Temperature control system of mass concrete temperature measuring line

A technology of mass concrete and temperature control system, applied in thermometer parts, thermometers, measuring devices, etc., can solve the problems of reducing the installation efficiency of the temperature control system, easily causing temperature stress, information transmission structure interference, etc., to enhance the work Efficiency and practical value, increase anti-corrosion function, improve the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

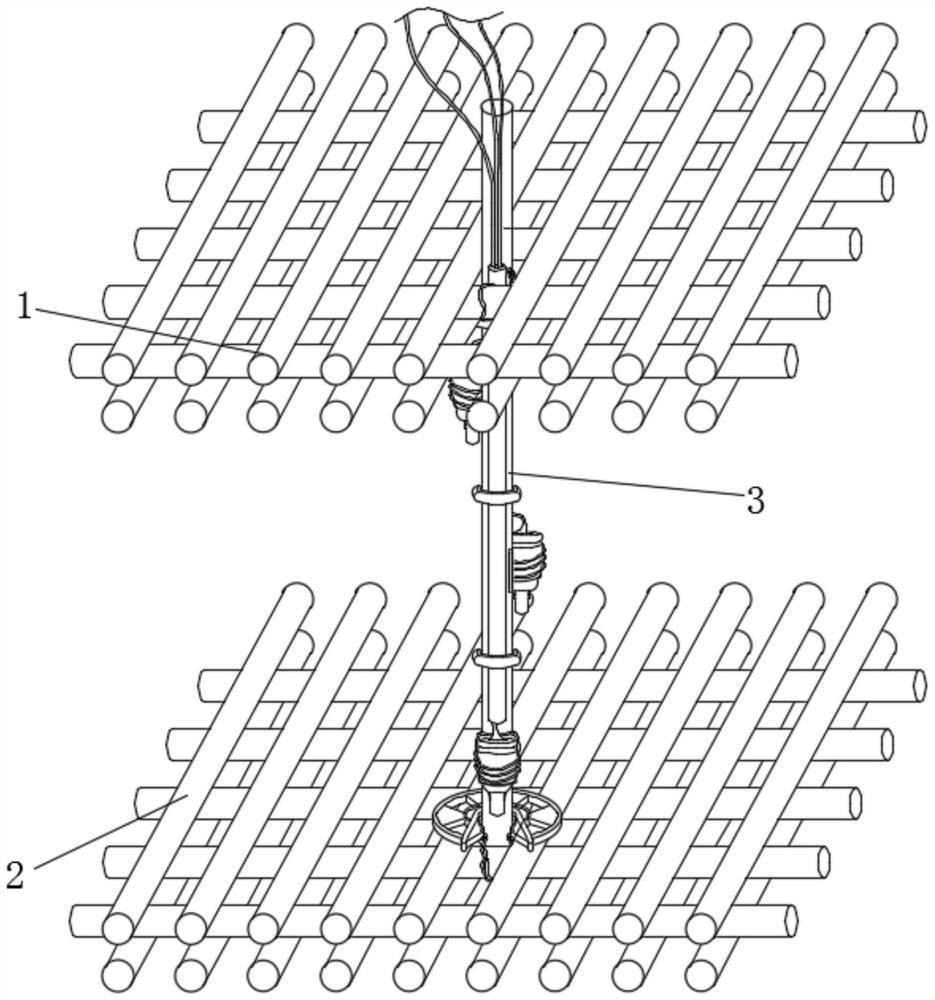

[0026] Example 1, such as Figure 1-2 As shown, through the structural installation of the corresponding vertical plane at the intersection of the reinforcement grid 1 and the reinforcement grid lower reinforcement 2, multiple attached reinforcement bars 3 and the temperature control monitoring system can be vertically assembled on the reinforcement grid reinforcement 1 and the reinforcement mesh At the intersection of the ribs 2, the temperature measuring line of the corresponding area can be installed according to the mass concrete area, and the internal temperature of the mass concrete can be accurately monitored in real time.

