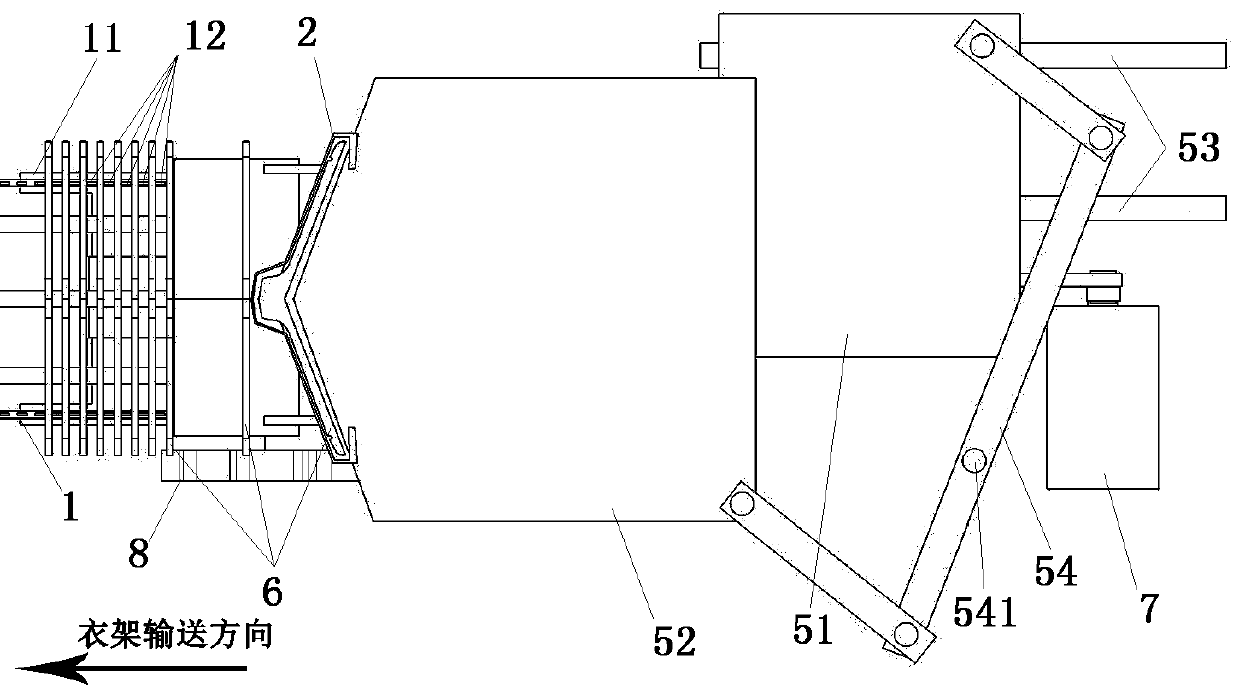

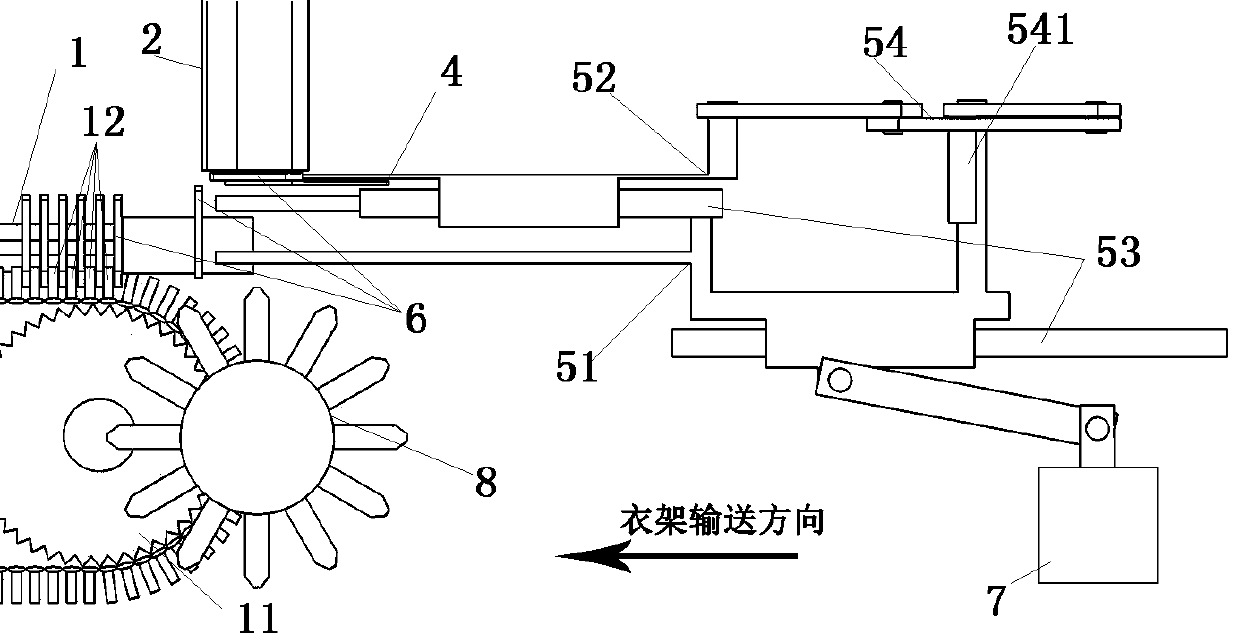

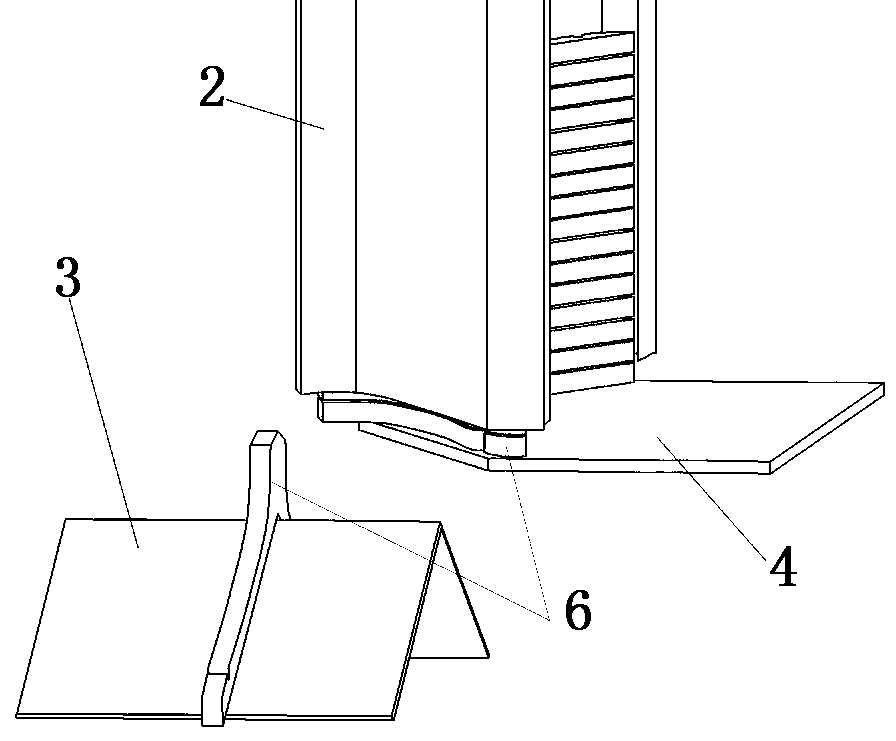

[0023] An intermittent conveyor used for a clothes hanger sander, comprising a sprocket conveyor 1, along the conveying chain of the sprocket conveyor 1, a limit riser 12 is arranged, and the clothes hanger is sandwiched between the limit risers 12 during operation , including the automatic feeder installed behind the sprocket conveyor, see figure 1 and figure 2 The automatic feeding machine includes a feeding hopper 2 installed on the frame, a ridge-shaped guide plate 3, a receiving plate 4, and a material pushing device 5. The feeding hopper 2 is arranged vertically in a columnar shape, and the horizontal section of the inner wall of the feeding hopper is connected to 6 hanger blanks. The contours of the top, shoulder and both ends are adapted. When the hanger blank is placed horizontally in the feeding hopper 2 with the head facing forward, the hanger blank 6 is restricted b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com