Concrete for anchorage zone of highway bridge expansion device and preparation method thereof

A telescopic device and a technology for highway bridges, which are applied in the field of cement concrete building materials, can solve the problems of fewer manufacturers, increased costs, and high costs, so as to reduce maintenance cycles, improve compressive strength and flexural strength, and prevent tension and compression performance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

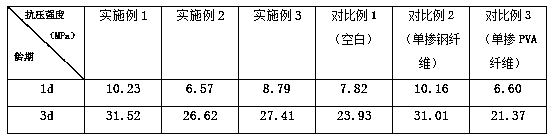

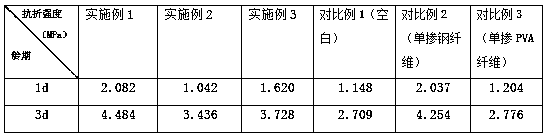

Examples

Embodiment 1

[0028] A concrete for the anchorage area of the telescopic device of a highway bridge, comprising 165.75 parts of water, 414.38 parts of PI52.5 cement, 618.79 parts of sand, 1201.08 parts of stone, 3.108 parts of water reducing agent, 11.28 parts of antifreeze, and 117 parts of steel fiber in parts by mass , PVA fiber 1.09 parts.

[0029] The preparation method of the concrete for the anchorage area of the expansion device of the highway bridge comprises the following steps:

[0030] (1) Weigh the materials in parts by mass;

[0031] (2) Mix sand, stone, antifreeze, steel fiber, and PVA fiber and stir evenly; then add cement in turn and stir evenly, add water and stir for 2 minutes, add water reducing agent and stir for 1 minute, and pour the concrete block after the preparation is completed. Among them, the pouring method is: a. Pour half of the concrete in the test mold, and then place it on the vibrating table to vibrate for 30s; b. Pour the remaining concrete and vibr...

Embodiment 2

[0033] A concrete for the anchorage area of the telescopic device of a highway bridge, including 160 parts of water, 410 parts of PI52.5 cement, 610 parts of sand, 1200 parts of stone, 30 parts of water reducing agent, 110 parts of antifreeze, and 110 parts of steel fiber according to parts by mass , 1 part of PVA fiber.

[0034] The preparation method of the concrete for the anchorage area of the expansion device of the highway bridge comprises the following steps:

[0035] (1) Weigh the materials in parts by mass;

[0036] (2) Mix sand, stone, antifreeze, steel fiber, and PVA fiber and stir evenly; then add cement and stir evenly, add water and stir for 1.5 minutes, add water reducer and stir for 0.5 minutes, and pour the concrete block after the preparation is completed. Among them, the pouring method is: a. Pour half of the concrete in the test mold, and then place it on the vibrating table for 20 seconds; b. Pour the remaining concrete and vibrate for 20 seconds. Un...

Embodiment 3

[0038] A concrete for the anchorage area of the telescopic device of a highway bridge, comprising 170 parts of water, 420 parts of PI52.5 cement, 620 parts of sand, 1210 parts of stone, 4 parts of water-reducing agent, 12 parts of antifreeze, and 120 parts of steel fiber according to parts by mass , 2 parts of PVA fiber.

[0039] The preparation method of the concrete for the anchorage area of the expansion device of the highway bridge comprises the following steps:

[0040] (1) Weigh the materials in parts by mass;

[0041] (2) Mix sand, stone, antifreeze, steel fiber, and PVA fiber and stir evenly; then add cement and stir evenly, add water and stir for 2.2 minutes, add water reducing agent and stir for 1.5 minutes, and pour the concrete block after the preparation is completed. Among them, the pouring method is: a. Pour half of the concrete in the test mold, and then place it on the vibrating table to vibrate for 40s; b. Pour the remaining concrete and vibrate for 40s....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com