Preparation method of fence pole

A technology of fences and bamboo poles, which is applied in the fields of fish farming, application, climate change adaptation, etc., can solve the problems of corrosion-prone, large manpower, anti-corrosion of fence poles, aquaculture fence net clothing, sewage-proof aquaculture fence net clothing, and poor water exchange between inside and outside To achieve the effect of reducing the damage of breeding objects, reducing the number of rod changes and improving the anti-corrosion function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings:

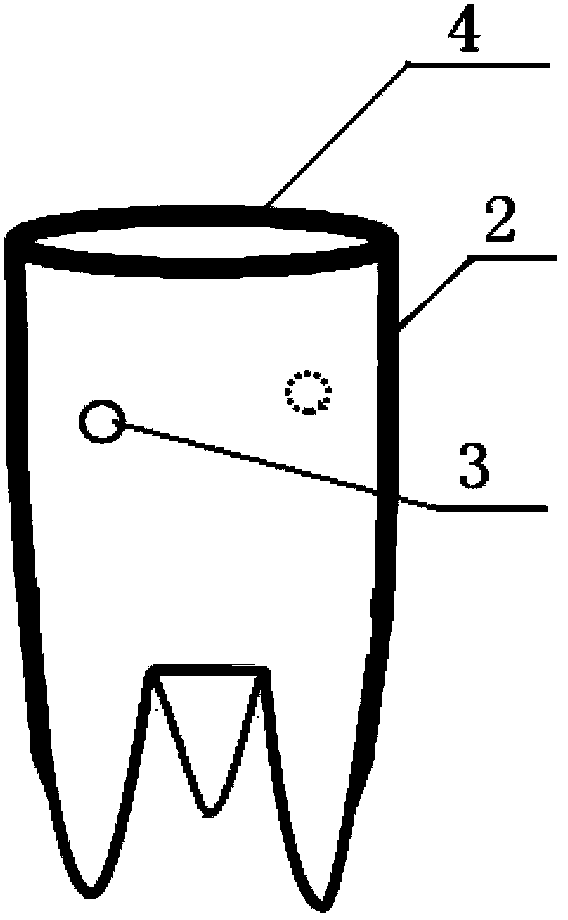

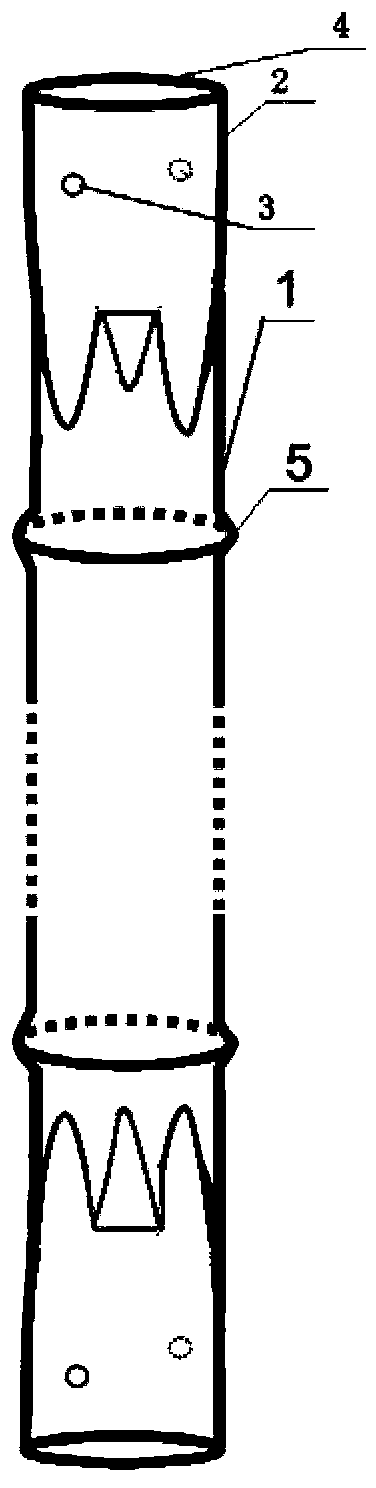

[0009] The present invention selects straight bamboo poles 5 with a length of 2m to 6m and an outer diameter of 30mm to 60mm; the hollow high-density polyethylene casing 2 with a plug is made of high-density polyethylene with anti-corrosion function, and the hollow high-density polyethylene casing The length of the tube is 110mm-130mm, the inner diameter is 30mm-60mm, the thickness of the hollow high-density polyethylene casing is 3mm-5mm, the plug 4 is located at one end of the hollow high-density polyethylene casing, and the thickness of the plug is 2mm-4mm; The hollow high-density polyethylene sleeve pipe with plug is tightly set on the upper and lower ports of the above-mentioned straight moso bamboo pole respectively, and ensures that the port of the straight moso bamboo pole is close to the plug of the hollow high-density polyethylene sleeve pipe; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com