Railway loading, unloading and transferring device

A transfer device, railway technology, applied in the direction of lifting device, etc., can solve the problem that the lifting device is not suitable for loading and unloading and transfer, and achieve the effect of convenient loading, unloading and transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

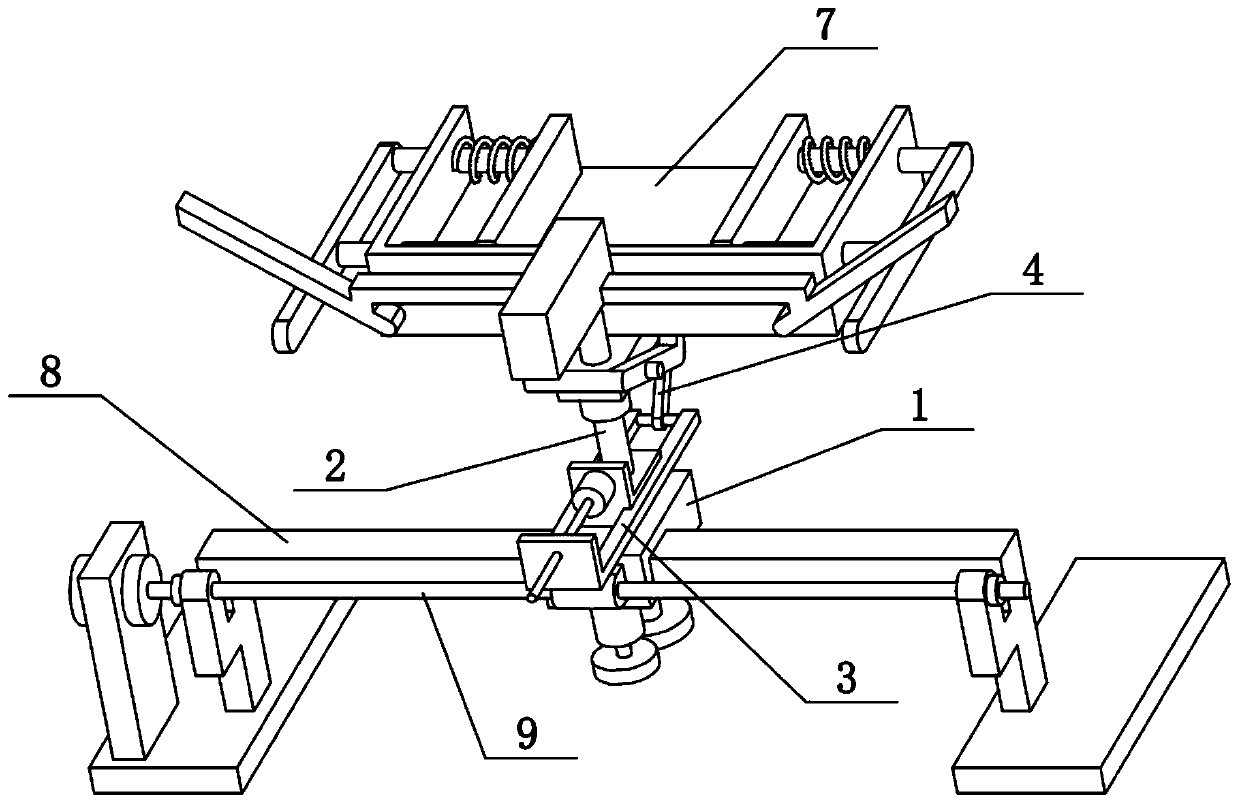

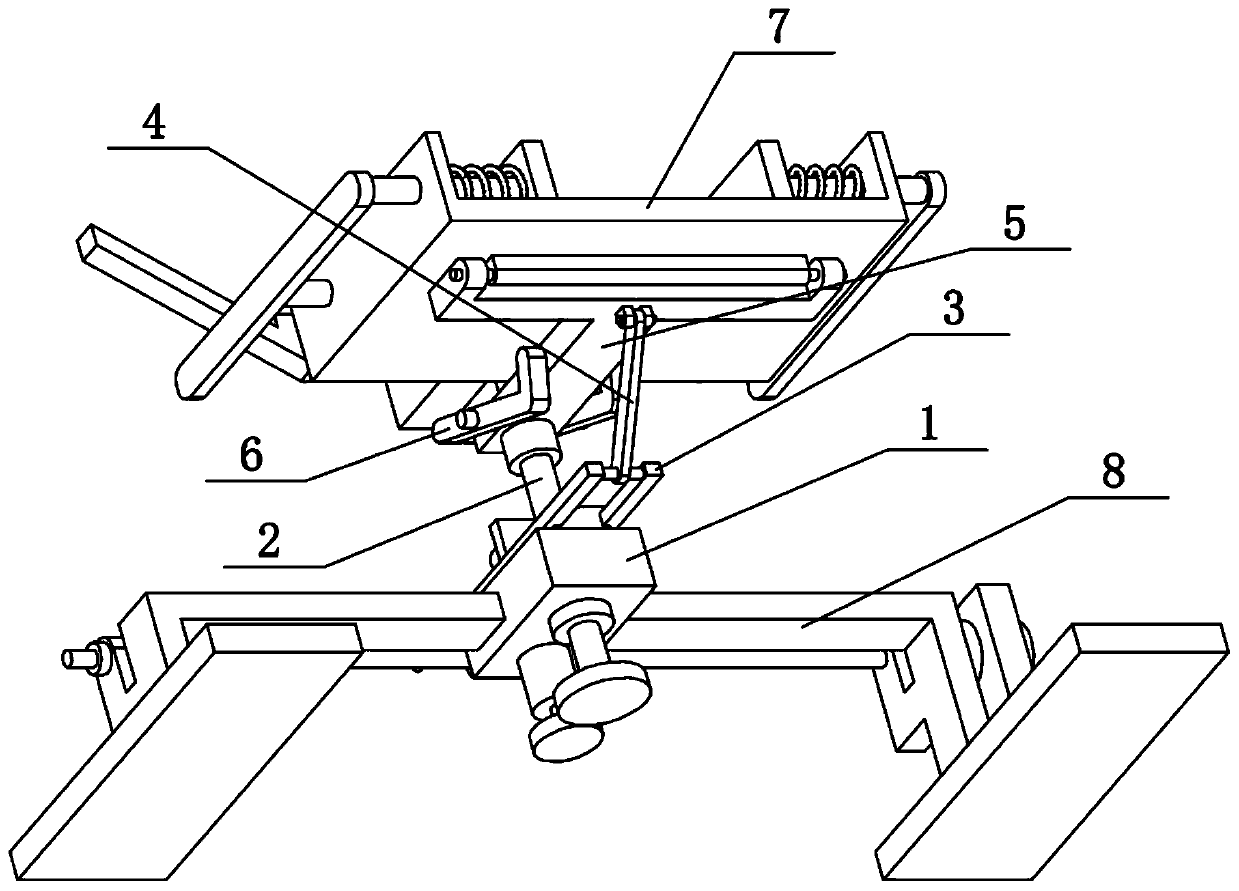

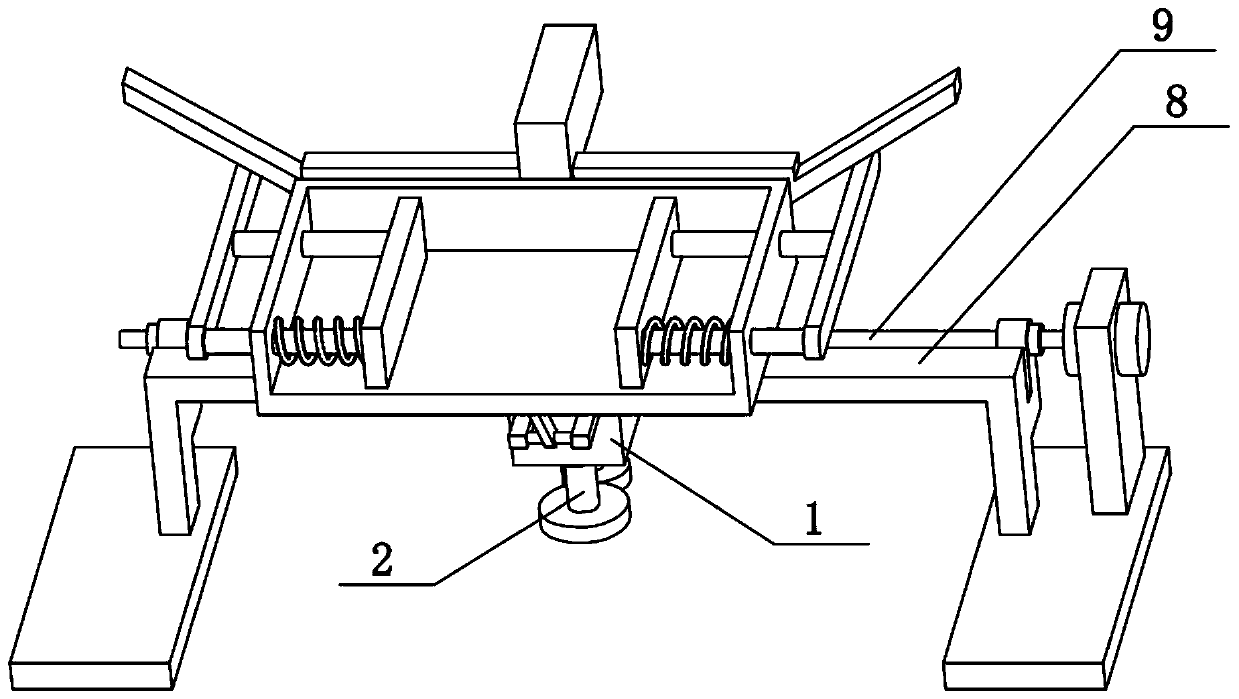

[0036] Combine below Figure 1-14 Describe this embodiment, the present invention relates to the railway field, more specifically a railway loading and unloading transfer device, including a sliding seat 1, a vertical shaft 2, a pallet 5, a hinged seat 51, a sliding cylinder 52, a loading and unloading box 7 and a hinged joint The bump 71, the present invention can lift the goods from low to high on the railway, and after lifting, the loading and unloading box 7 unloads the goods, which is convenient for loading, unloading and transshipment on the railway.

