Full-automatic material pushing device

A push device, fully automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high labor cost and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

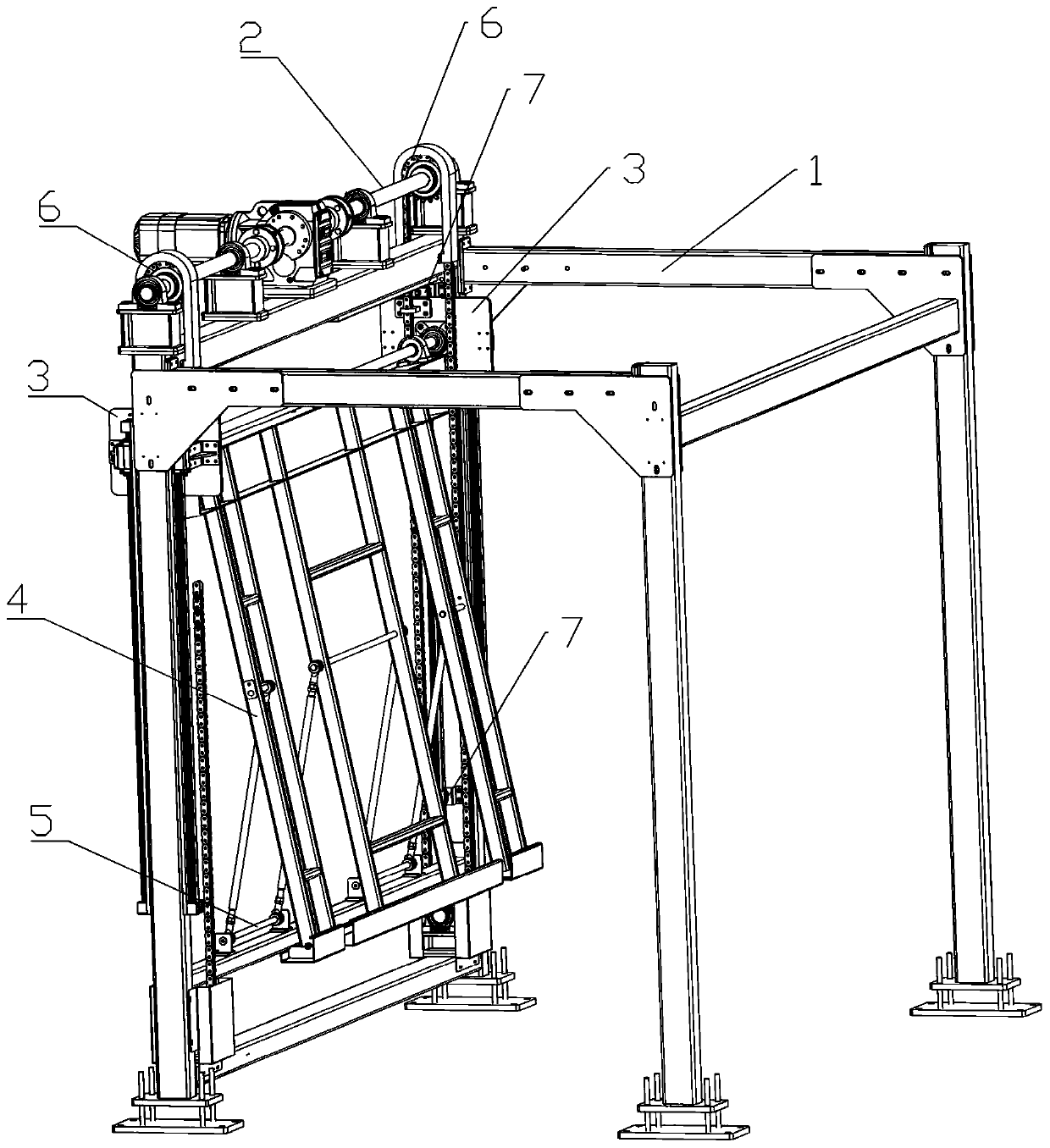

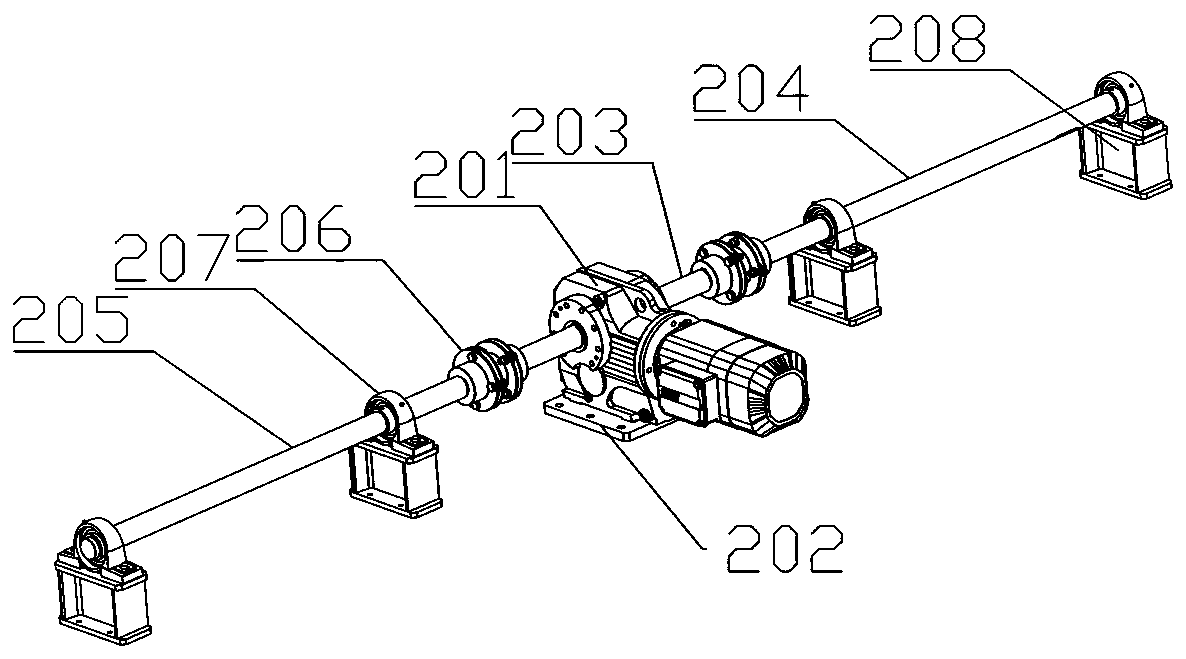

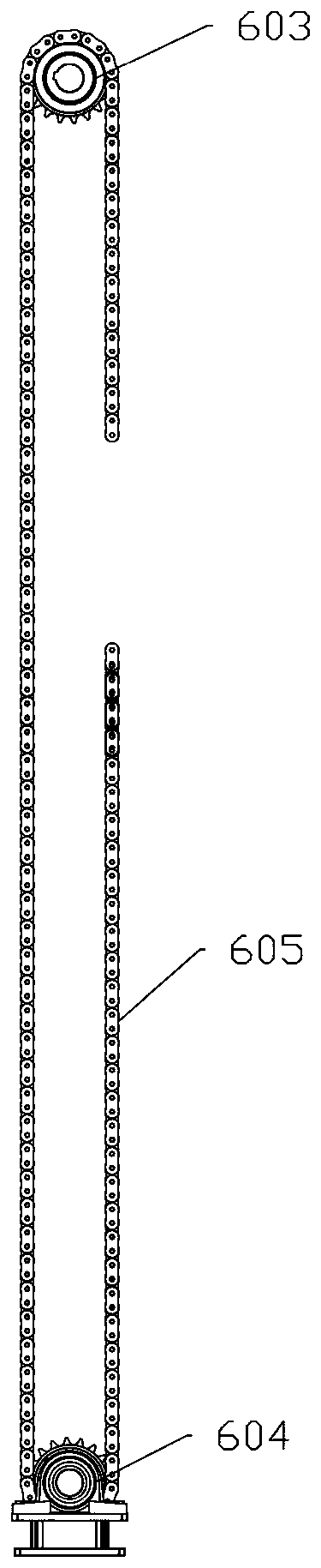

[0114] Such as Figure 1-8 As shown, in this embodiment, the fully automatic material pushing device of the present invention comprises:

[0115] Push rod mechanism 4, used to push materials;

[0116] The column lifting mechanism is connected with the upper part of the push rod mechanism 4, and is used to drive the upper edge of the push rod mechanism 4 to move up and down, and the column lifting mechanism also plays a supporting role;

[0117] The pull rod mechanism 5 is connected with the column lifting mechanism and hinged with the push rod mechanism 4; it is used to push the push rod mechanism 4 to move back and forth;

[0118] The controller is connected with the column lifting mechanism.

[0119] In this embodiment, the column lifting mechanism includes a bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com