Coating device for waterborne epoxy anticorrosive paint

An anti-corrosion coating, water-based epoxy technology, applied in mixers, mixers, buildings and other directions with rotary stirring devices, can solve problems such as excessive humidity, wasting time, and staff fatigue, and achieve enhanced anti-corrosion function and simple equipment structure. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

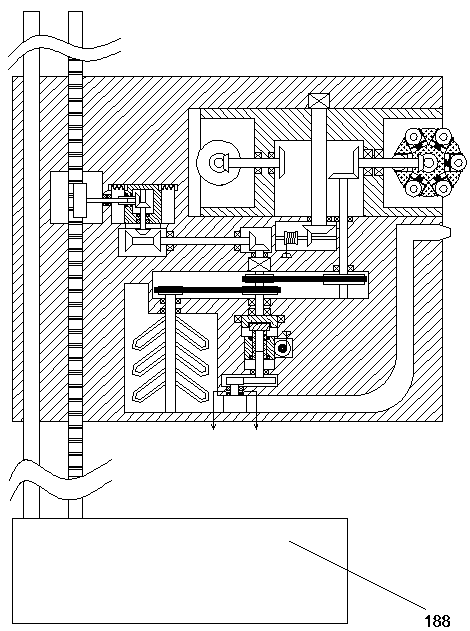

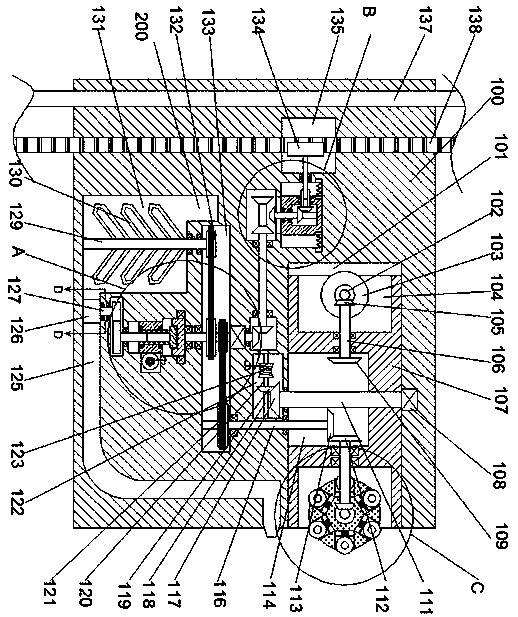

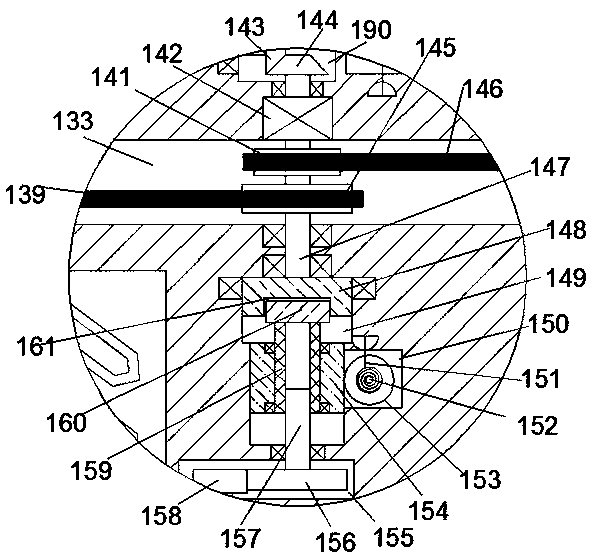

[0017] Such as Figure 1-Figure 6As shown, the brushing equipment of a kind of waterborne epoxy anticorrosion paint of the present invention comprises main body 100, and the left side end surface of described main body 100 is provided with rotating chamber 101, and the rotation in described rotating chamber 101 is provided with first Rotating block 107, first grooves 104 are symmetrically opened on the left and right sides of the first rotating block 107, and second grooves 114 with openings facing downwards are arranged between the first grooves 104, the rotating A first motor 108 is fixed in the top wall of the cavity 101, and the bottom end of the first motor 108 is connected with a rotating shaft 111 extending downward, and the rotating shaft 111 is fixedly arranged with the first rotating block 107. The first rotating shaft 106 is rotated in the left end wall of the first groove 104, the right end of the first rotating shaft 106 is fixed with a first bevel gear 109, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com