Labeling device and production line

A labeling and labeling head technology, applied in the direction of labeling, labeling machines, labels, etc., can solve problems such as large volume, influence of production line structure, and large changes in production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

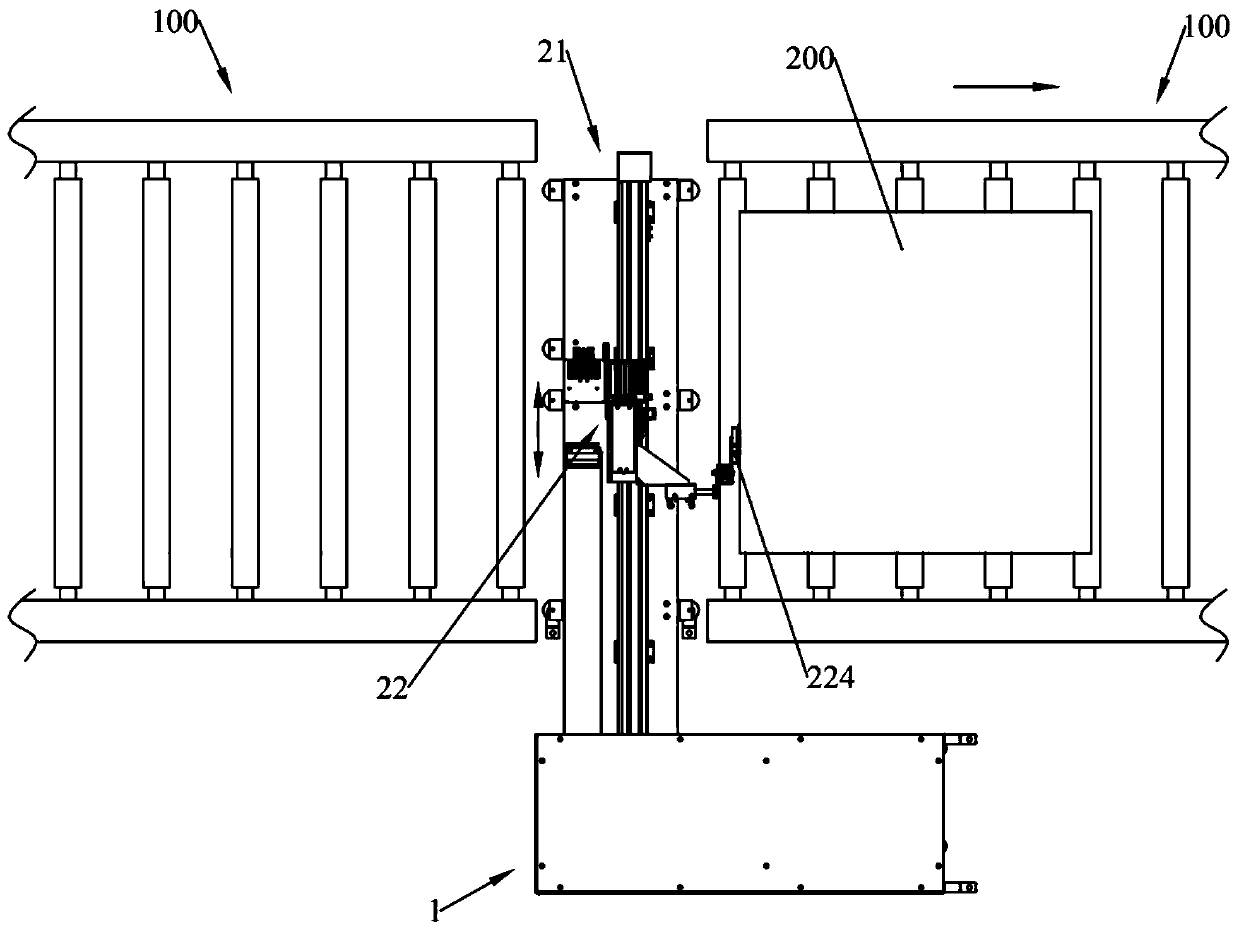

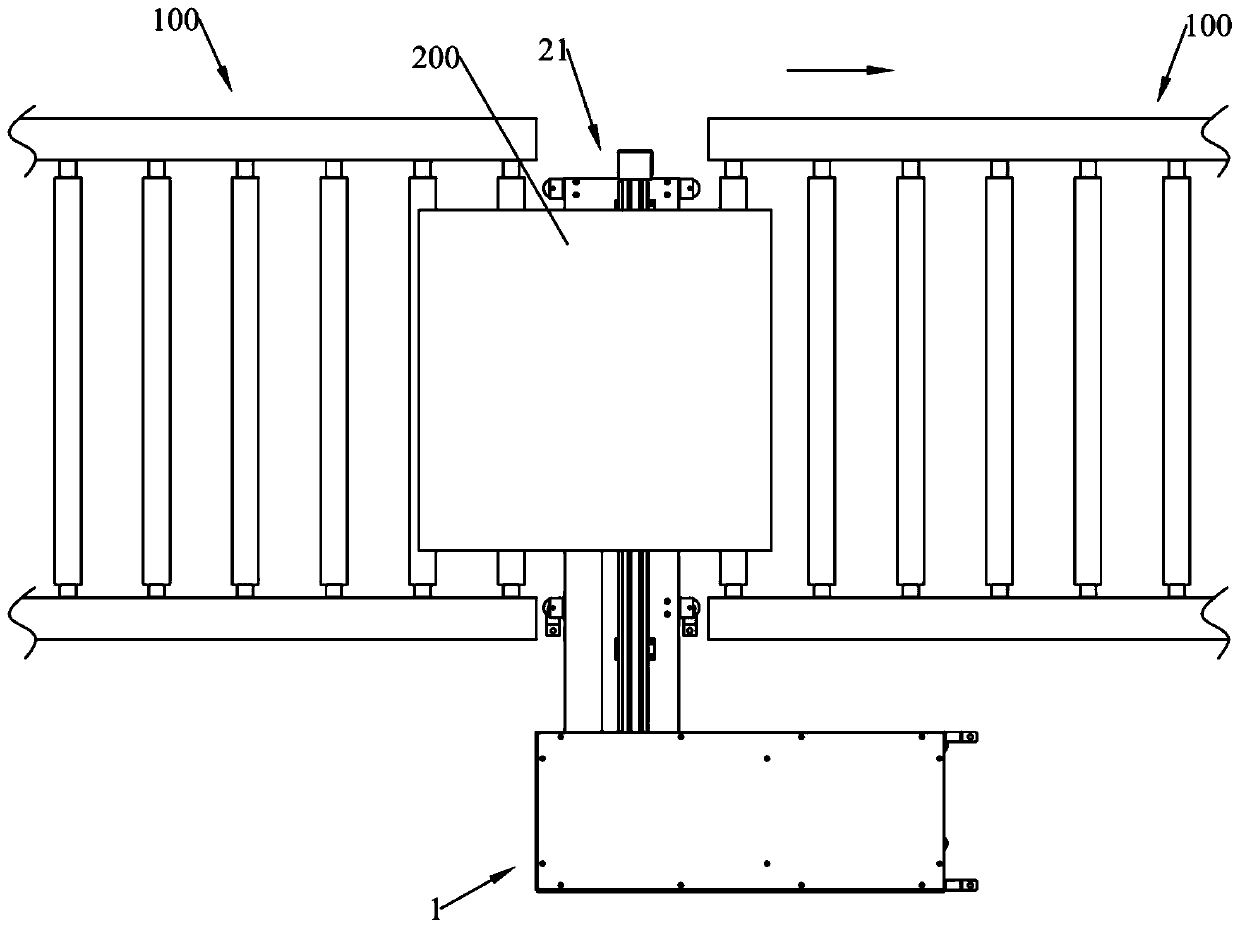

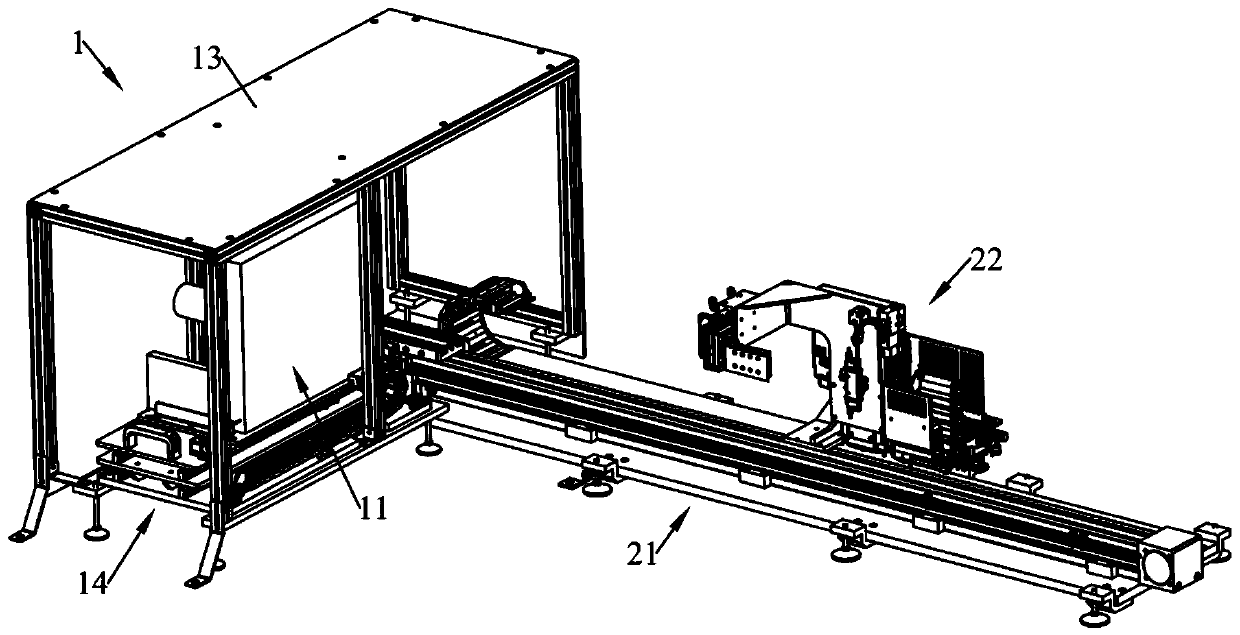

[0046] The invention provides a labeling device, which is used for labeling objects to be labeled, such as packaging boxes. In this embodiment, the labeling of a packaging box is taken as an example for introduction. Such as Figure 1-Figure 3 As shown, the labeling device includes a labeling mechanism 1 and a labeling mechanism, the labeling mechanism 1 is configured to provide labels; the labeling mechanism includes a linear drive assembly 21 and a labeling assembly 22 connected to the output end of the linear drive assembly 21, The linear drive assembly 21 is configured to be located between two sections of adjacent line bodies 100, and the driving direction of the linear drive assembly 21 is perpendicular to the conveying direction of the line body 100. The label supply mechanism 1 is positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com