Prefabricated bridge falsework system

A prefabricated and bridge technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of unstable operation of workers, many uncertain factors, and low safety factor, so as to achieve overall stability and increase safety guarantees , The effect of saving input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

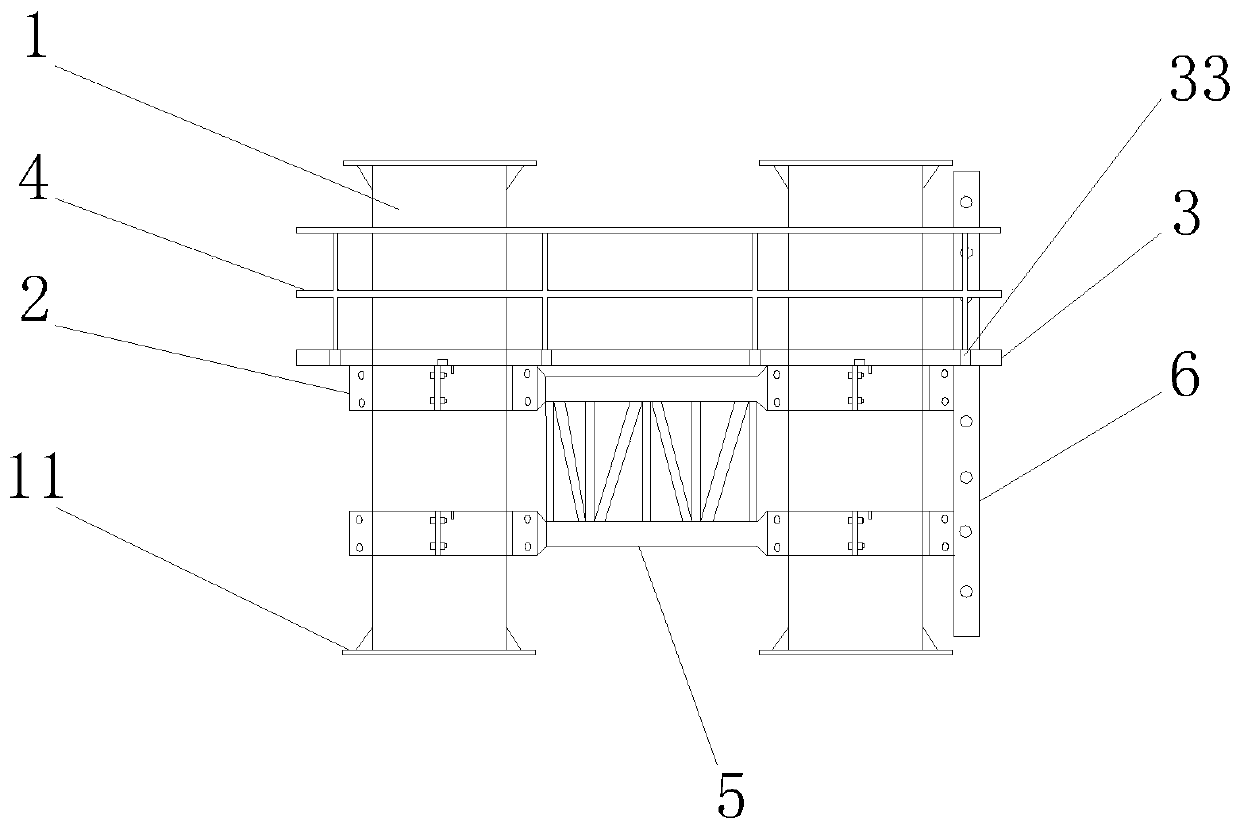

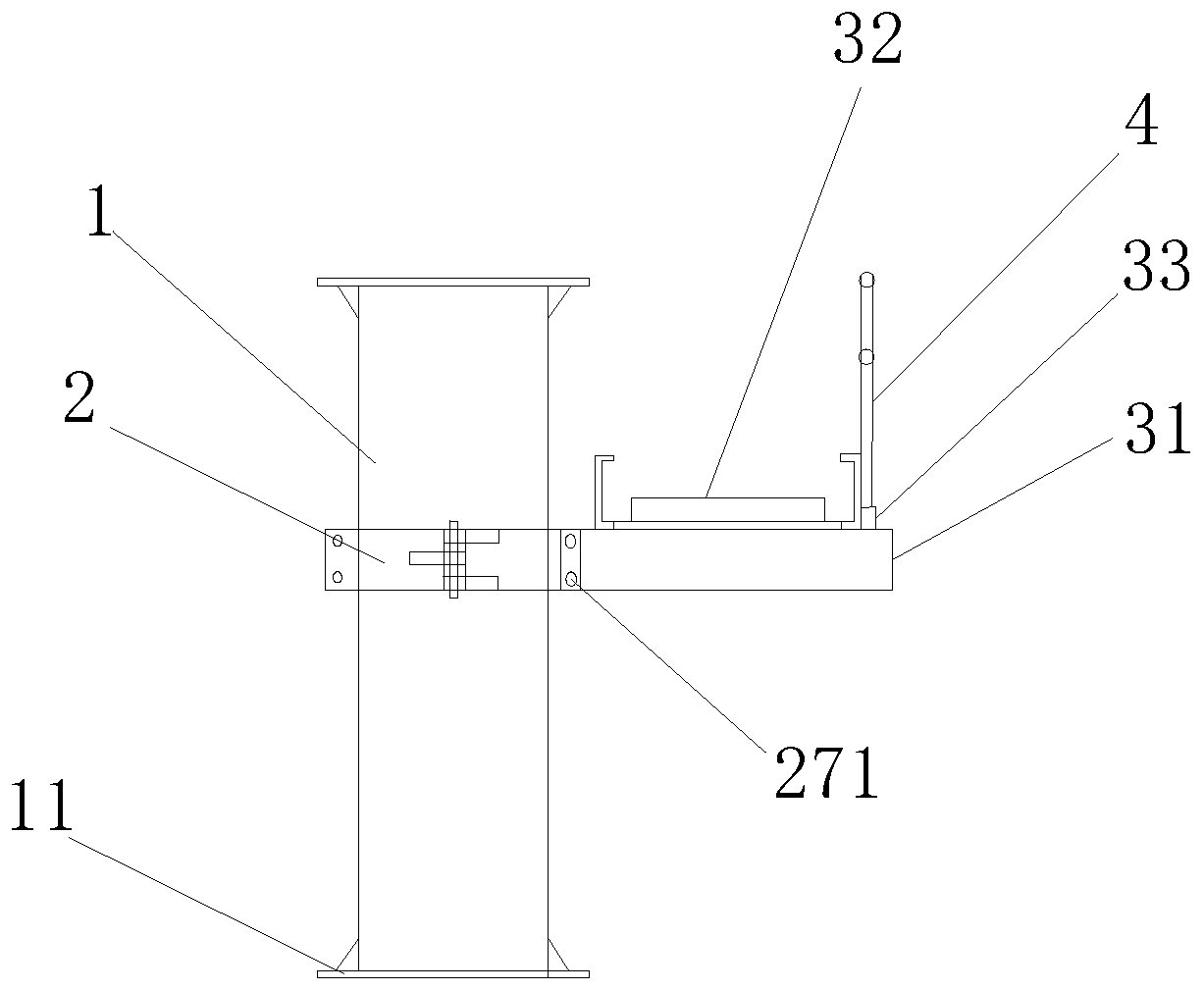

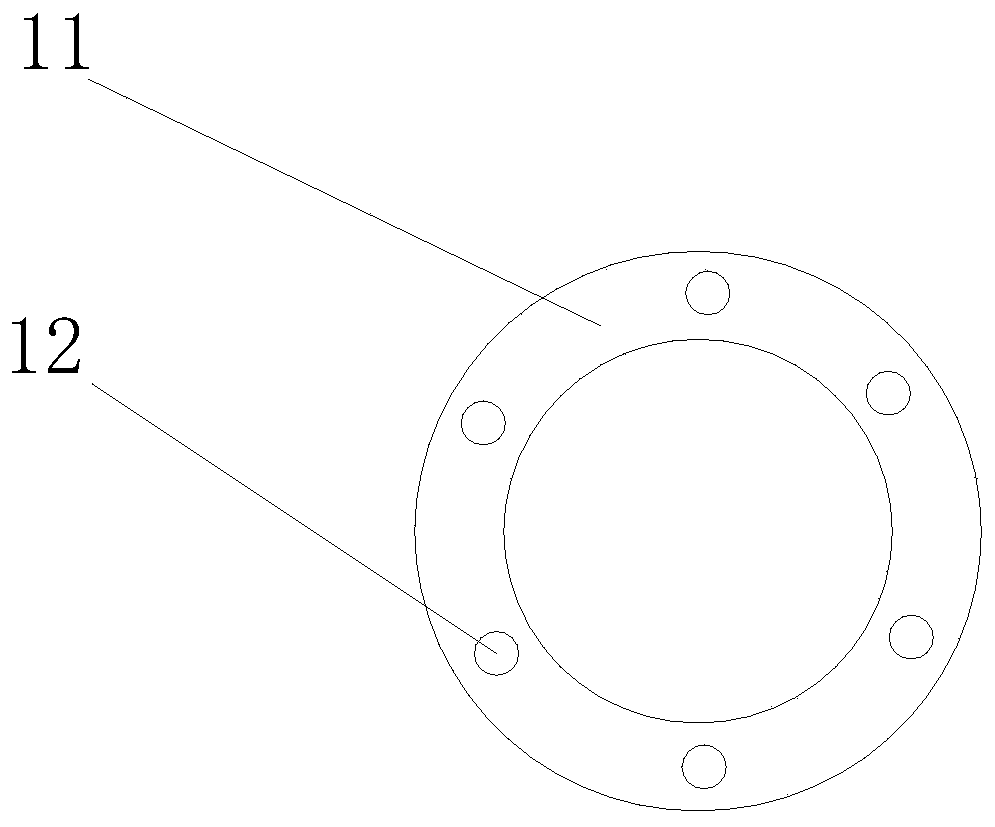

[0032] Please refer to Figure 1-11 , a prefabricated bridge support system of the present invention, comprising a plurality of prefabricated steel columns 1, a multifunctional hoop 2 is set on the prefabricated steel uprights 1, and a multifunctional hoop 2 is set on the multifunctional hoop 2 An installation and disassembly platform 3 is provided with a guardrail 4, and a scissors support truss 5 is arranged between two adjacent assembled steel columns 1, and the scissors support truss 5 is connected to the multi-functional embrace The hoop 2 is connected, and a ladder 6 is provided on one side of the installation and disassembly platform 3. The ladder 6 is connected with the multifunctional hoop 2, and the assembled steel column 1, the multifunctional hoop 2, the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com