[0037] The vertical shaft 2 is rotatably connected to the sliding seat 1, the front side of the supporting plate 5 is provided with a sliding cylinder 52, and the sliding cylinder 52 is slidably connected on the vertical shaft 2, and the rear side of the supporting plate 5 is provided with a hinged seat 51, The lower side of the loading and unloading box 7 is provided with a hinged projection 71 , which is hingedly connect...

specific Embodiment approach 2

[0039] Combine below Figure 1-14 To illustrate this embodiment, the railway loading, unloading and transshipment device also includes a fixed block 21, a parallel rod 3, a threaded orifice plate 31 and an oblique connecting rod 4, the vertical shaft 2 is fixedly connected with the fixed block 21, and the parallel rod 3 is provided with two , the two parallel rods 3 are respectively slidably connected to the left and right sides of the fixed block 21, the front ends of the two parallel rods 3 are fixedly connected with a threaded orifice plate 31, and the lower ends of the oblique connecting rods 4 are hingedly connected to the two parallel rods 3 Between the rear ends, the upper end of the oblique connecting rod 4 is hingedly connected to the underside of the supporting plate 5 . The two parallel rods 3 can slide back and forth on the fixed block 21. When the two parallel rods 3 slide back and forth, the inclined connecting rod 4 drives the supporting plate 5 and the sliding ...

specific Embodiment approach 3

[0041] Combine below Figure 1-14 Describe this embodiment, described railway loading and unloading transshipment device also comprises motor II24 and lead screw I25, and the front side of fixed block 21 is fixedly connected with motor II24, and the output shaft of motor II24 is fixedly connected with lead screw I25, and lead screw I25 is threaded Cooperate with the threaded orifice plate 31. When the output shaft of the motor II24 rotates, it can drive the lead screw I25 to rotate around its own axis, and the rotation of the lead screw I25 around its own axis can drive the threaded orifice plate 31 to slide back and forth, thereby realizing the control of the two parallel rods 3 on the fixed block 21. Swipe up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com