Embodiment 2

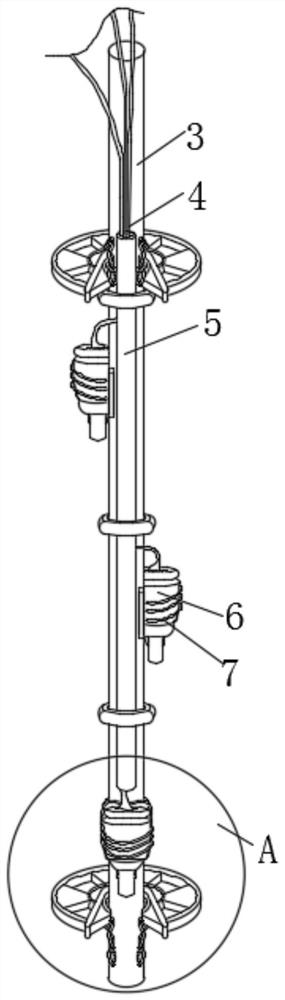

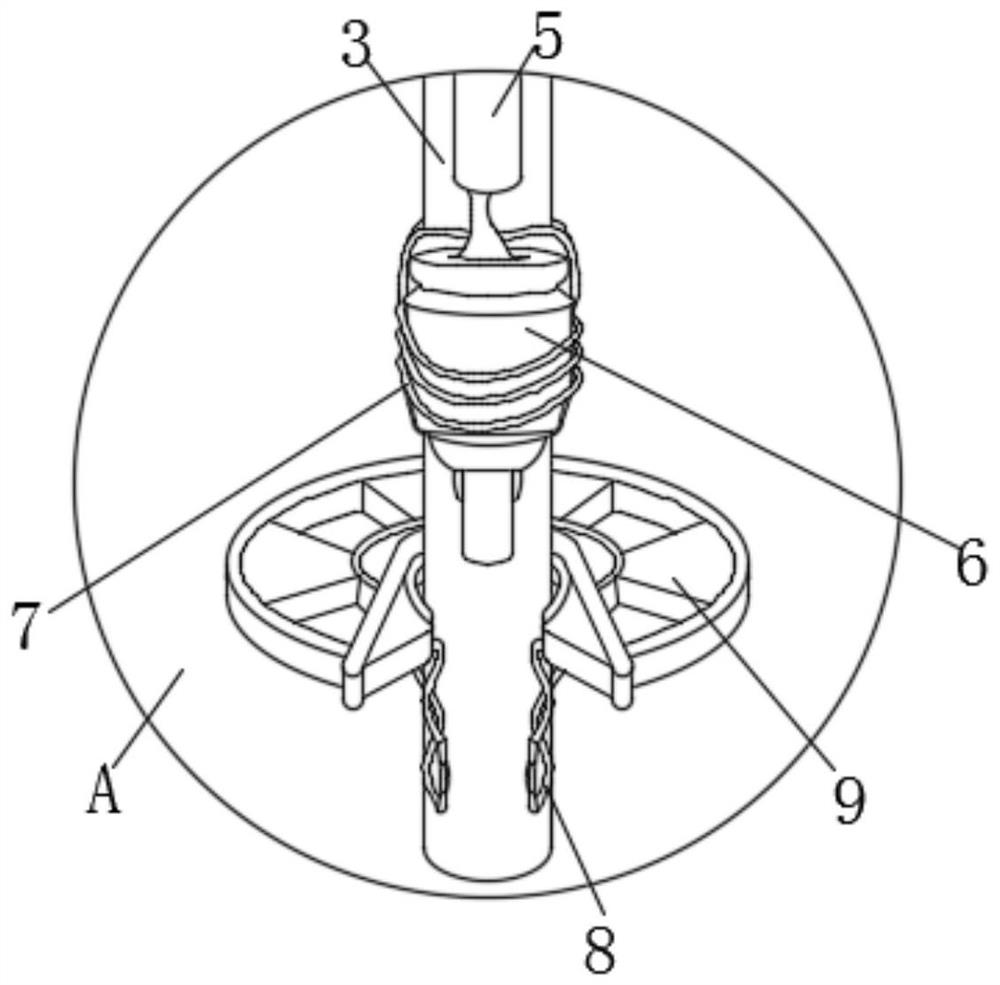

[0027] Example 2, such as Figure 2-4 As shown, when the three sets of sensors 6 are respectively assembled on the top, bottom, and middle position outside the attached steel bar 3, the barrel body 51 can be fixed on one end of the attached steel bar 3 through three sets of fixing clips 52, and then the The sensor 6 and the lead wire 4 at the bottom are inserted and guided, and the sensor 6 and the lead wire 4 at the middle position and the top can be inserted and guided under the corresponding opening of the through hole 53, so that the three sets of the lead wire 4 are integrated together, and the The outside of the set of lead wires 4 forms a protection system for protection, increasing the operability and convenience of connecting the three sets of lead wires 4 to the plug 10 and the temperature control data collector 11, and improving the anti-corrosion effect of the three sets of lead wires 4 embedded in the concrete.

[0028] Working principle: When the temperature cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com