Shear connecting piece for corrugated steel web-concrete combined box girder bridge structure

A corrugated steel web and concrete technology, applied in bridge parts, bridges, bridge materials, etc., can solve the problems of large welding workload, obvious space effect, poor bearing capacity, etc. The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

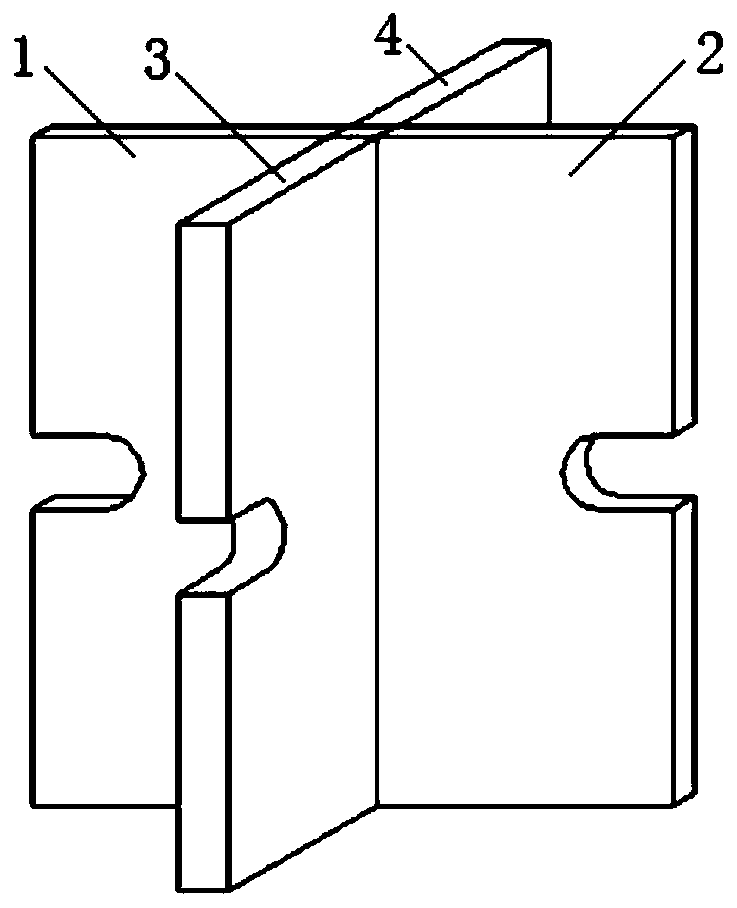

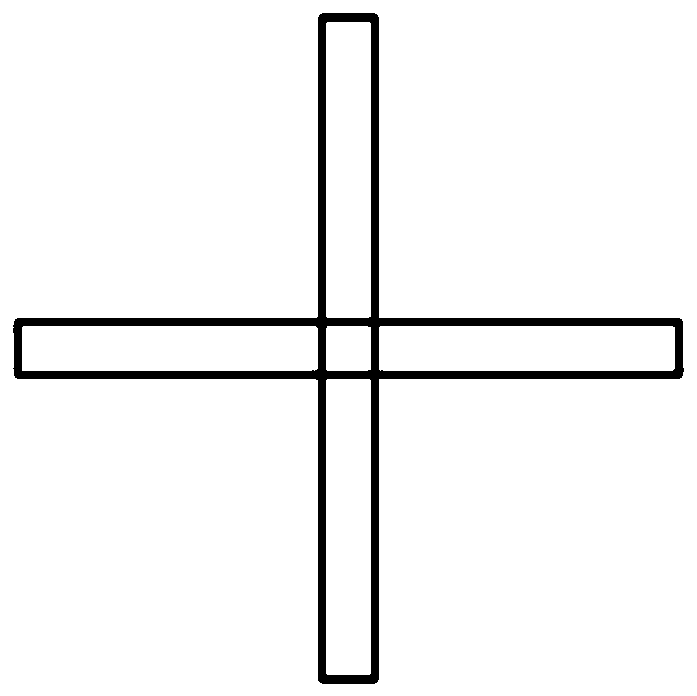

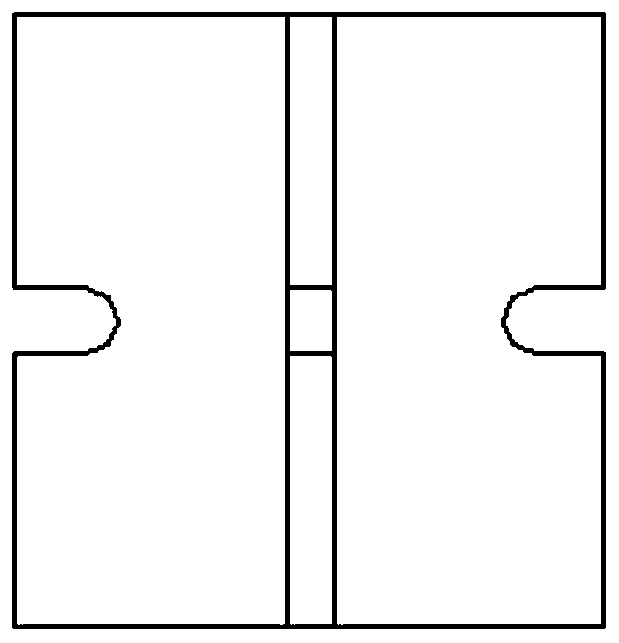

[0027] Such as Figures 1 to 3 As shown, the shear connector includes the first limb plate 1, the second limb plate 2, the third limb plate 3 and the fourth limb plate 4, and the third limb plate 3 and the fourth limb plate 4 are butt welded to form a vertical plate , the first limb plate 1 is vertically welded to the middle position of the left end face of the vertical plate, the second limb plate 2 is welded vertically to the middle position of the right end face of the vertical plate, the first limb plate 1 and the second limb plate 2 are aligned left and right, and from the top Looking down, the shear connector is in the shape of a cross; the first limb plate 1, the second limb plate 2, the third limb plate 3 and the fourth limb plate 4 have opening holes for inserting steel bars in the middle positions of the respective outer sides. The hole is "U" shaped. In this embodiment, the first limb board 1 , the second limb board 2 , the third limb board 3 and the fourth limb bo...

Embodiment 2

[0029] Such as Figures 4 to 6 As shown, the structure of the shear connector is basically the same as that of Embodiment 1, the difference is that the shear connector is welded by two angle steel limbs, and the four opening holes are correspondingly opened on the four sides of the two angle steel (limbs).

[0030] The method for using the shear connector for the corrugated steel web-concrete composite box girder bridge structure of the present invention is:

[0031] Such as Figure 7 As shown, the concrete roof and floor are set on the corrugated steel web, and multiple cross-shaped shear connectors are arranged on the concrete roof and floor in an array and fixed by welding. Horizontal and longitudinal steel bars alternately pass through the opening holes on the corresponding shear connectors. After the steel bars are arranged, multiple cross-shaped shear connectors and horizontal and longitudinal steel bars form a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com