Auxiliary frame with connection adapter

A technology for auxiliary frames and adapters, which is applied to vehicle components, substructures, motor vehicles, etc., and can solve the problems of increasing vehicle manufacturing and assembly work and cost expenditures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

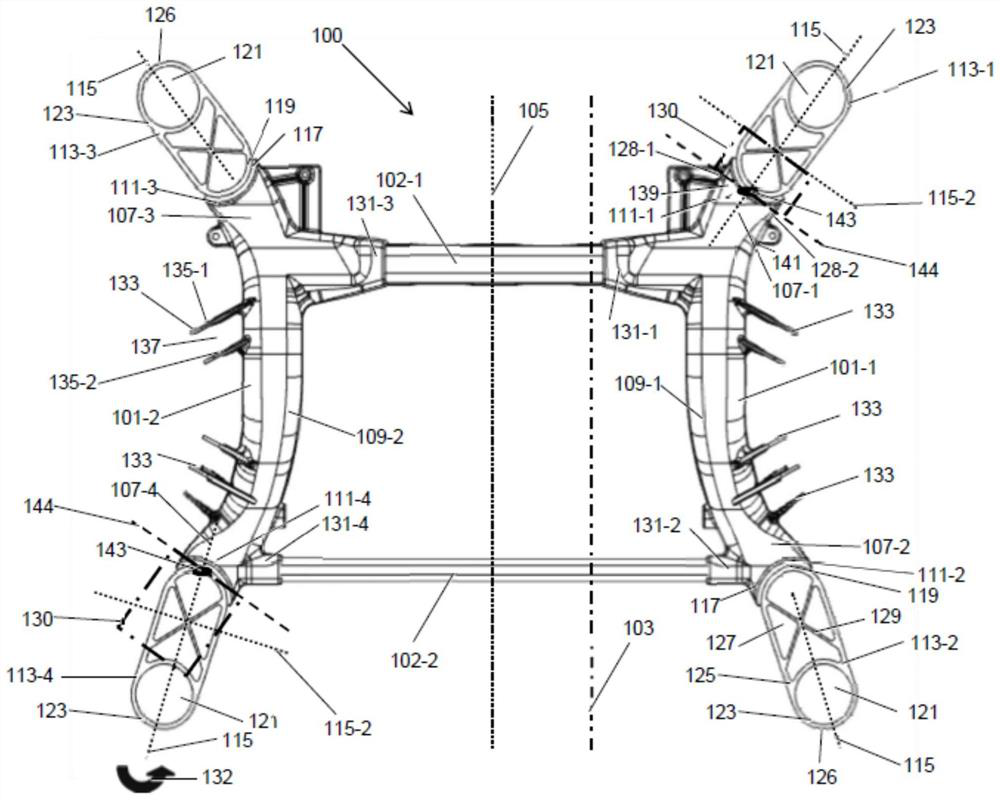

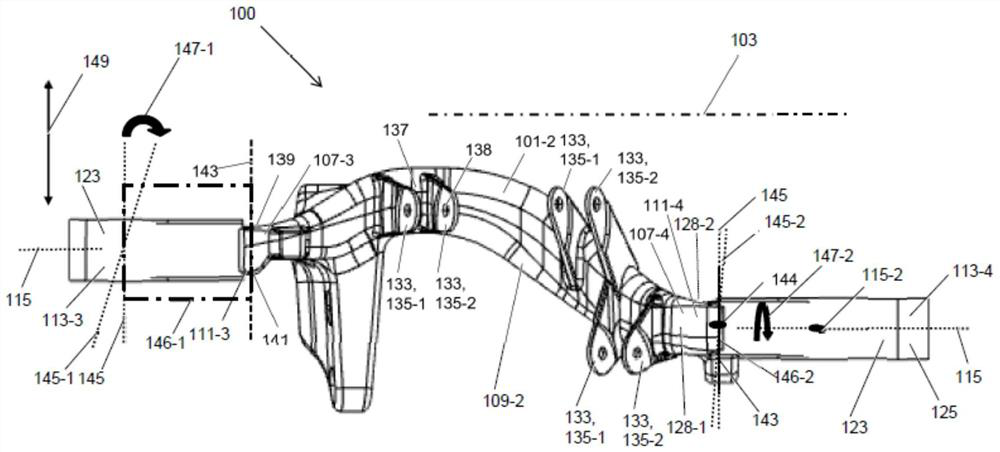

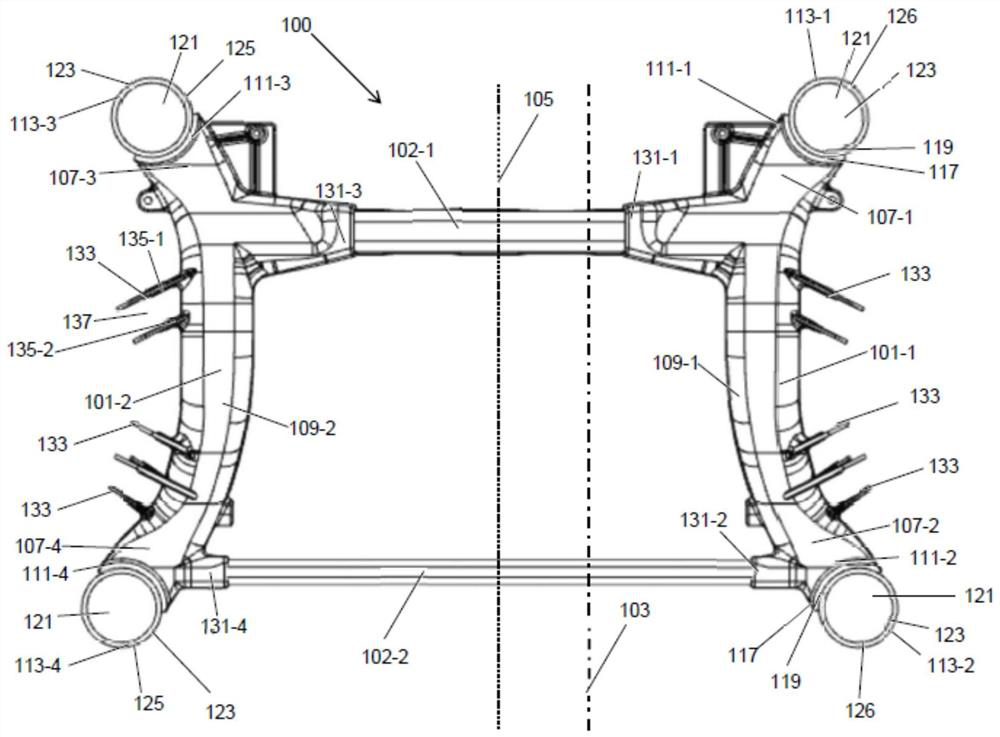

[0143] figure 1 A perspective view of the auxiliary frame 100 according to the first embodiment is shown. The subframe 100 is used in a vehicle and is operatively connected to the vehicle frame. Furthermore, the auxiliary frame 100 allows connection of a running gear assembly, such as running gear components. The connection between the auxiliary frame 100 and the vehicle frame can be achieved by independent mounting (eg, through a flexible mount) or dependent mounting (eg, through threaded joints). By independent mounting (e.g. via a flexible base), effective vibration isolation can be achieved, potentially reducing the resulting noise. A stable connection between the auxiliary frame 100 and the vehicle frame can be achieved by dependent mounting (for example, by screw joints).

[0144] figure 1 The auxiliary frame 100 shown in has a longitudinal member 101-1 and a second longitudinal member 101-2 and a first beam 102-1 and a second beam 102-2. In this structure, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com